A kind of calcium carbonate hollow microsphere and preparation method thereof

A calcium carbonate, hollow technology, applied in the direction of calcium carbonate/strontium/barium, etc., can solve the problems of material performance decline, unfavorable mass production, small specific surface area, etc., to increase specific surface area, improve migration ability, and increase specific surface area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

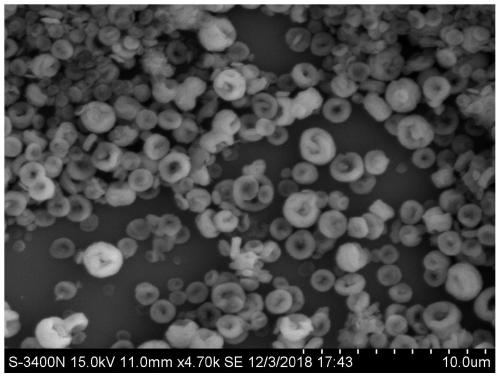

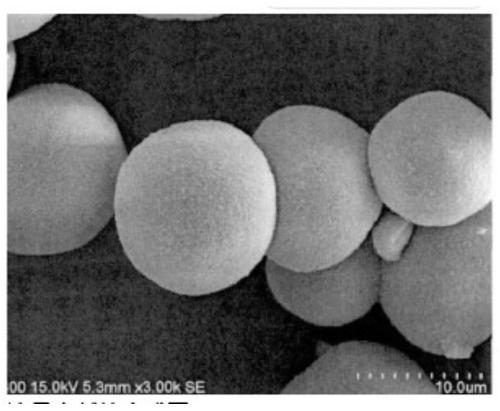

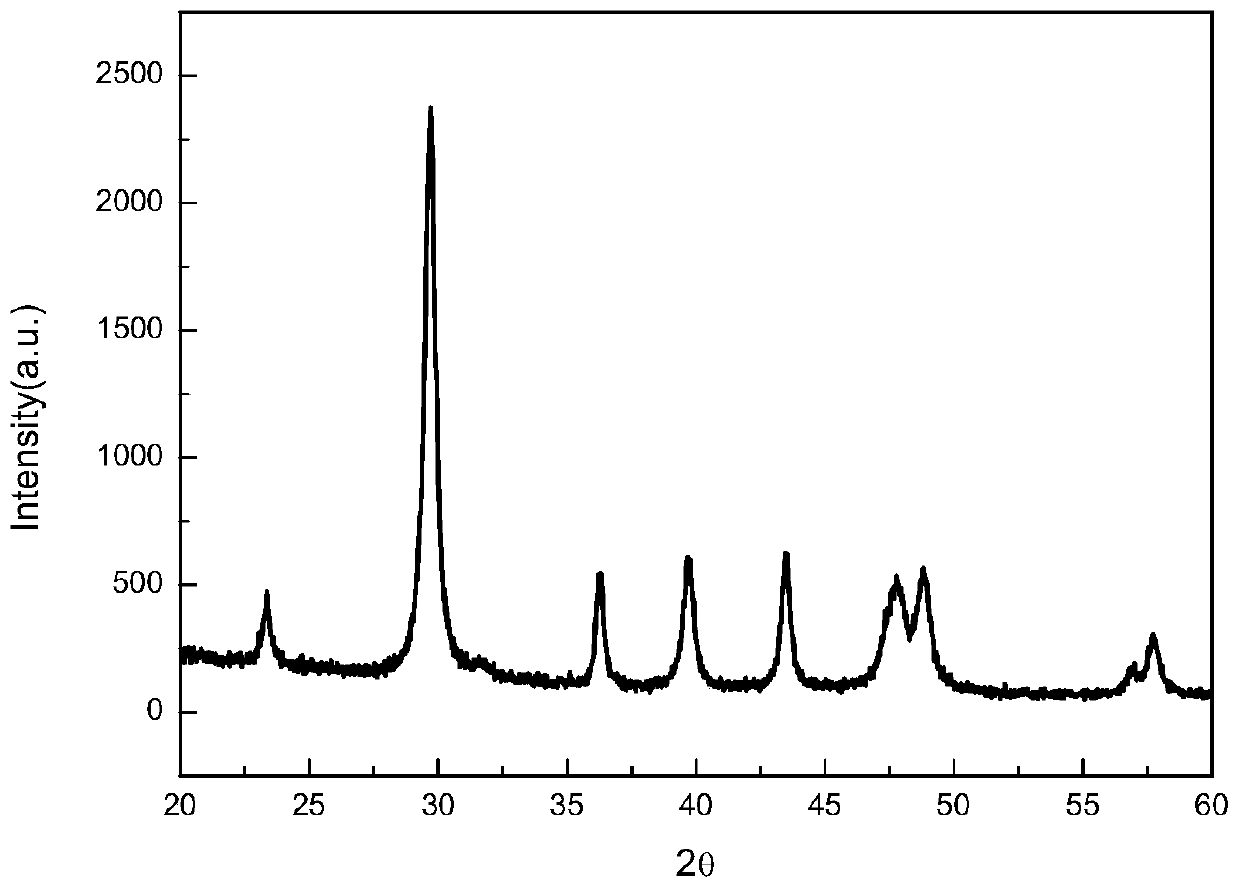

[0043] This embodiment provides a calcium carbonate hollow microsphere and a preparation method thereof, which specifically includes the following steps:

[0044] 1. Weigh 1.11g anhydrous calcium chloride and 1.06g anhydrous sodium carbonate and dissolve in 100mL deionized water;

[0045] 2. Weigh 0.3g of polyacrylic acid and dissolve it in 50mL of deionized water, divide it into two portions of 25mL each;

[0046] 3. Weigh 261 mg of sodium dodecylbenzene sulfonate and dissolve it in 50 mL of deionized water;

[0047] 4. Add 25mL of polyacrylic acid solution to the calcium chloride and sodium carbonate solutions, and stir for 30 minutes at a speed of 100-300r / min;

[0048] 5. Under vigorous stirring, add sodium dodecylbenzene sulfonate solution to the mixed solution of sodium carbonate and polyacrylic acid, then quickly add the mixed solution of calcium chloride and polyacrylic acid, and stir at low speed for 1 hour at 60°C (low speed is usually controlled At 100-300r / min).

[0049] 6. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com