Pull-rod-self-bucking type motor fan cover

A technology of pull rod and wind cover, which is applied in the field of pull rod self-locking motor wind cover, which can solve the problems of increased vibration value and noise value of the motor, enlarged vibration and noise of the wind cover, and long process time, so as to reduce vibration and noise, Easy to install and disassemble, and the outer circle of the windshield is compact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

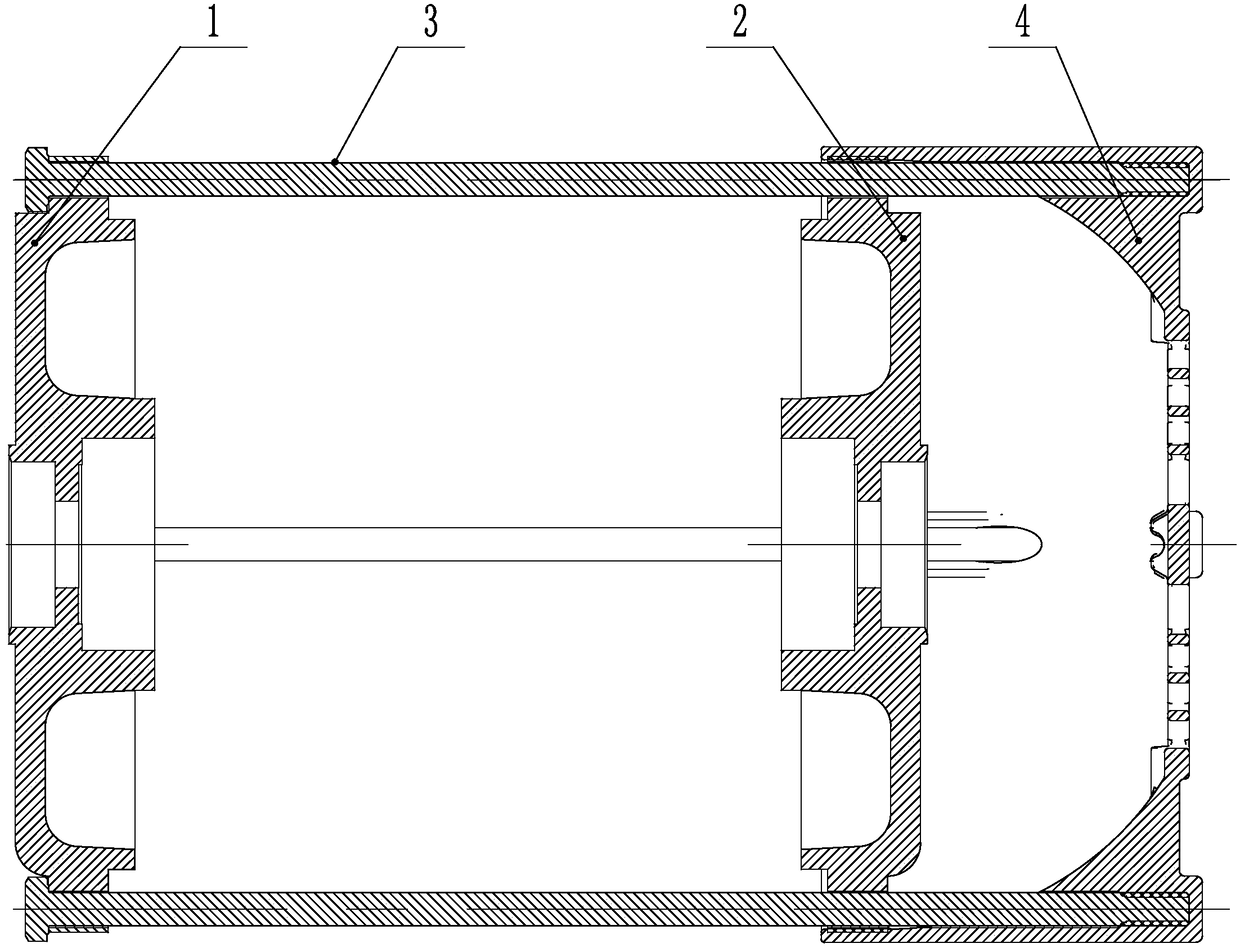

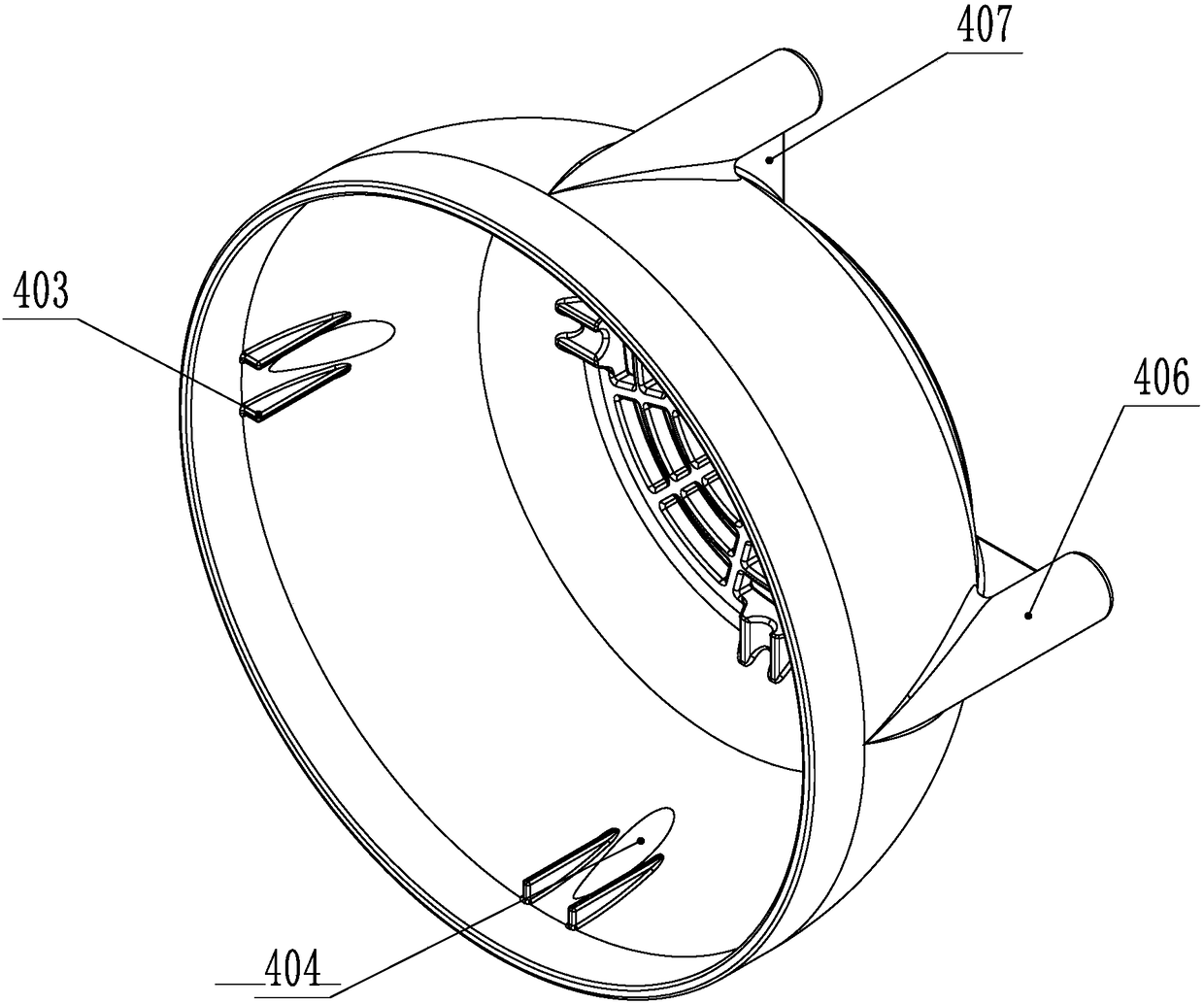

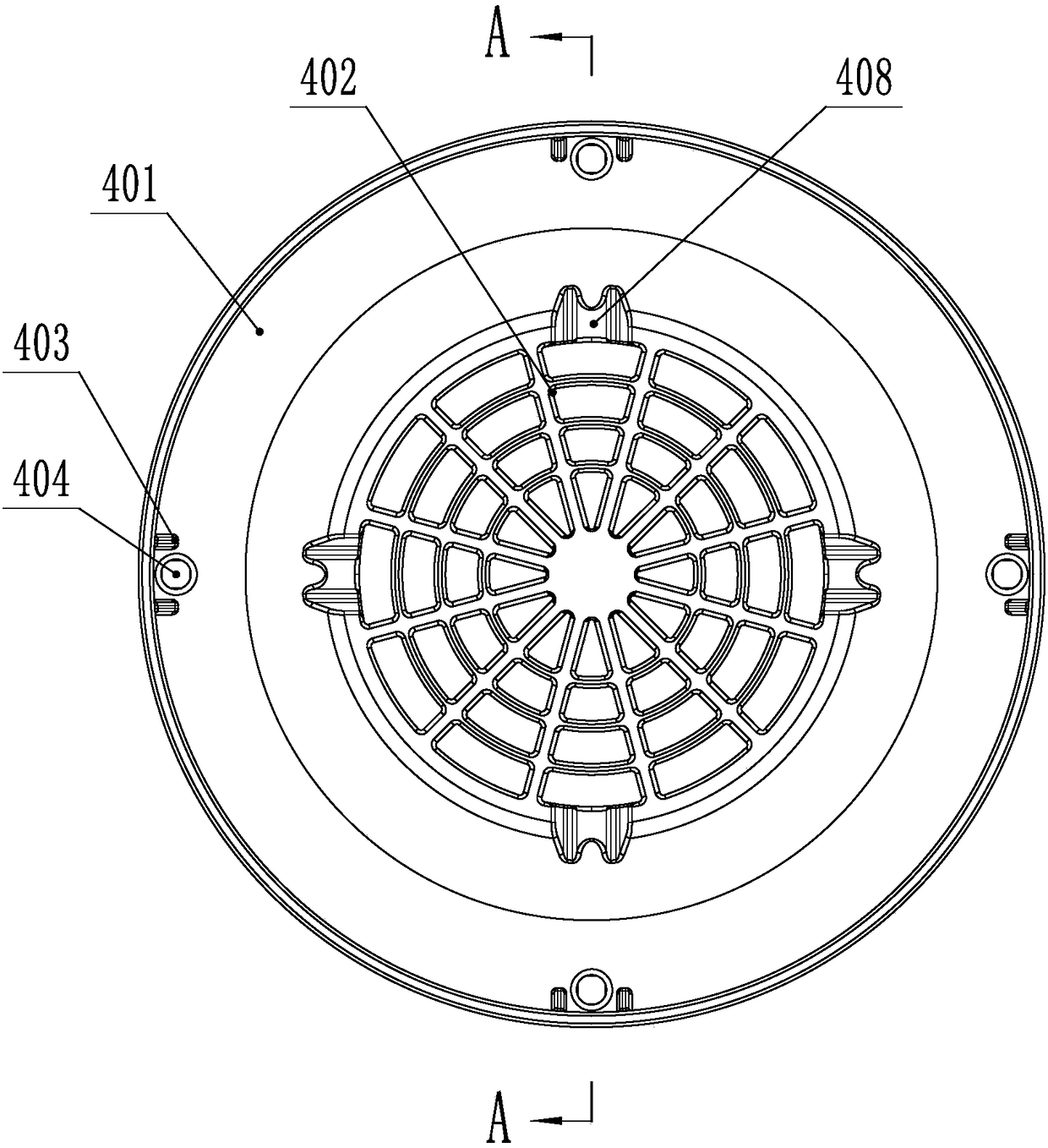

[0024] Such as Figure 1-4 As shown, the pull rod self-locking motor wind cover, the wind cover 4 includes a wind cover ring 401 and an air inlet window 402, the pull rod 3 is screwed into the threaded hole of the rear end cover 2 from the motor front end cover 1, and the rear end of the wind cover ring 401 is in the inner wall. There are four tie rod holes 404 evenly distributed around the upper part for the pull rod 3 to enter, and each tie rod hole 404 is provided with a self-fastening piece 405 that automatically realizes fastening after the tie rod 3 enters, and the tie rod 3 passes through the threaded hole of the rear end cover 2 Then it enters the pull rod hole 404 forward, and is automatically fastened and fixed by the self-fastening piece 405 .

[0025] In order to judge whether the windshield 4 is installed in place, a po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com