Draining stirring paddle

A stirring paddle and flow-through technology, which is applied in the field of stirring paddles, can solve the problems of low stirring efficiency, achieve high stirring efficiency, improve mixing effect, and shorten mixing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

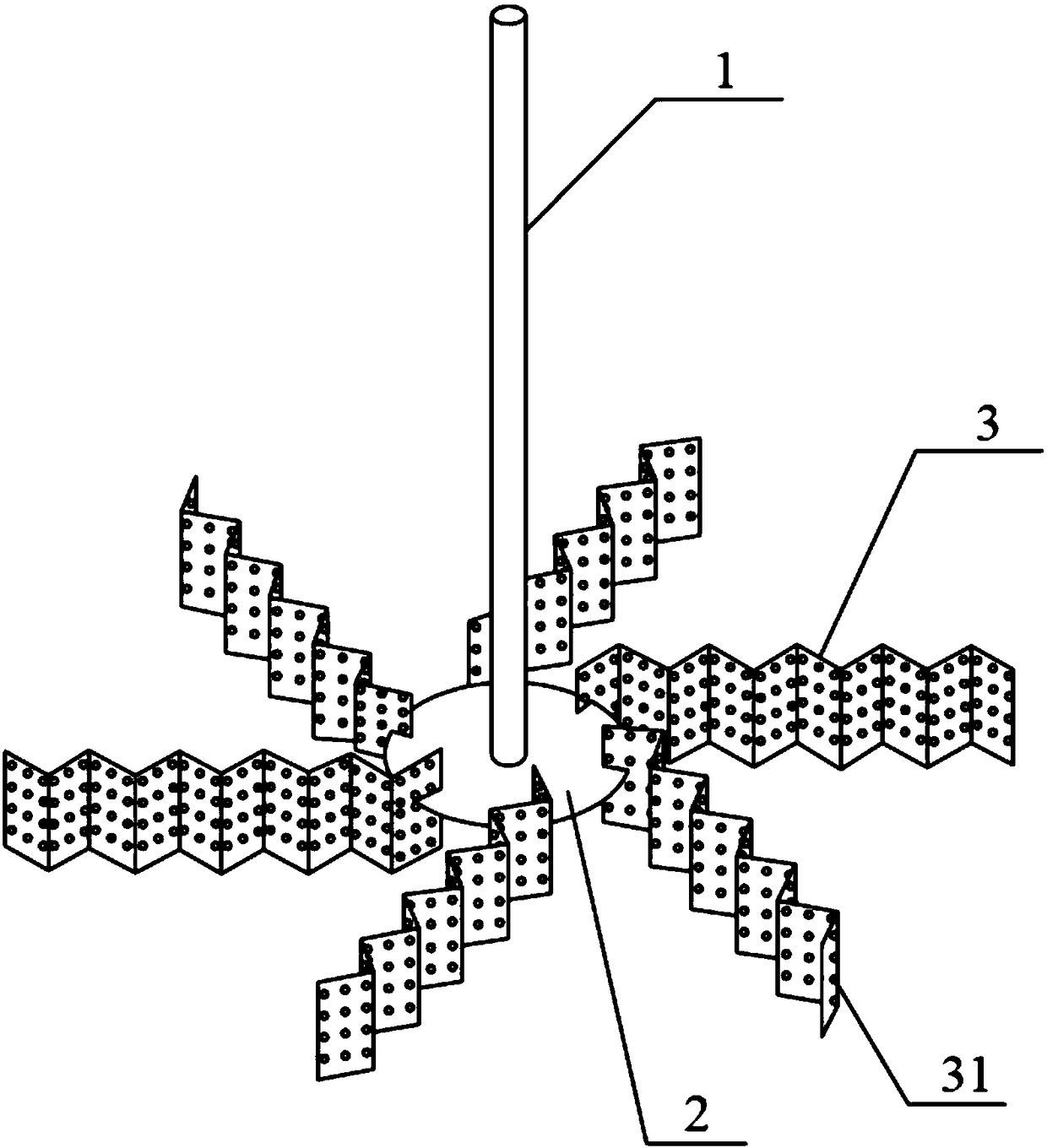

[0033] The stirred tank (not shown in the figure) reactor has a diameter of 240 mm and a height of 300 mm. Four baffles are installed away from the wall, and the baffles are 300 mm high and 20 mm wide. The top view of the through-flow paddle blade 3 is a broken line (ie figure 2 ), the angle α between two adjacent broken lines is 45°, the diameter of the through-flow hole 31 is 5 mm, and the center-to-center distance between two adjacent through-flow holes 31 is 10 mm. The paddle diameter of the paddle 3 is 80 mm, the paddle height is 24 mm, the number of blades of the paddle 3 is 6, and the height of the paddle 3 from the bottom is 80 mm.

[0034] Figure 5 It is a structural schematic diagram of the through-flow stirring paddle in the prior art, and its difference from the through-flow stirring paddle provided by the present invention is that the shape of the paddle 3 in the present invention is a wave-shaped structure, while the through-flow stirring paddle in the prior a...

Embodiment 2

[0040] Other conditions are the same as in Example 1, except that the diameter of the through-flow hole 31 is 6mm. The results of the comparative experiment are shown in Table 2.

[0041] Table 2 Performance comparison between the existing through-flow propeller and the high-efficiency through-flow propeller of the present invention

[0042]

[0043] It can be seen from the experimental results in Table 2 that at the same stirring speed, the mixing time of the through-flow stirring blade of the present invention is shortened by 12.75% compared with the existing through-flow stirring blade.

Embodiment 3

[0045] Other conditions are the same as in Example 1, except that the shape of the through-flow stirring paddle 3 is arc-shaped, and the results of the comparative experiment are shown in Table 3.

[0046] Table 3 Performance comparison between the existing through-flow paddle and the high-efficiency through-flow paddle of the present invention

[0047]

[0048] It can be seen from the experimental results in Table 3 that at the same stirring speed, the mixing time of the through-flow stirring blade of the present invention is shortened by 11.82% compared with the existing through-flow stirring blade.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com