Rotary LED lighting system

An LED lighting, rotary technology, applied in lighting devices, lighting and heating equipment, components of lighting devices, etc., can solve the problems of power loss, increase lighting time, reduce the overall life of products, etc., to reduce generation and deposition, Improved heat dissipation efficiency and approximately constant light intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

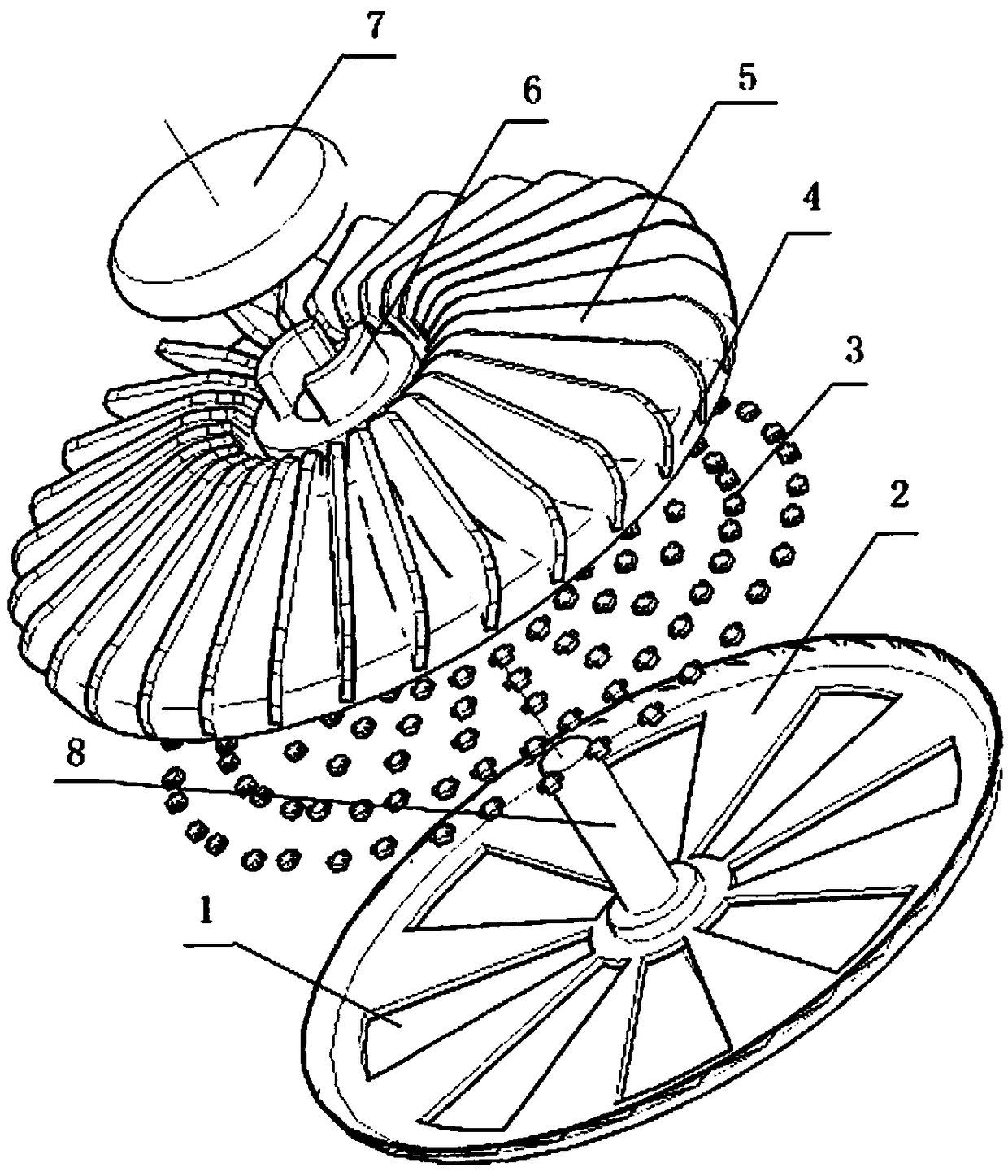

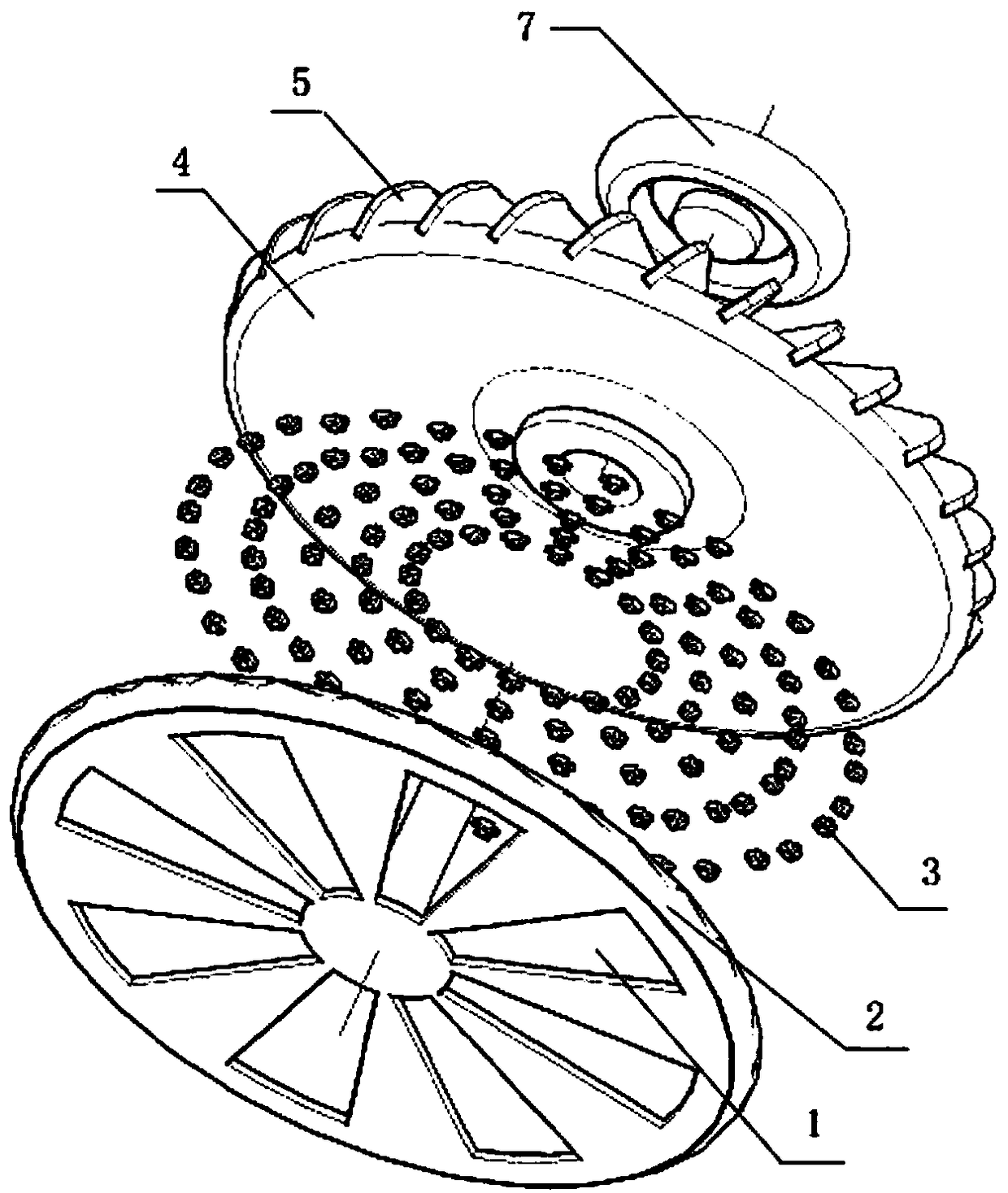

[0016] Such as figure 1 and figure 2 As shown, the LED lamp of the rotating light source includes: a lamp body 4, an LED lamp bead 3, a light-emitting part 2 in the form of a cover, and a driver 7 including an AC drive power supply and a lamp body drive system. The light-emitting part 2 is circular , formed by coating a long afterglow luminescent material layer on the substrate. The long afterglow material used is suitable for the selection of LED lamp beads, and can be excited by the light emitted by at least part of the LED lamp beads. Eight blade-shaped through holes 1 are connected to the center of the luminous element 2 with a fixed column 8. The luminous element is connected to the driver 1 through the fixed column 8, and the components of the lamp are inserted into one body. The through hole 1 constitutes a The transparent part of the light-emitting element 2 and the part where the long afterglow luminescent material layer is formed on the substrate constitute the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com