Inner cooling and ventilating system of large synchronous compensator

An internal cooling and ventilation system technology, applied in the direction of cooling/ventilation devices, electromechanical devices, magnetic circuit static parts, etc., can solve the problems of installation, cumbersome operation, high operating cost, complex structure, etc., and achieve a small number of equipment, improve Cooling efficiency and effect, effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

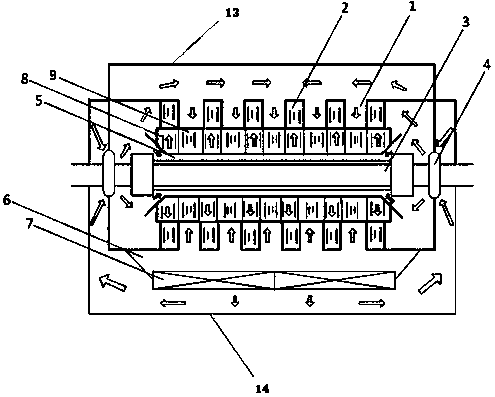

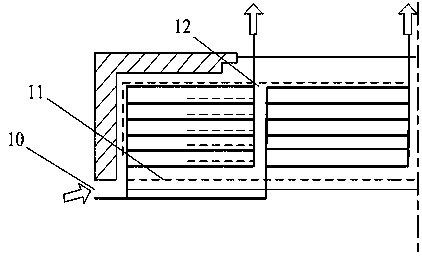

[0020] Embodiment: An internal cooling and ventilation system of a large-scale synchronous camera includes an inner casing 13 , an outer casing 14 , a water-air cooler 7 , and a cooling fan 4 . Among them, the two cooling fans 4 are respectively arranged on the outer sides of the two ends of the rotor 3, and are coaxial with the rotor 3; the water-air cooler 7 is arranged below the stator, and a base air chamber 6 is formed between the stator and the stator; The inner casing 13 is arranged on the periphery of the stator, and is connected with the cooling fan 4 and the water-air cooler 7 to form an inner wind area together; the outer casing 14 is arranged on the periphery of the inner wind area and is connected with the inner casing 13 A closed system is formed; there is an air gap 5 between the stator and the rotor 3; the part of the iron core of the stator close to the outer side is divided into 6 stator core segments 2 with equal lengths by the radial ventilation channel 1; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com