cargo unloading device

A technology for unloading devices and goods, applied in the direction of lifting devices, etc., can solve the problems of poor operation, small gaps in the goods, and inability to grip the goods, and achieve the effect of simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below by means of specific embodiments:

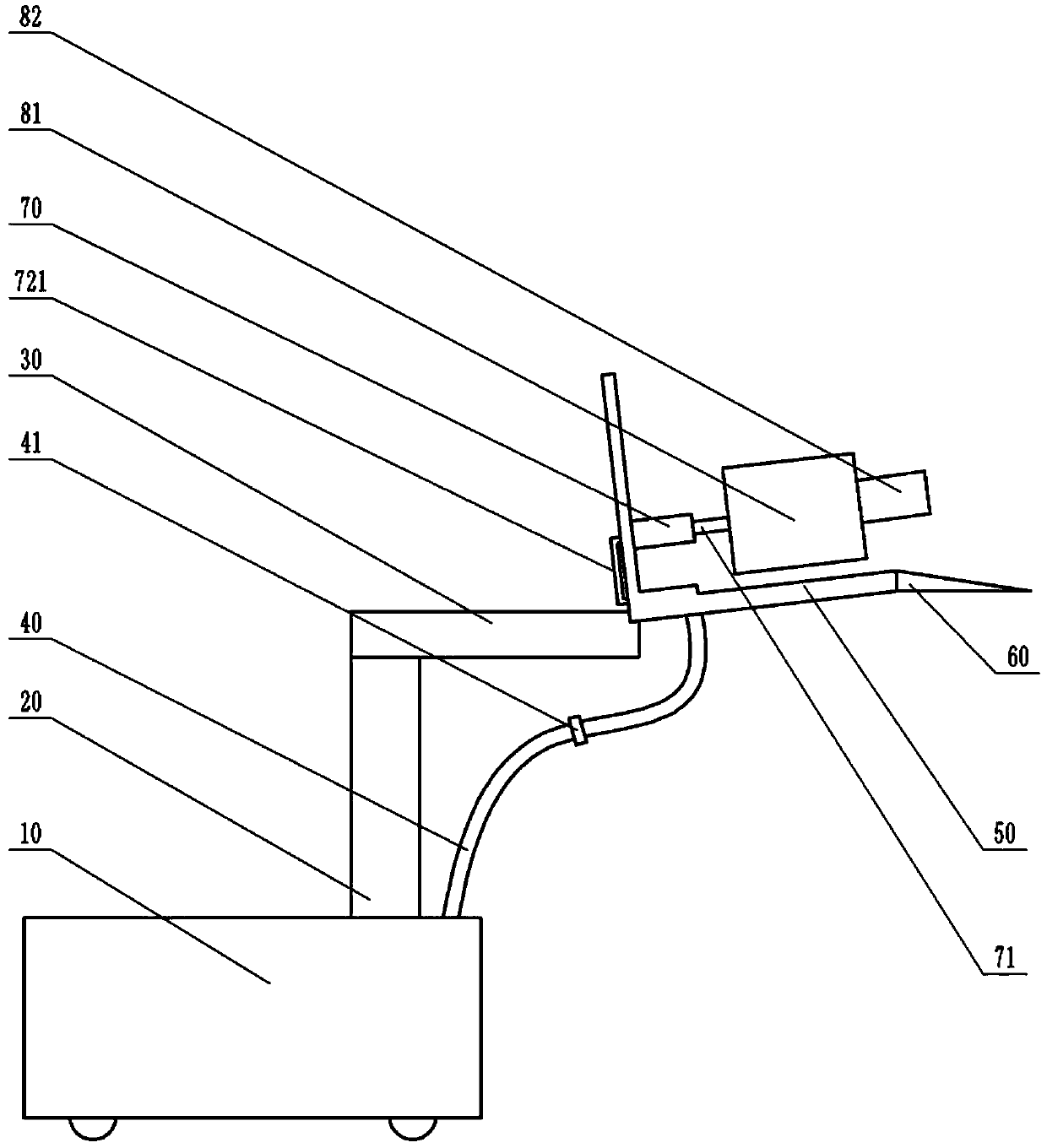

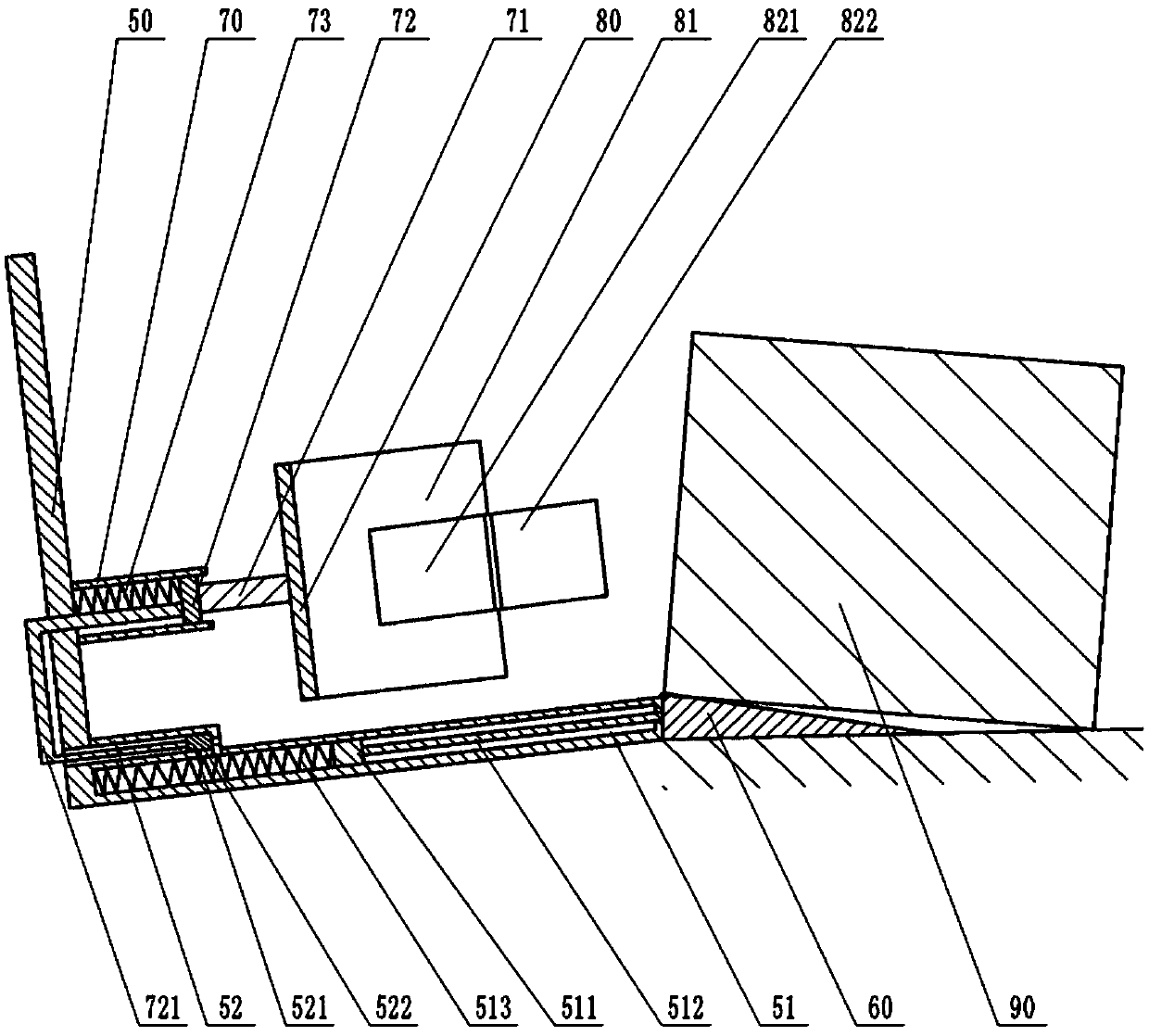

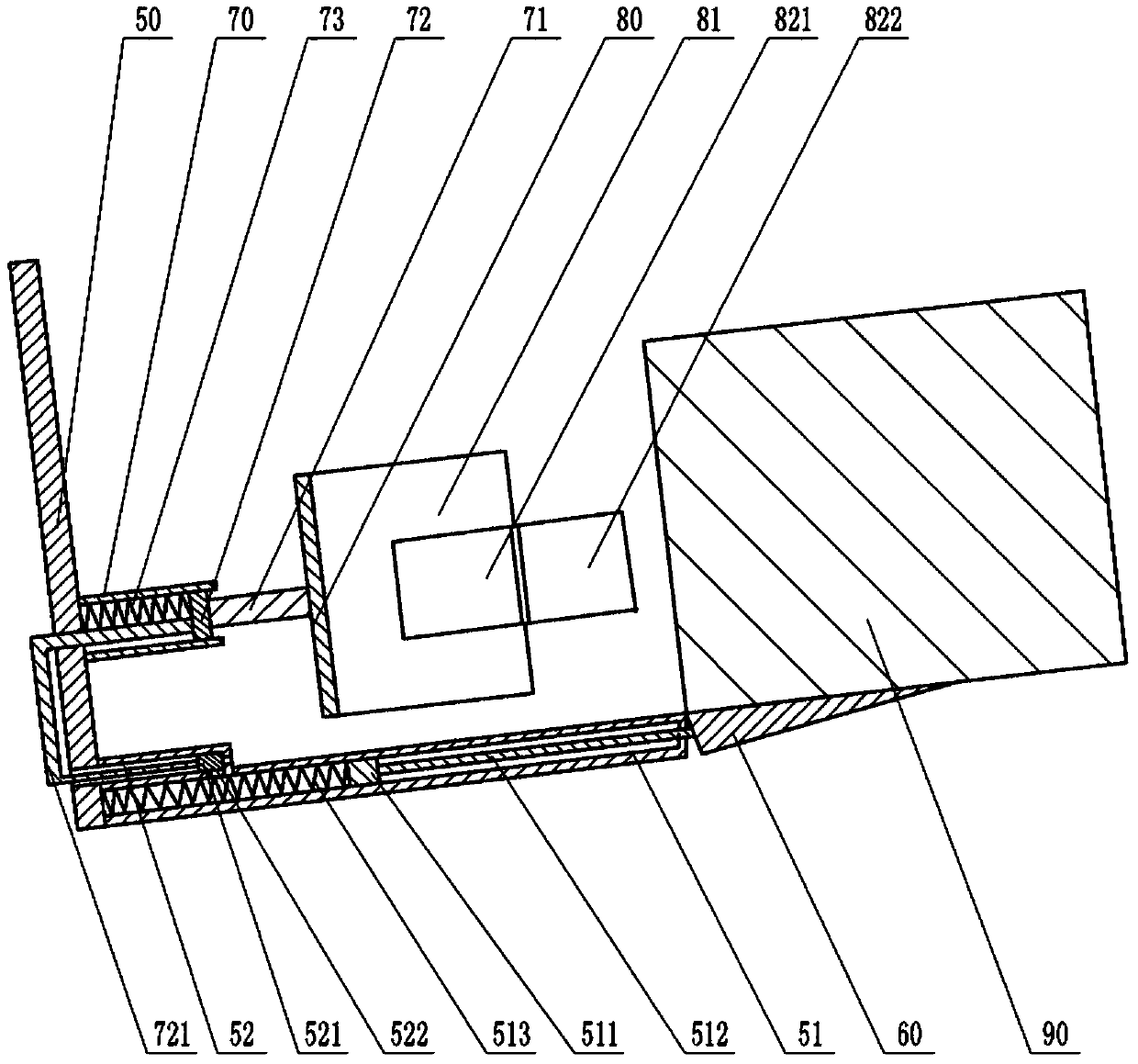

[0022] Instructions attached Figures 1 to 6 The reference signs in include: car body 10, first hydraulic cylinder 20, second hydraulic cylinder 30, air pipe 40, check valve 41, placement platform 50, cavity 51, piston 511, push rod 512, extension spring 513, Sleeve 52, plug 521, exhaust hole 522, push block 60, annular tube 70, push column 71, plunger 72, connecting rod 721, spring 73, support plate 80, extension plate 81, clamping plate 82, inner Plate 821 , outer plate 822 , support spring 83 , cargo 90 .

[0023] like figure 1 As shown, the cargo unloading device includes a car body 10, a lifting unit, a telescopic unit, a clamping unit and an inflatable unit fixed on the car body 10. In this embodiment, the inflatable unit is an air compressor. The lifting unit is the first hydraulic cylinder 20, the telescopic unit is the second hydraulic cylinder 30, the first h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com