Zoom lens unit

A zoom lens and lens technology, which is applied in the field of zoom lenses, can solve the problems of focusing on objects at very close distances, large loads on computing chips, and distortion of resolution, etc., to achieve increased curvature, increased back focus margin space, and improved aberrations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

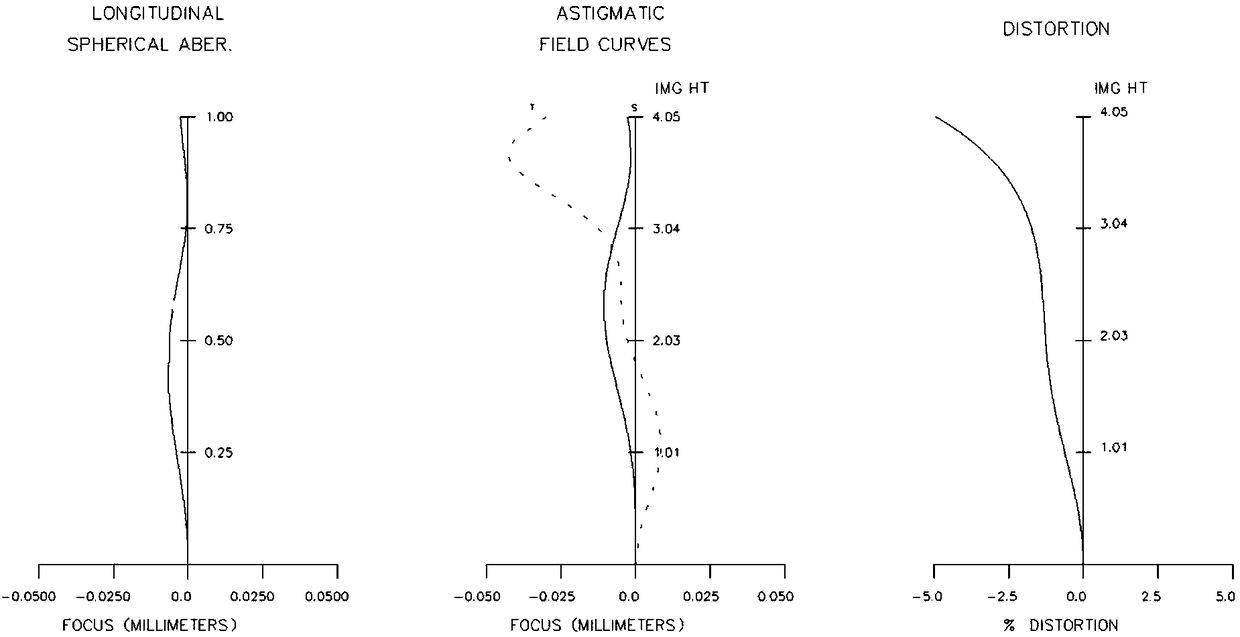

Embodiment 1

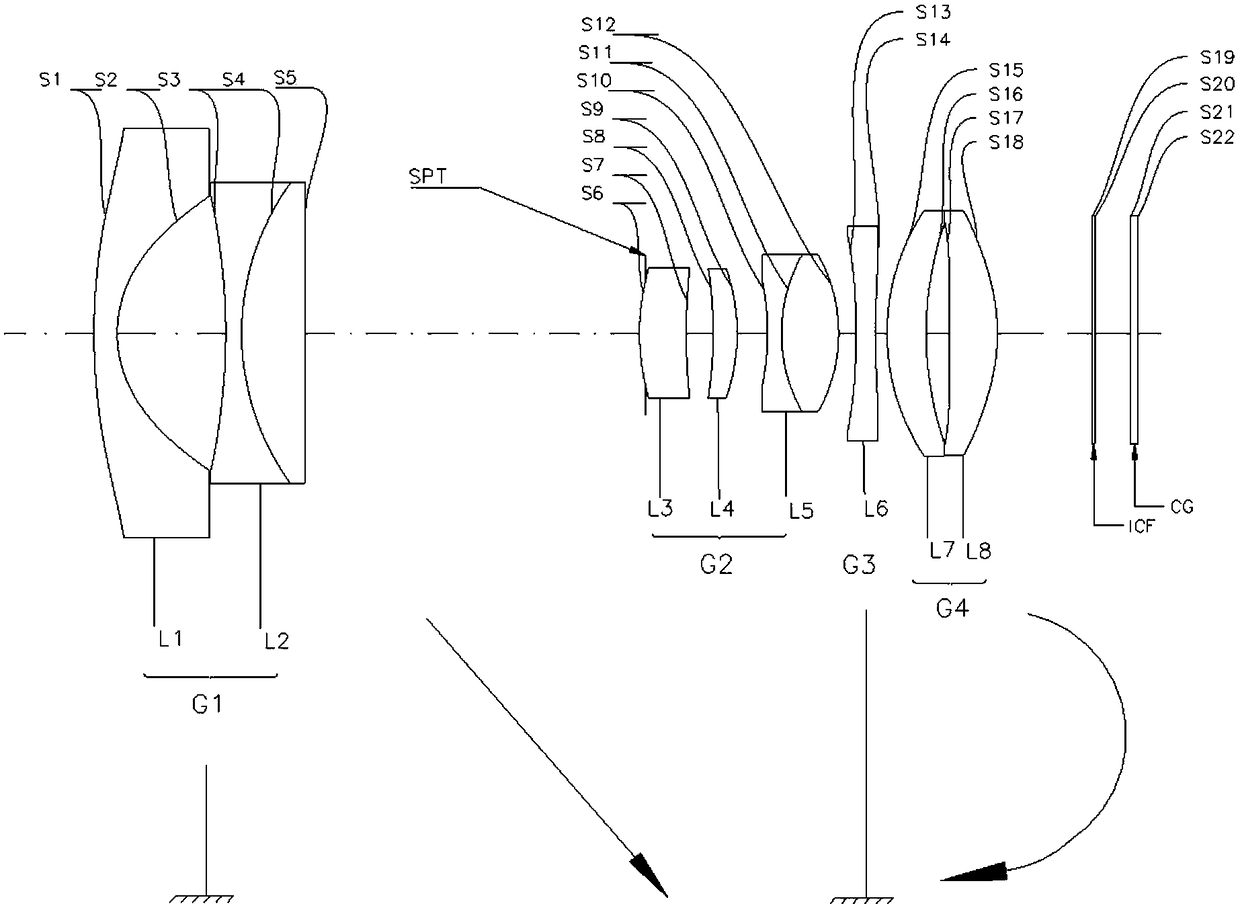

[0042] Such as figure 1 As shown, it is a zoom lens related to this embodiment, which specifically includes: a fixed lens group G1 with negative refractive power, an aperture stop SPT, a zoom lens group G2 with positive refractive power, and a lens group with negative refractive power. The fixed lens G3, the focusing lens group G4 with positive refractive power, and the filter ICF perform zooming from the wide-angle end to the telephoto end by moving the zoom lens group along the optical axis from the image side to the object side. The focus lens group moves along the optical axis to perform correction and focus adjustment of image plane variation accompanying magnification.

[0043] The fixed lens group G1 includes: a first lens L1 with negative refractive power and double-sided aspheric surfaces, and a first cemented lens L2 with positive refractive power.

[0044] The zoom lens group G2 includes: a third lens L3 with positive refractive power and double aspherical surfaces...

Embodiment 2

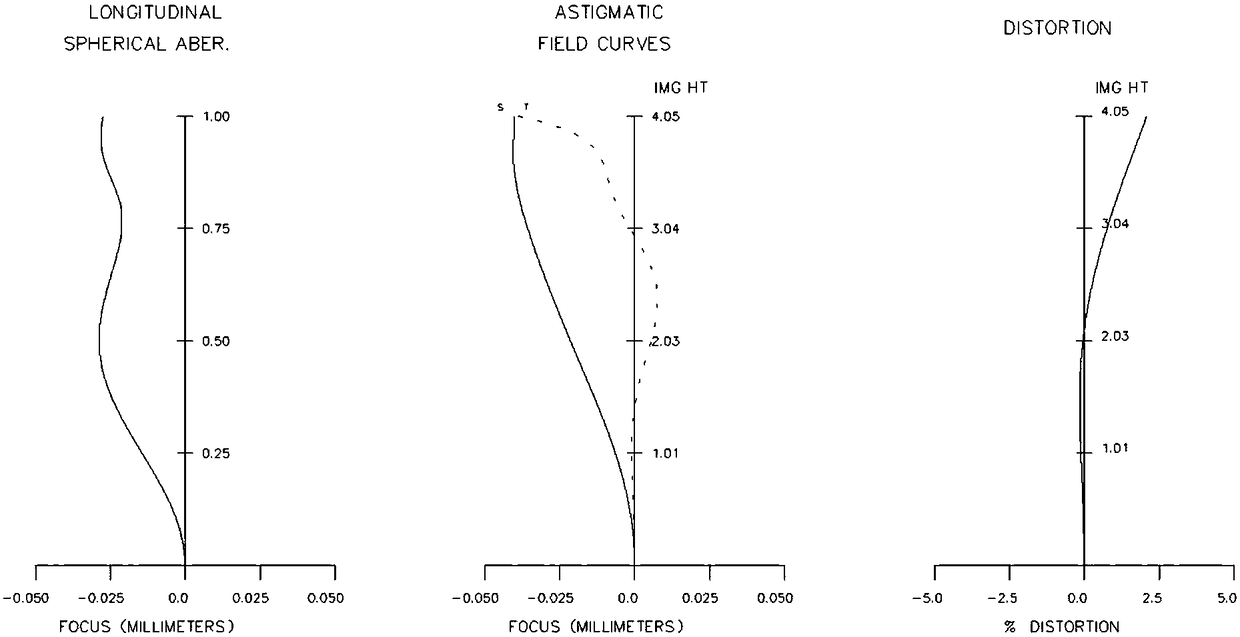

[0060] Such as Figure 4 As shown, compared with Embodiment 1, the focusing lens group G4 in this embodiment adopts the seventh lens L7 with positive refractive power.

[0061] In a state where the fixed lens group and the fixed lens are fixed, the zoom lens group is moved from the object side to the image side along the optical axis to perform zooming from the wide-angle end to the telephoto end. , by moving the focusing lens group along the optical axis, correction and focusing of image plane variation accompanying magnification are performed.

[0062] Various numerical data about the zoom lens of Example 2 are shown below.

[0063] EFL=3.95 wide-angle end~7.90 intermediate focus position~11.40 telephoto end

[0064] FNo=2.52 wide-angle end~3.91 intermediate focus position~4.57 telephoto end

[0065] Table 4 shows the structural parameters of the lens of Example 2; Table 5 shows the zoom parameters of the lens of Example 2; Table 6 shows the aspheric coefficient of the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com