Silencing machine cabinet of high-speed centrifugal-type fan

A high-speed centrifugal and fan technology, used in machines/engines, mechanical equipment, non-variable-capacity pumps, etc., can solve the problems of a single sound-absorbing material, affecting physical and mental health, and living troubles for residents, so as to improve sound insulation and noise reduction. ability, reduce aerodynamic noise, and enhance the effect of sound absorption and sound insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

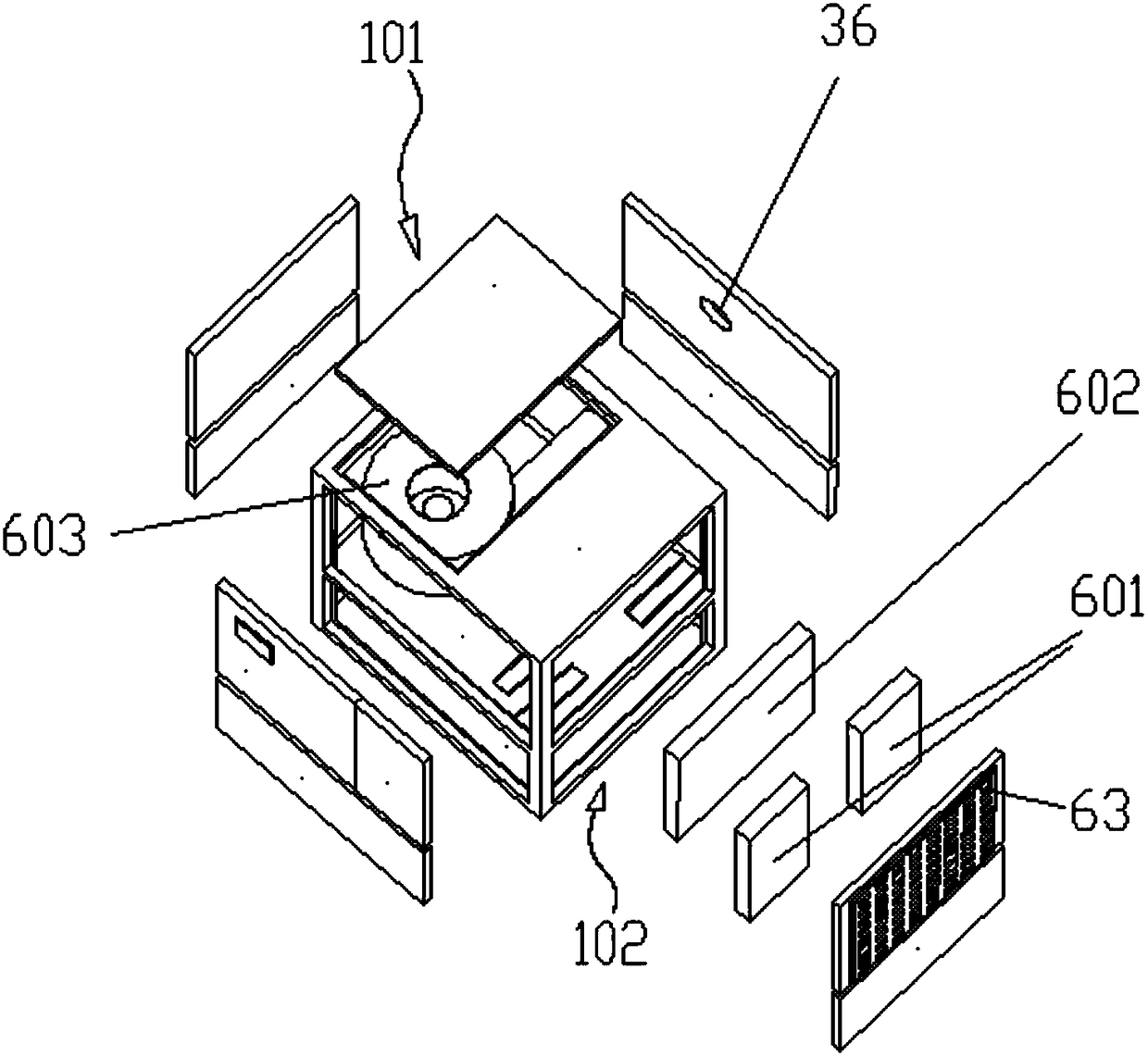

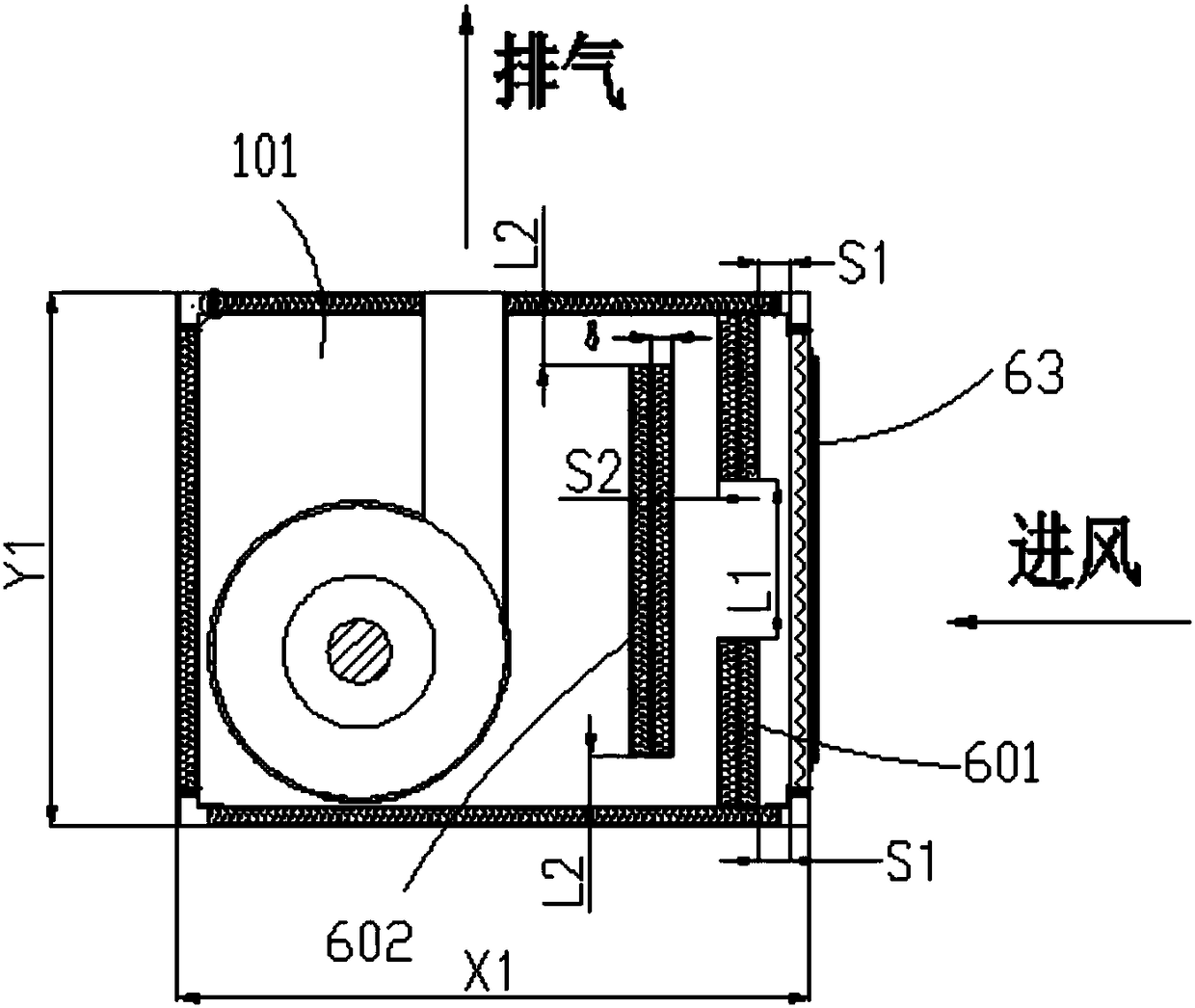

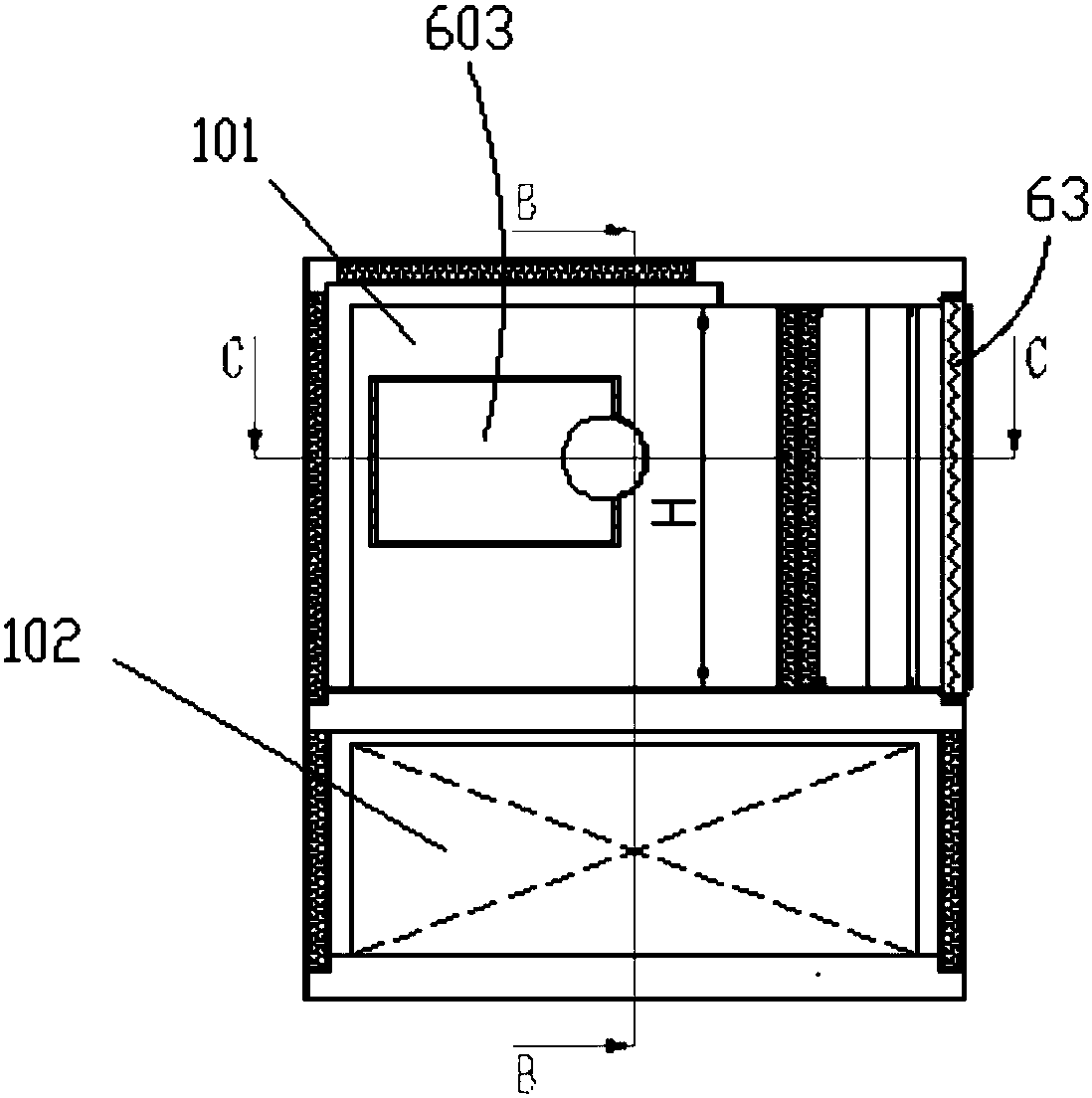

[0021] Such as Figure 1 to Figure 4 , the present invention discloses a high-speed centrifugal fan noise reduction cabinet, including a main cabinet 101, an electric control cabinet 102, an inlet filter 63 and a main machine 603, the main cabinet 101 and the electric control cabinet 102 are arranged in layers, and the main machine 603 is fixed on In the main cabinet 101, the inlet filter 63 is arranged on the outer wall of the main cabinet 101, and the outer wall of the main cabinet 101 is provided with an exhaust port 36, and also includes a small anechoic plate 601 and a large anechoic plate 602, and the large anechoic plate 602 is fixedly connected in the main cabinet 101, and the large sound-absorbing plate 602 and the inlet filter 63 are arranged parallel to each other, and a first gap is formed between the two ends of the large sound-absorbing plate 602 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com