Connecting mechanism capable of adjusting casing installation direction

A technology of installation direction and connection mechanism, which is applied in the direction of machines/engines, parts of pumping devices for elastic fluids, mechanical equipment, etc., and can solve the problems that the integrated structure cannot adjust the installation direction of the casing, is not beautiful, and has high cost , to achieve the effect of convenient and quick installation and adjustment, improved adaptability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

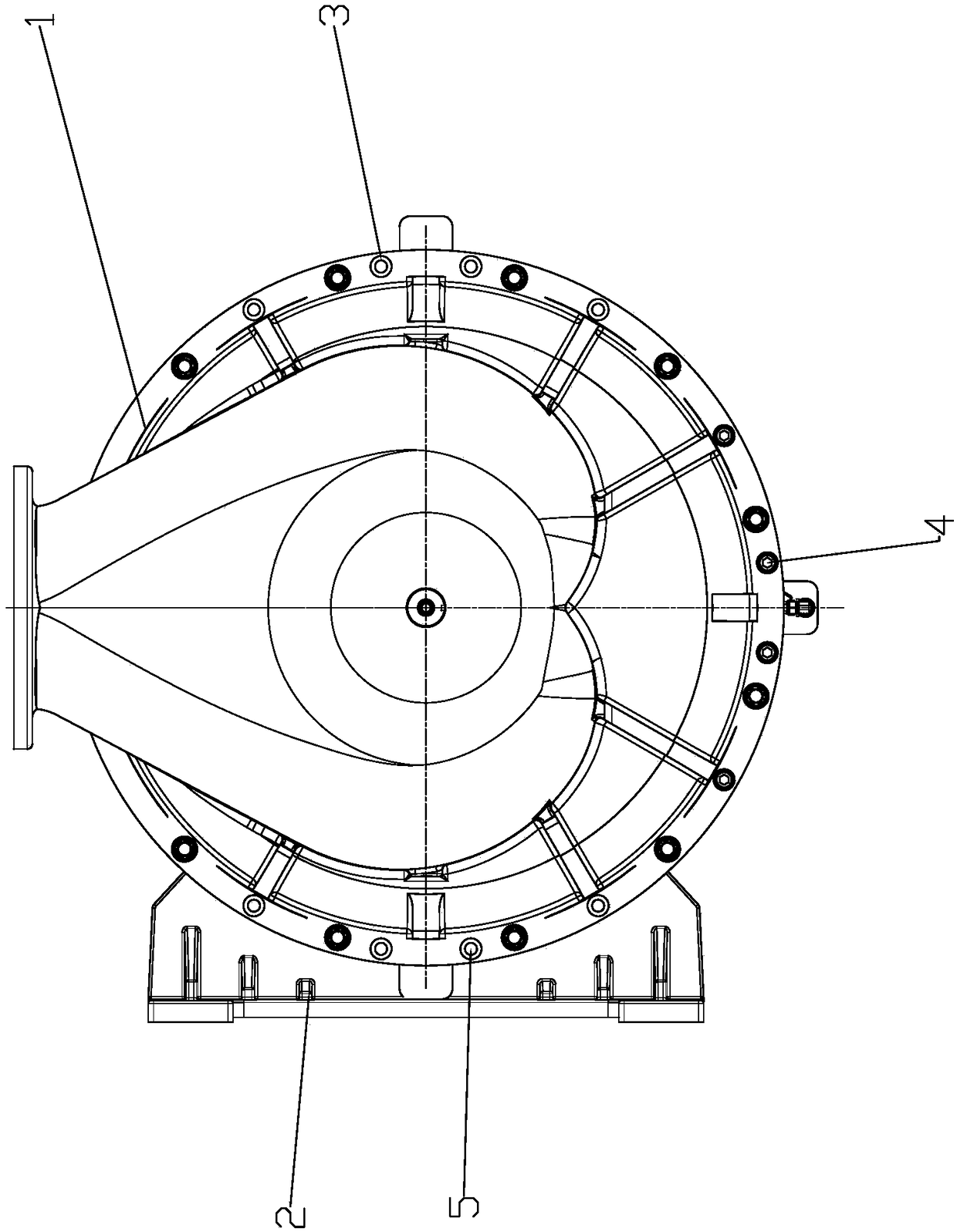

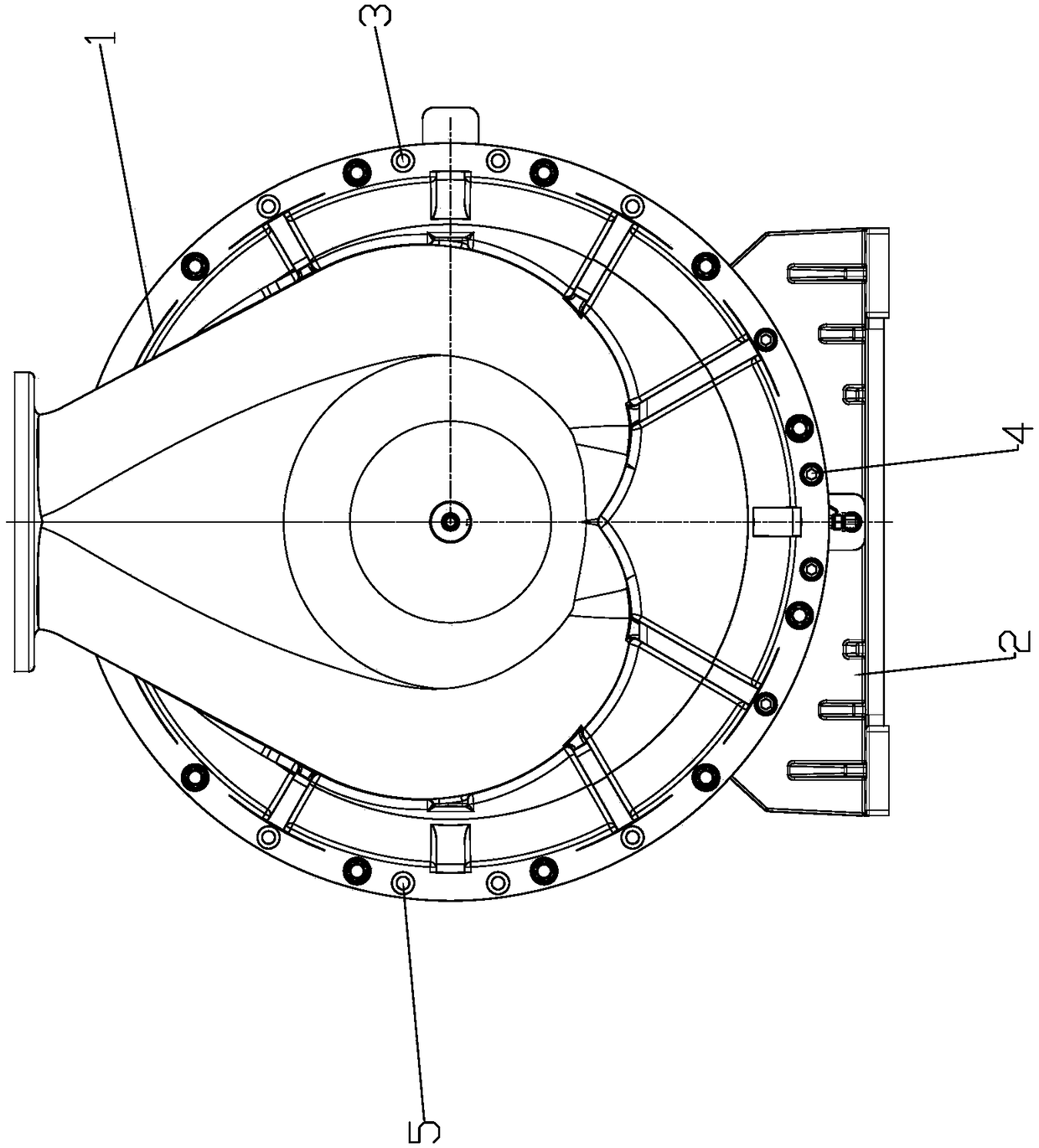

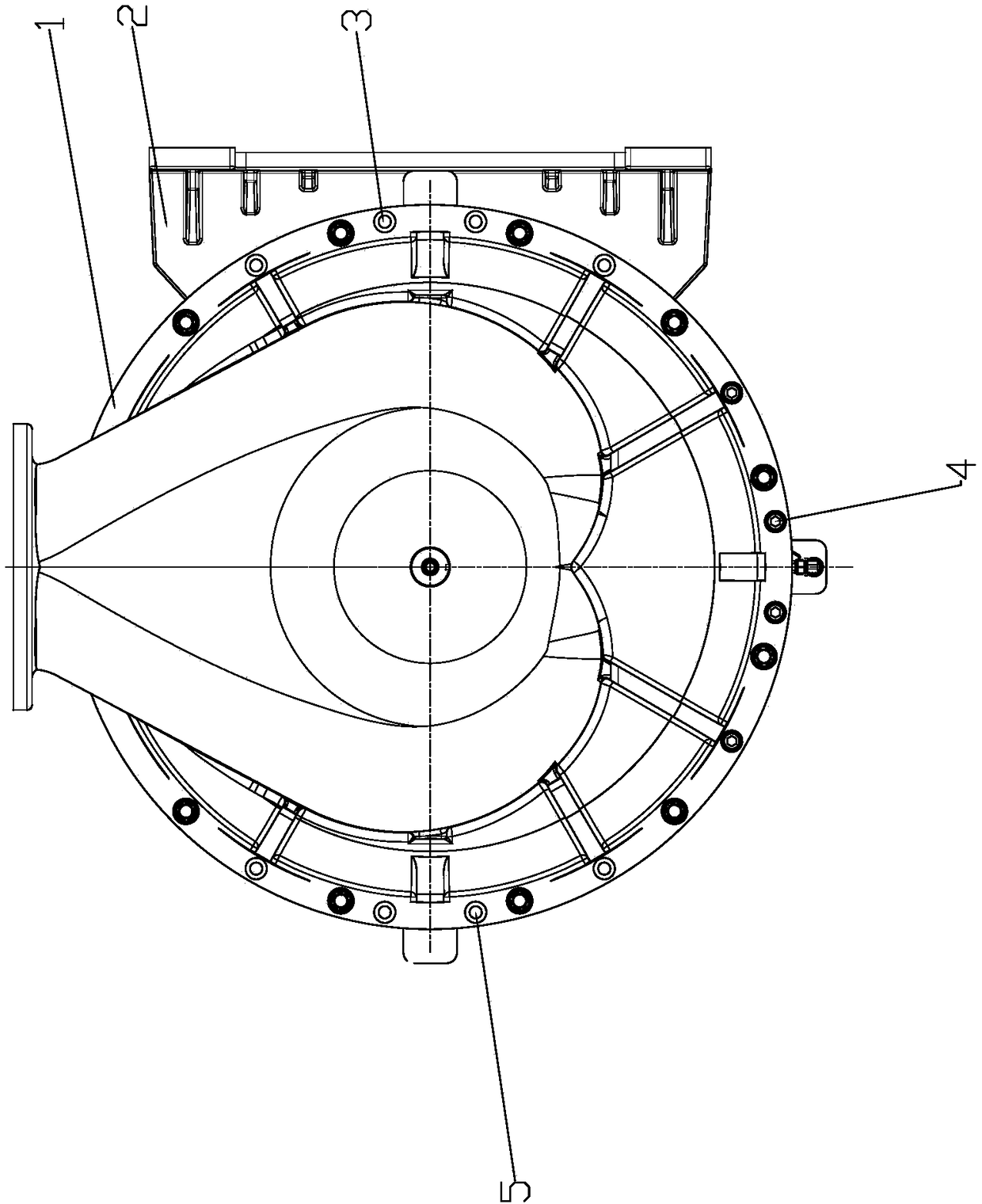

[0016] Such as Figure 1~3 As shown, the present invention mainly includes a centrifugal fan inlet and exhaust casing 1 and a base bracket 2, and the right side, the bottom and the left side of the centrifugal fan inlet and exhaust casing 1 are respectively provided with a first bracket mounting hole group and a second bracket mounting hole group. The hole group and the third bracket installation hole group, the first bracket installation hole group, the second bracket installation hole group and the third bracket installation hole group are evenly distributed along the same circumferential direction.

[0017] According to the difference in the angle position of the docking air pipe during installation, the base bracket 2 is connected and locked to the first bracket installation hole group or the second bracket installation hole group or the third brac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com