Cooking process of cooking machine

A cooking machine and cooking technology, which is applied to timing control ignition mechanism, utensils with integral electric heating device, plug-in, etc., which can solve the problems of taste, stir-frying, general effect of ripening, burnt ingredients, poor cooking technology, etc. , to achieve the effect of retaining nutrients and ripening effect, improving the taste and ensuring the ripening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

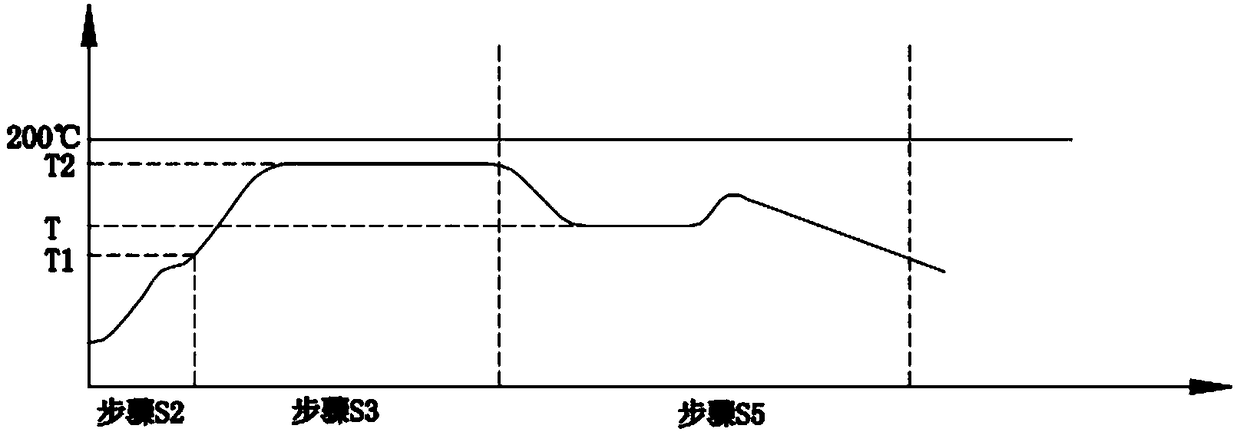

[0027] In this embodiment, meat slices and green peppers are the main ingredients, and the auxiliary materials are edible oil, salt, vinegar, etc., to illustrate the beneficial effect of using the technology of the present invention to fry green pepper fried meat.

[0028] For details, please refer to figure 2 Process temperature curve figure of the present invention, concrete process is as follows:

[0029] Step S1: In the stage of adding ingredients, pour cooking oil into the bottom of the frying pan, add meat slices, green peppers, other salt, vinegar and other auxiliary materials, close the lid and start; the cooking machine starts to work, and enters the first heating stage;

[0030] Step S2: In the first heating stage, the heating device heats the wok with the set power P1 until the temperature in the wok reaches T1, the T1 is 80°C to 120°C, and the P1 is 1000W to 2200W. During this period, the stirring shovel stops and enters Step S3: Of course, those skilled in the a...

Embodiment 2

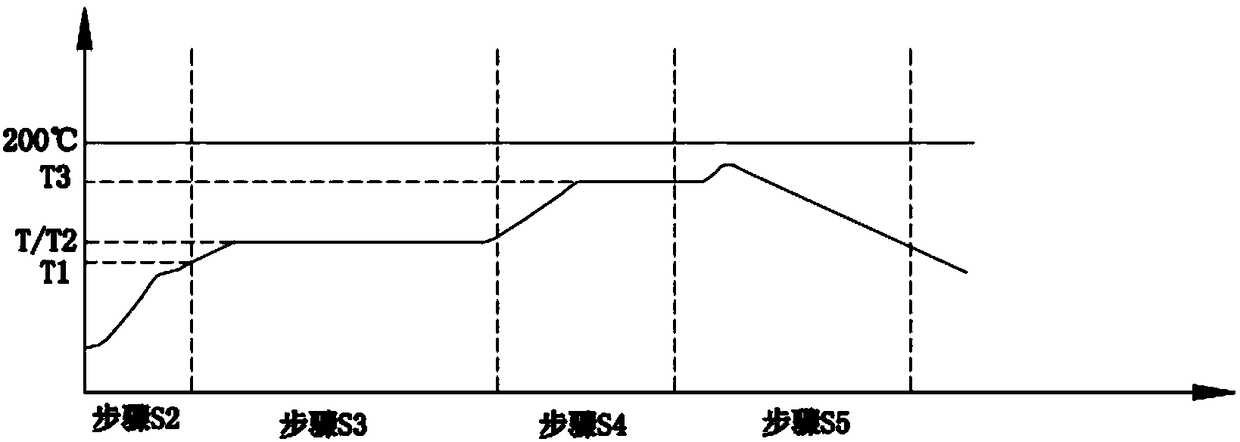

[0041] In this embodiment, Chinese cabbage is used as the main food material, and edible oil, salt, vinegar, dried red pepper, etc. are used as auxiliary materials, and the beneficial effect of frying hot and sour Chinese cabbage with the technology of the present invention is illustrated.

[0042] For details, please refer to image 3 Process temperature curve figure of the present invention, concrete process is as follows:

[0043] Step S1: In the stage of adding ingredients, pour cooking oil into the bottom of the wok, add ingredients such as cabbage, a little dried red pepper, salt, vinegar and other auxiliary materials, close the lid and start; the frying machine starts to work, and enters the first heating stage;

[0044] Step S2: In the first heating stage, the heating device heats the wok with the set power P1 until the temperature in the wok reaches T1, the T1 is 80°C to 120°C, and the P1 is 1000W to 2200W. During this period, the stirring shovel stops and enters Ste...

Embodiment 3

[0054] This embodiment discloses the process of making soup or stew using a cooking machine. For details, see Figure 4 , the main process steps are as follows:

[0055] Step S1: In the stage of adding ingredients, pour cooking oil into the bottom of the wok, add ingredients, salt, water and other auxiliary materials, close the lid of the pot and start; the cooking machine starts to work, and enters the first heating stage;

[0056] Step S2: In the first heating stage, the heating device heats the wok with the set power P1 until the temperature in the wok reaches T1, the T1 is 80°C to 120°C, and the P1 is 1000W to 2200W, during which the stirring shovel stops and enters Step S3: For the convenience of description in this embodiment, the set power P1 is specifically 1400W, and the T1 is 80°C to 95°C. That is to say, in the first heating stage when 1600W is used, the temperature in the wok is heated to 80°C to 95°C. Due to the stew or soup, water will be added to the wok, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com