Integrated fabricated heat preservation external wall

A thermal insulation exterior wall, prefabricated technology, applied in thermal insulation, building thermal insulation materials, building components, etc., can solve the problems of low thermal insulation performance, poor moisture resistance of thermal insulation external walls, multiple joints, etc., so as to improve thermal insulation performance and reduce joint construction. Seams, the effect of reducing heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

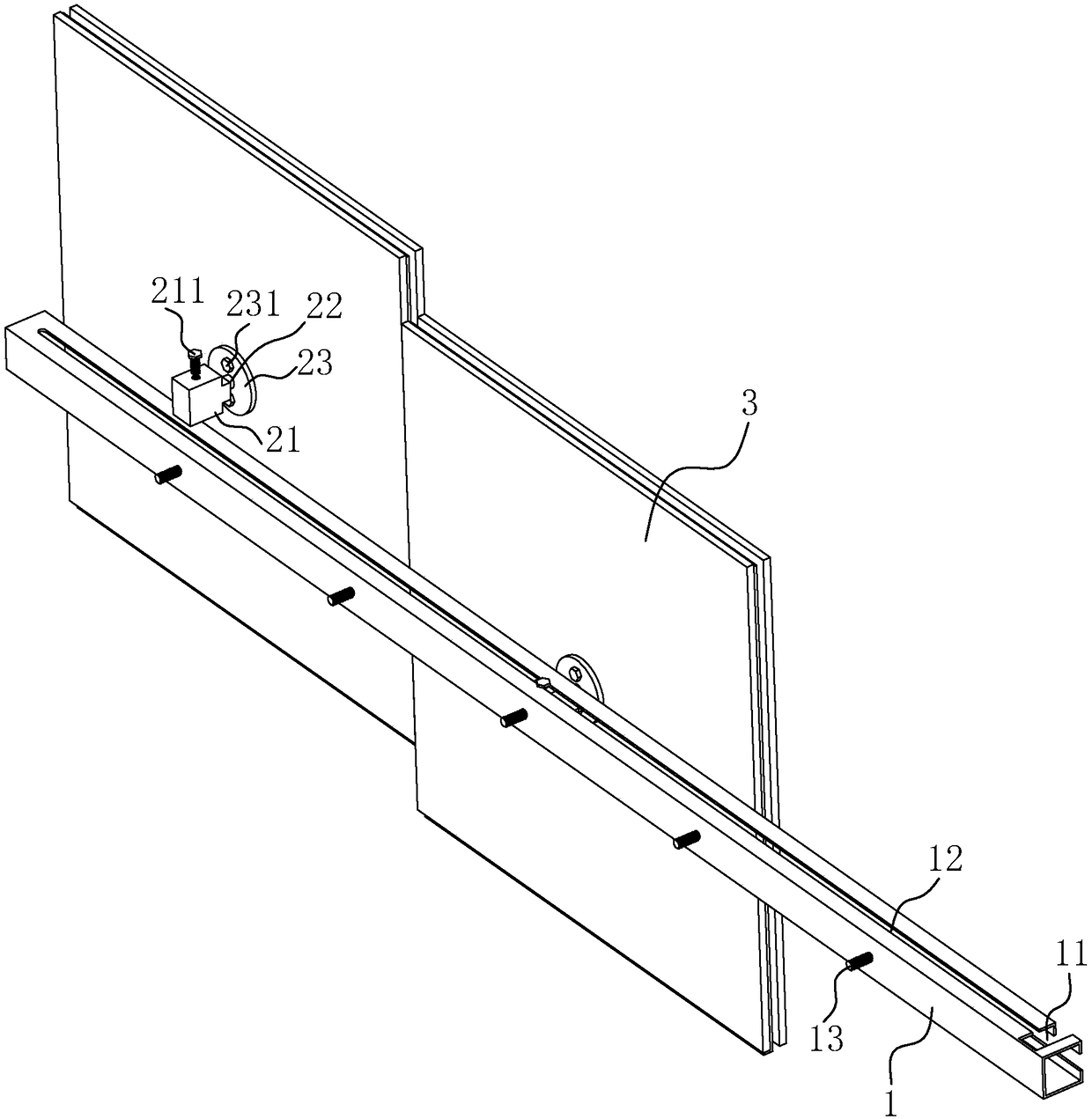

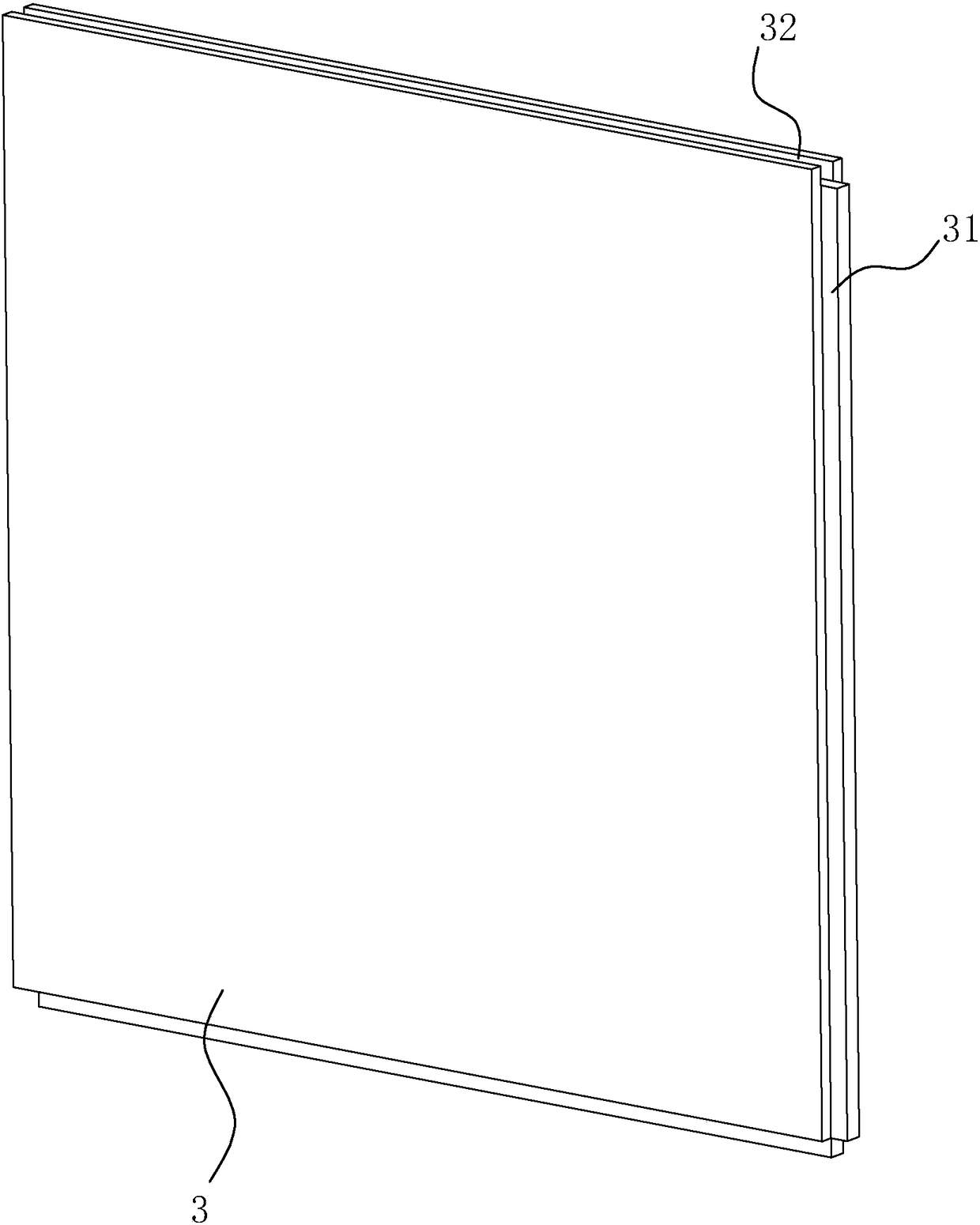

[0038] An integrated assembly type thermal insulation exterior wall, such as figure 1 with figure 2 As shown, it includes several channel steels 1 arranged horizontally, and the channel steels 1 can be fixed to the wall by means of expansion bolts 13. A first wall panel 2 and a second wall panel 3 are installed on the channel steel 1. The first wall panel 2 is dedicated to the installation of thermal insulation exterior walls in windows, balconies and other locations. Due to the complex size and shape of windows, balconies and other structures, under normal circumstances, the thermal insulation wall needs to be spliced with multiple pieces to cover the entire structure. There are many splicing joints, which makes the thermal insulation wall at windows and balconies poor moisture resistance and thermal insulation performance Low, the first wall panel 2 of the present invention is integrally manufactured and shaped according to the specific window or balcony structure, effecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com