Soybean milk machine

A soymilk machine and cup body technology, applied in the field of soymilk machine, can solve the problems of strong sense of heaviness, unattractive appearance, heavy overall weight of the machine head, etc., achieve reduction in the thickness and weight of the machine head, facilitate operation and observation, and improve portability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

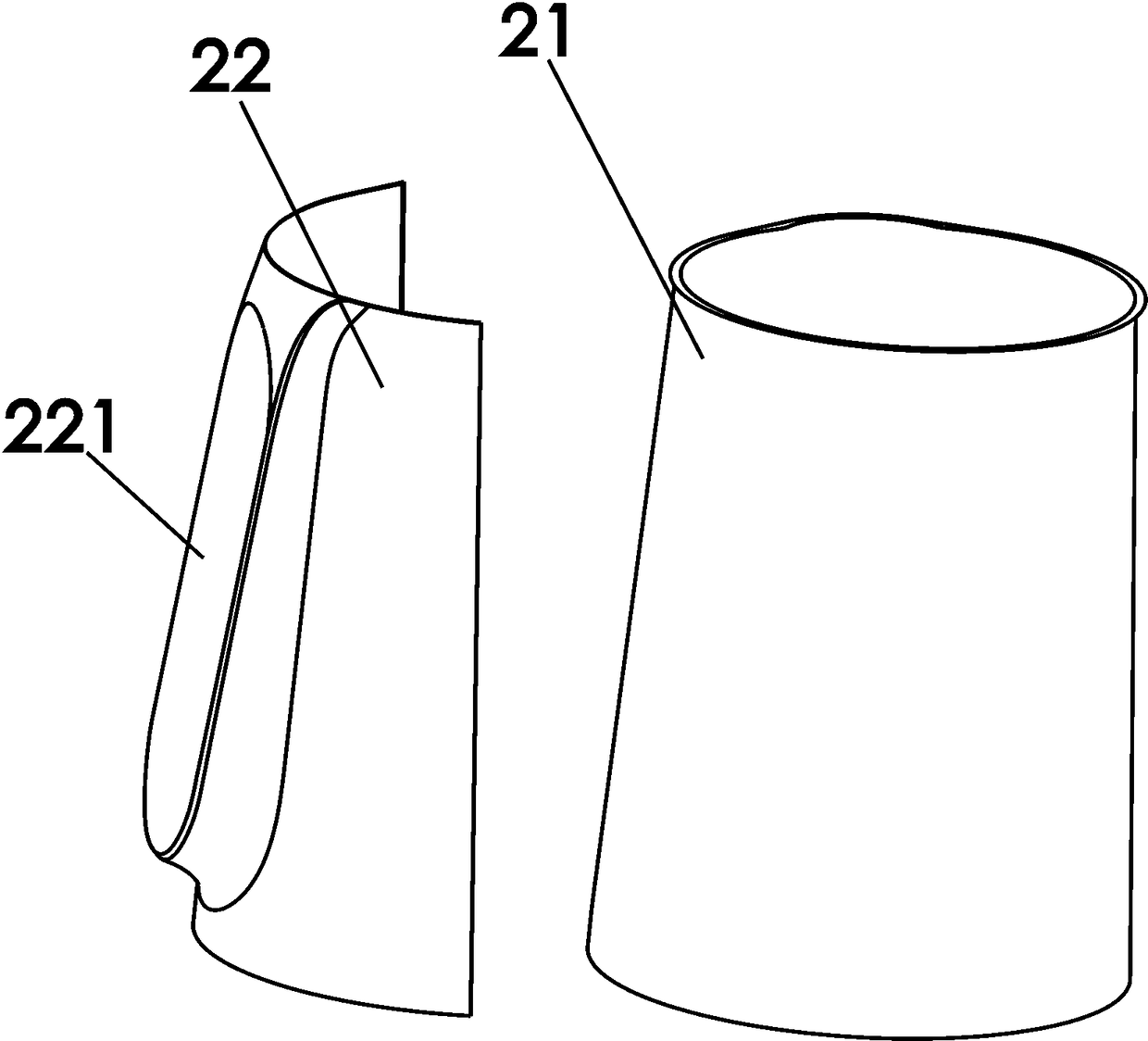

[0028] Such as figure 1 , figure 2 Shown is a schematic structural diagram of the first embodiment of the present invention. A soybean milk machine, comprising a machine head 1 and a cup body 2, the machine head 1 is installed on the cup body 2, and the cup body 2 includes a cup body base 21 and a cup body shell 22 arranged outside the cup body base 21 , the cup housing 22 is provided with an outwardly protruding interface interaction part, an interface interaction area 221 is formed on the outside of the interface interaction part, and an accommodating cavity for accommodating a circuit board is formed on the inside of the interface interaction part (located at the interface interaction area, not marked in the figure).

[0029] In this embodiment, the cup body base 21 is a single-layer metal cup body, the cup body shell 22 is an interface mounting plate with a plate-like structure fixed on the outside of the metal cup body, and the interface interaction area 221 is located...

Embodiment 2

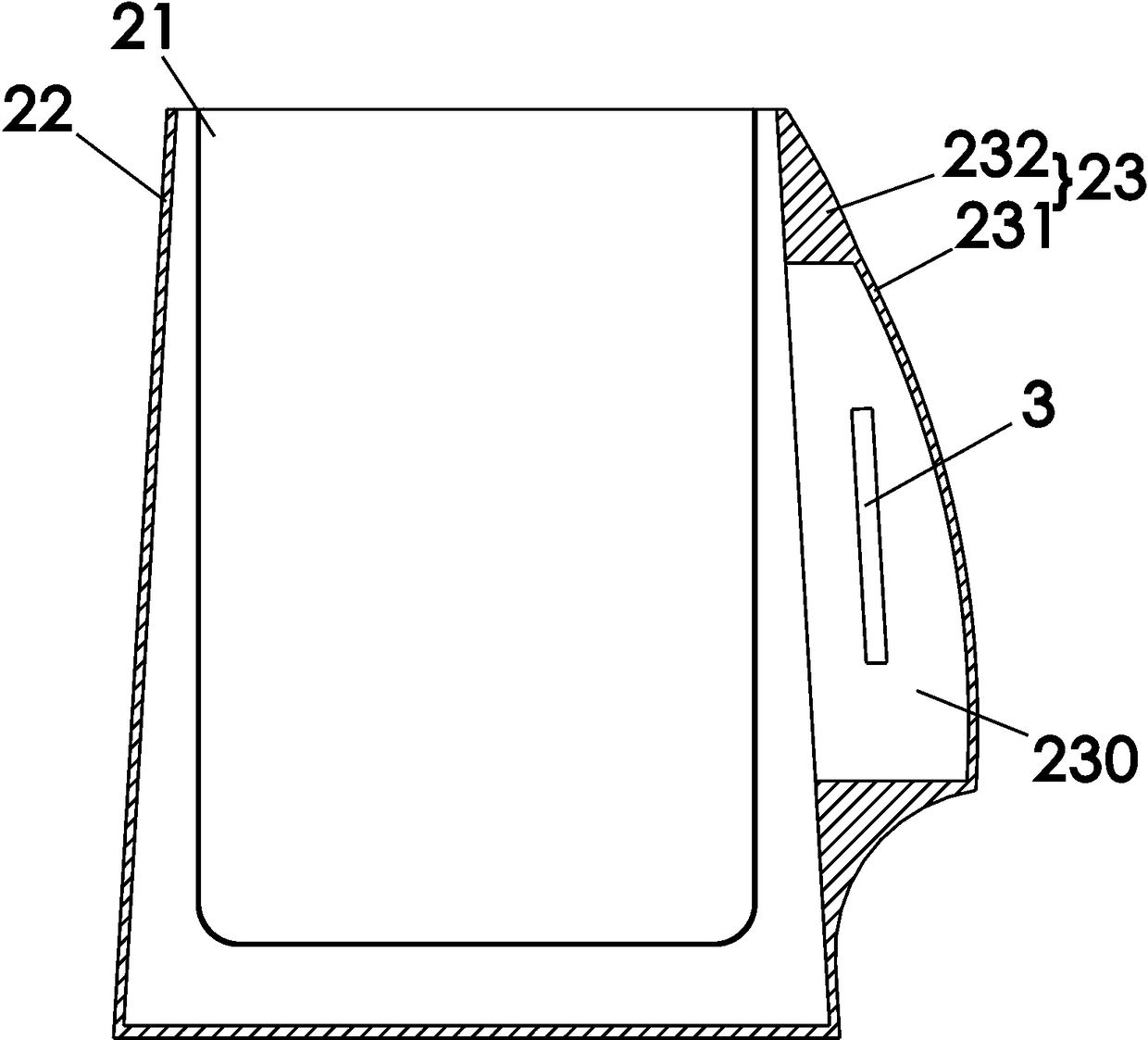

[0033] Such as image 3 , Figure 4 Shown is a schematic structural diagram of the second embodiment of the present invention. The difference between this embodiment and Embodiment 1 is that in this embodiment, the cup base 21 is a metal cup, and the cup shell 22 is a barrel-shaped cup shell set on the outside of the metal cup. The interface interaction part 23 includes an interface interaction board 231 and a raised seat 232 connected with the interface interaction board 231 , the interface interaction area is located on the interface interaction board 231 , wherein the interface interaction board 231 and the raised seat 232 are integrally injection molded. And the circuit board 3 is disposed in the receiving cavity 230 formed by the interface interaction board 231 and the raised seat 232 .

[0034] For this embodiment, of course, the interface interaction board can also be a split structure with the raised seat, for example: the interface interactive board can be fixed on ...

Embodiment 3

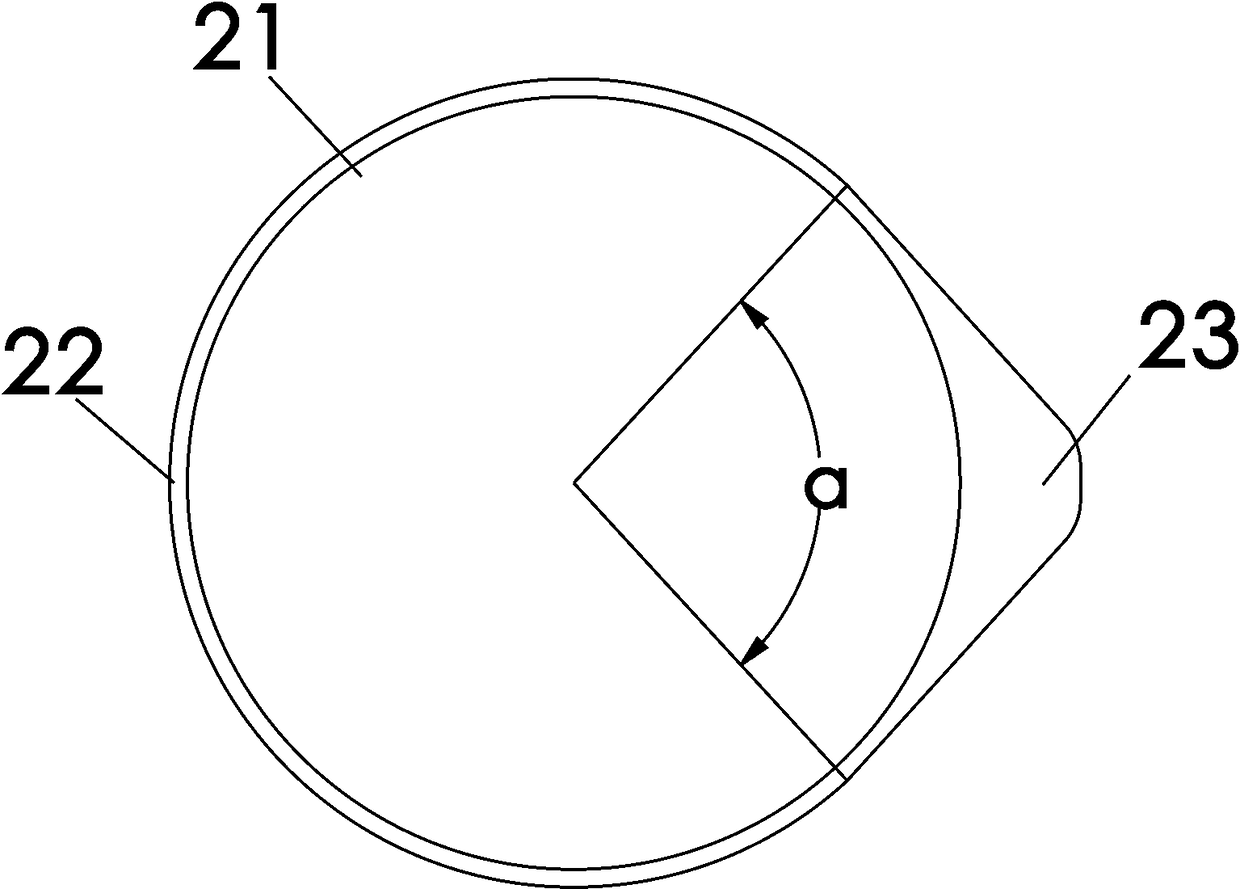

[0038] Such as Figure 5 , Figure 6 Shown is a schematic structural view of the third embodiment of the present invention. The difference between this embodiment and the second embodiment is that: in this embodiment, the raised seat 232 is set through the outer shell of the cup body, and the outer edge of the raised seat 232 is provided with a through hole 2320, and the interface interaction plate 231 is fixed on the through hole. mouth 2320, and seal the through opening 2320, and an isolation plate 4 is also arranged in the interlayer between the metal cup body and the interface interaction part, and the isolation plate 4 is surrounded by the accommodating cavity 230 to form a seal for the circuit board 3 cavity.

[0039]In this embodiment, the bulging height of the interface interaction part is C, wherein C is required to be at least greater than 10 mm. Because, for this embodiment, the inner side of the interface interaction part is to form the accommodating cavity for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com