Self-adsorption flexible battery and preparation method thereof

A flexible battery, self-adsorption technology, applied in secondary battery manufacturing, batteries, climate sustainability, etc., to achieve the effects of less difficulty in industrialization, low preparation cost, and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

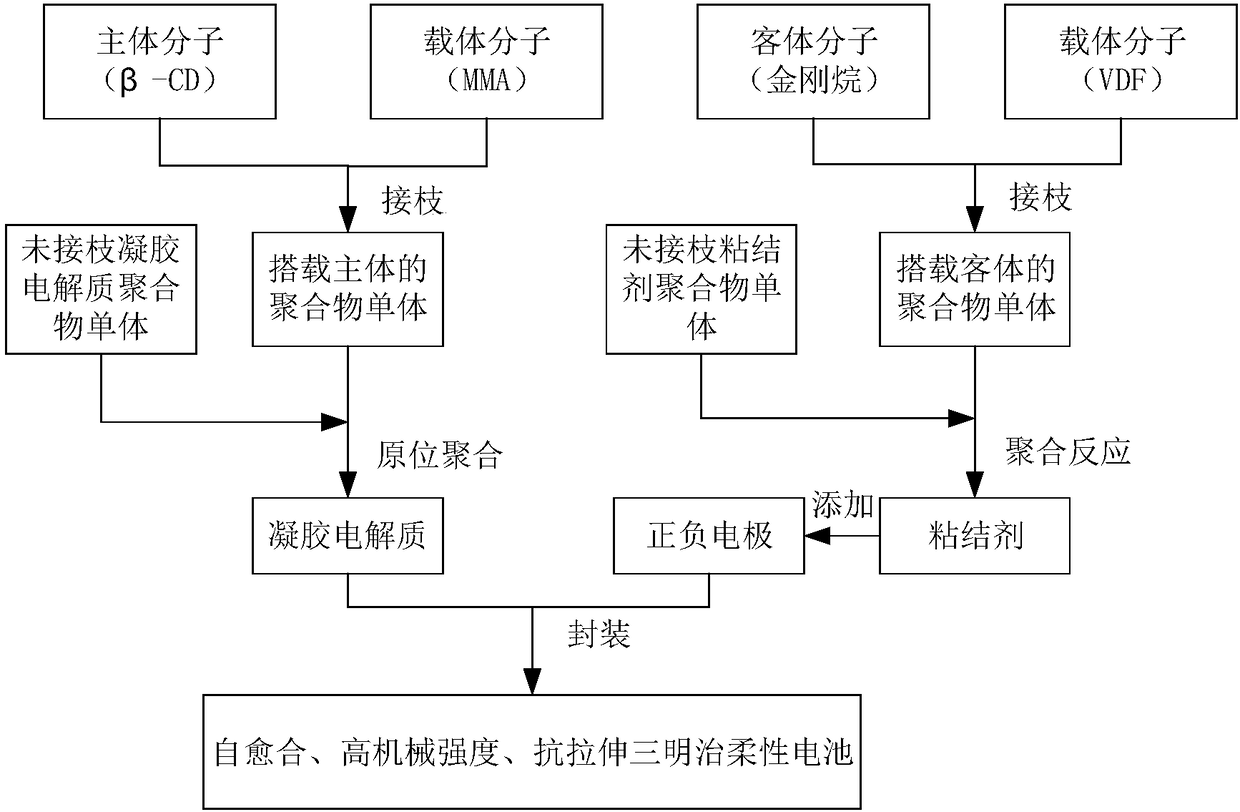

[0049] A method for preparing a self-absorbing flexible battery, comprising the following steps:

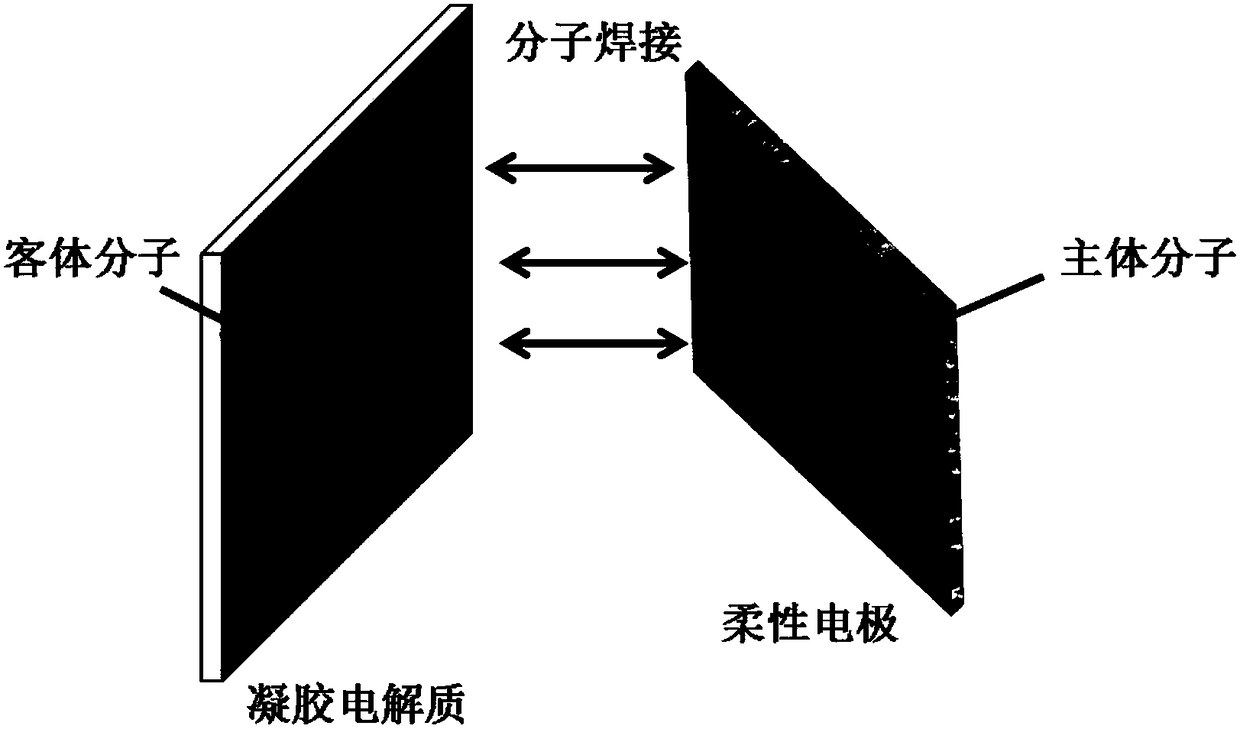

[0050] (1) The main body is cyclodextrin, and the guest is adamantane. Put the host in the initiator Na 2 S 2 o 8 Grafting to the gel electrolyte polymer monomer under the action to form a polymer monomer matrix carrying host molecules;

[0051] The gel electrolyte polymer monomer is methyl methacrylate. Step (1) The mass ratio of methyl methacrylate and cyclodextrin during the grafting reaction is 1:0.1; the amount of the initiator used in the grafting copolymerization reaction is 0.01 wt% of the total mass of the monomers.

[0052] (2) The prepared polymer monomer matrix carrying host molecules is in-situ polymerized with ungrafted acrylonitrile and methyl methacrylate to generate a gel electrolyte mixed with host molecules; ungrafted propylene The mass ratio of nitrile and methyl methacrylate to the polymer monomer matrix carrying host molecules is 1:0.3. Step (2) The po...

Embodiment 2

[0058] A method for preparing a self-absorbing flexible battery, comprising the following steps:

[0059] (1) wherein, the subject is cyclodextrin, and the guest is ferrocene; the subject cyclodextrin is grafted onto the gel electrolyte polymer monomer under the action of an initiator to form a polymer monomer matrix carrying the subject molecule;

[0060] Wherein the gel electrolyte polymer monomer is acrylonitrile. The chosen initiator is Na 2 S 2 o 8 and K 2 S 2 o 8 . Step (1) The mass ratio of the gel electrolyte gel polymer monomer to the main body is 1:5 during the grafting reaction; the amount of the initiator used in the graft copolymerization reaction is 5 wt% of the total mass of the monomers.

[0061] (2) Perform in-situ polymerization reaction between the prepared polymer monomer matrix carrying host molecules and ungrafted gel electrolyte polymer monomer methyl methacrylate to generate a gel electrolyte mixed with host molecules; step The mass ratio of the...

Embodiment 3

[0067]A method for preparing a self-absorbing flexible battery, comprising the following steps:

[0068] (1) wherein the subject is cyclodextrin, and the guest is adamantane; the subject cyclodextrin is grafted onto the gel electrolyte polymer monomer under the action of an initiator to form a polymer monomer matrix carrying the host molecule;

[0069] Wherein the gel electrolyte polymer monomer is hexafluoropropylene. The selected initiator is (NH 4 ) 2 S 2 o 8 / NaHSO 3 , (NH 4 ) 2 S 2 o 8 / Na 2 SO 3 、Na 2 S 2 o 8 / NaHSO 3 . Step (1) Gel Electrolyte The mass ratio of the gel polymer monomer to the main body is 1:2 during the graft reaction; the amount of the initiator used in the graft copolymerization reaction is 1 wt% of the total mass of the monomer.

[0070] (2) Carry out the in-situ polymerization reaction between the prepared polymer monomer matrix carrying the host molecule and the ungrafted gel electrolyte polymer monomer to generate a gel electrolyte ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com