Vamp automatic steaming setting machine and vamp steaming setting method

A setting machine and steam setting technology, which is applied to shoe uppers, footwear, insoles, etc., can solve the problems of increasing labor costs, low efficiency, and unstable product quality of setting effects, and achieve good results, high efficiency, and elimination of uppers. The effect of internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to further explain the technical solution of the present invention, it will be described in detail below in conjunction with the accompanying drawings.

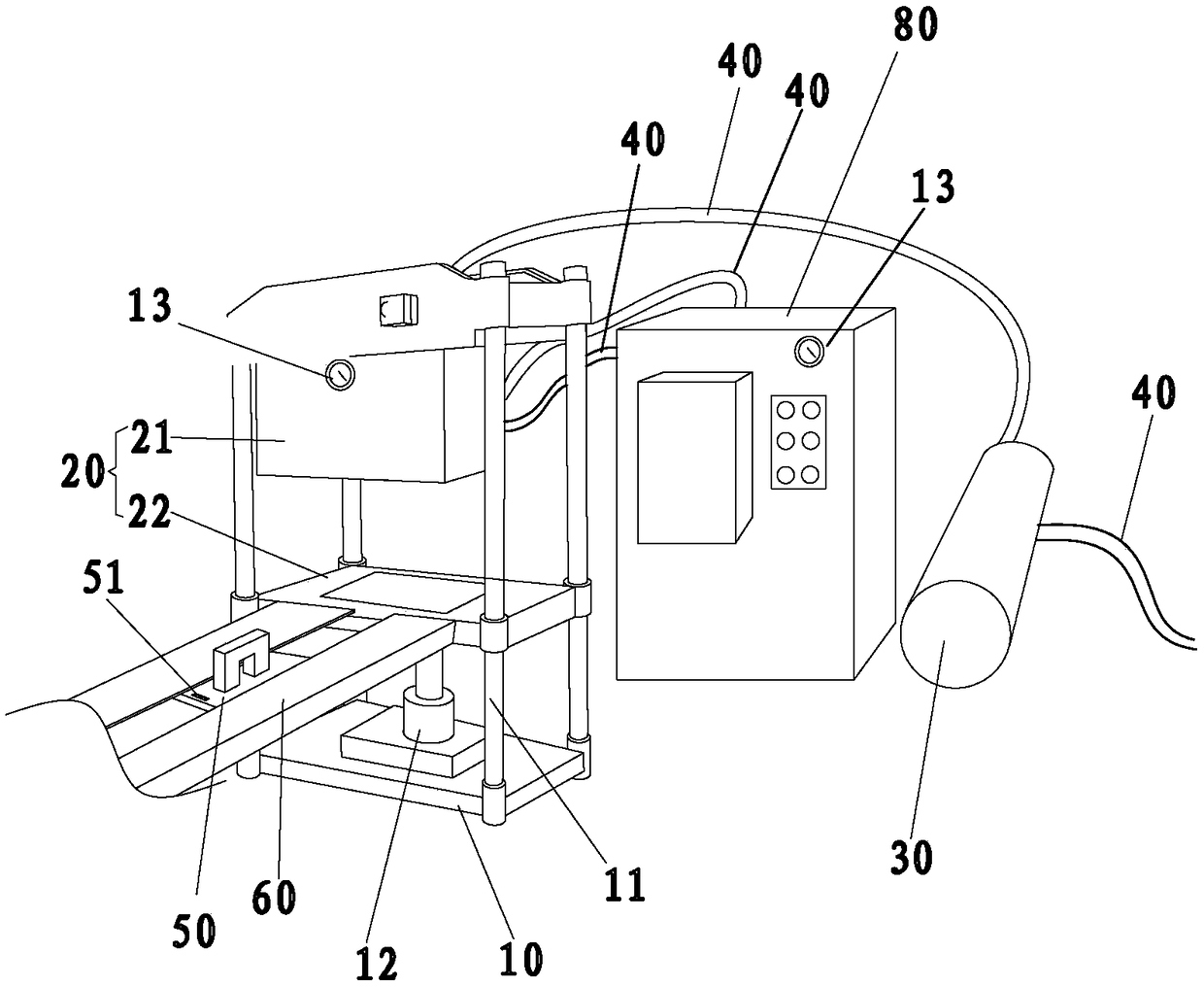

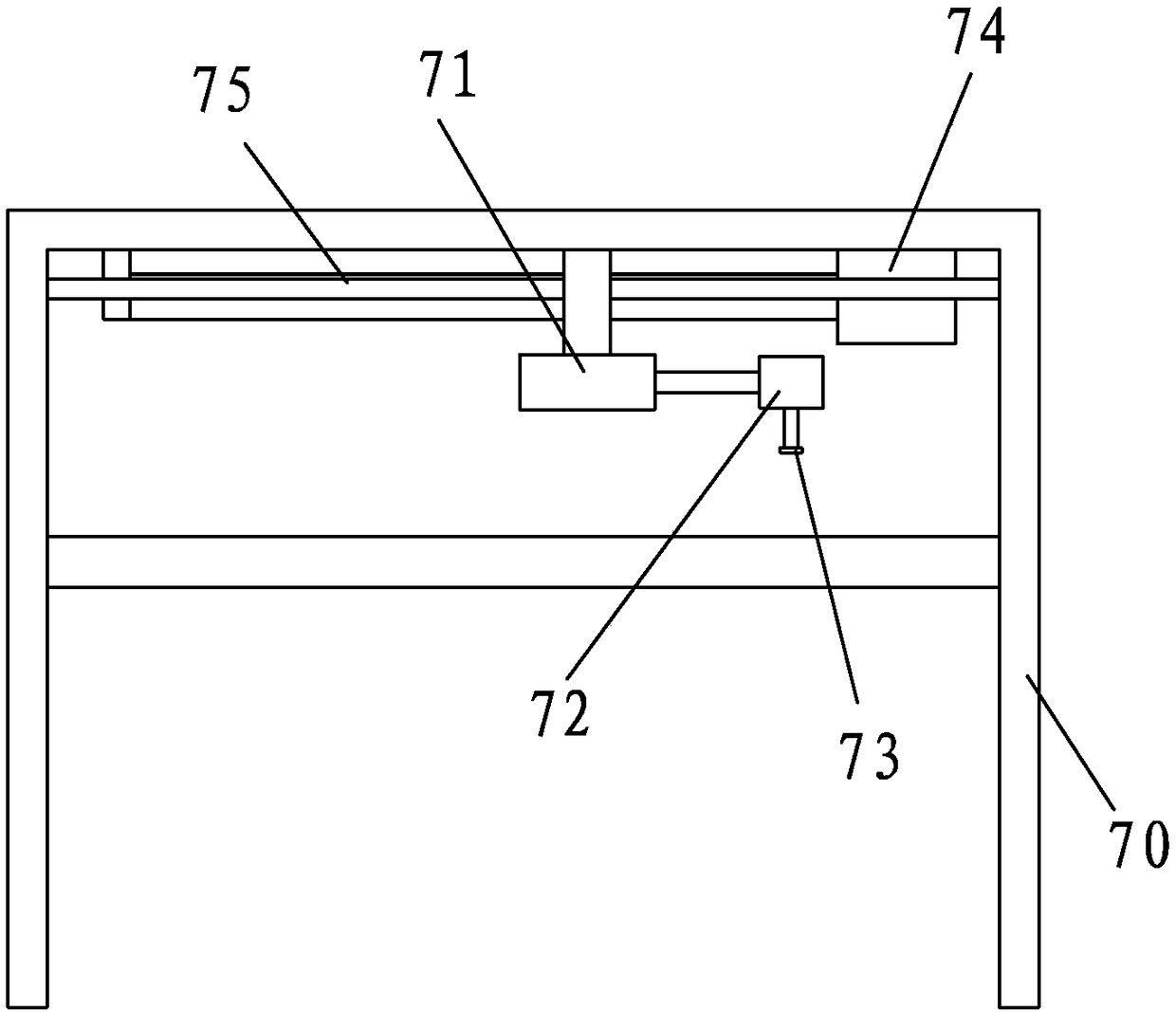

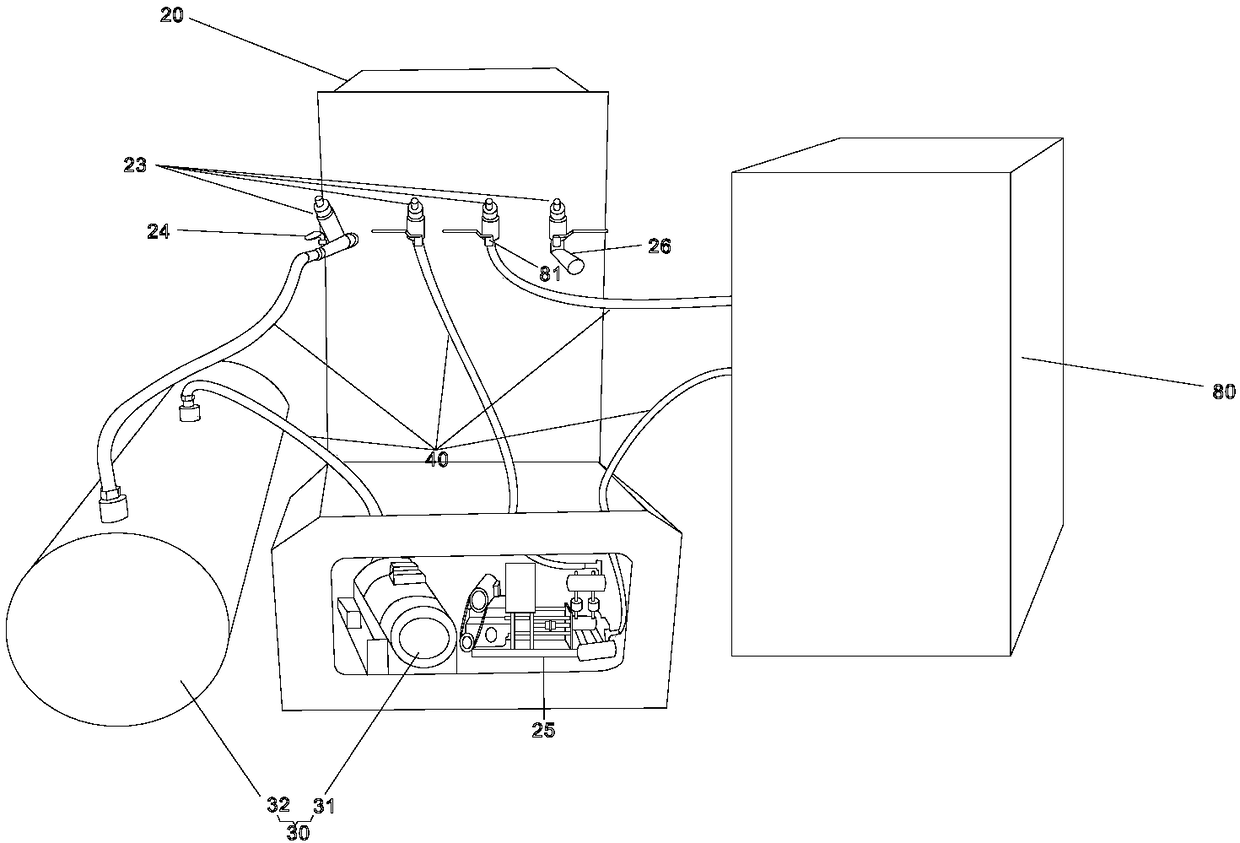

[0044] refer to figure 1 , figure 2 and image 3 , the upper automatic steaming and setting machine, including steaming and setting box 20, steam generating device 80, pressure gauge 13 for detecting steam pressure, air intake device 26, steam recovery machine 25 and vacuuming device 30, steam generating device The steam output port 81 of 80 is connected to the steam chamber of the steam-humidity setting box 20, and the steam pressure is preset through the corresponding pressure gauge 13 on the steam generating device 80. When the set standard is reached, the generated steam enters the steam chamber The injection pressure can reach 0.1MPa-0.5MPa, the output end of the air inlet device 26 is connected with the steam chamber, before the steam shaping box 20 is opened, air is sent into the steam chamber throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com