Positioning method of non-conformal surface transformation noise source based on spherical-harmonic function expansion

A technology of spherical harmonic functions and non-conformal surfaces, applied in positioning, measuring devices, instruments, etc., can solve problems such as difficult positioning and identification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] Below in conjunction with accompanying drawing and specific embodiment the invention is further introduced:

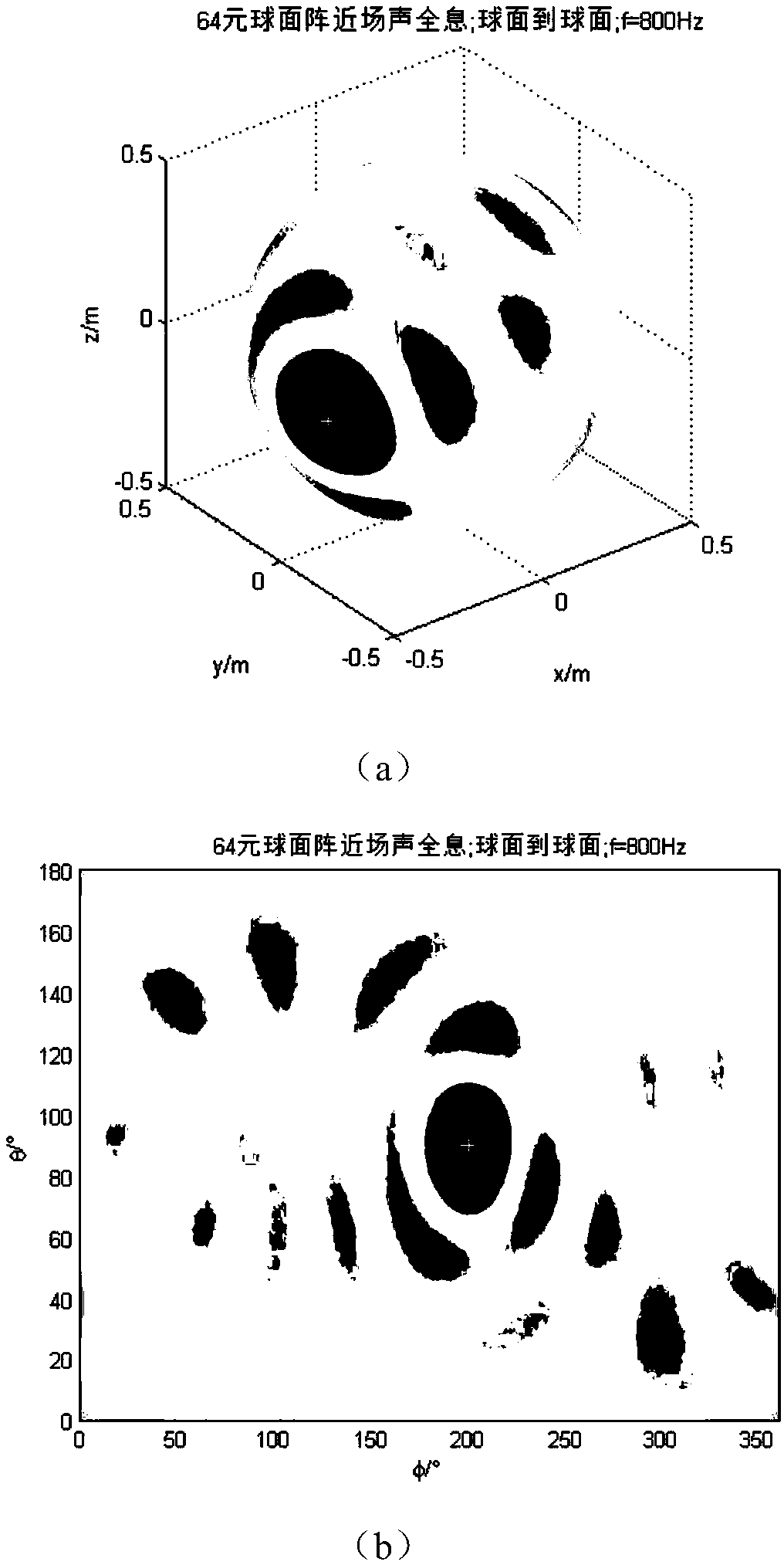

[0060] The data acquisition model of the spherical array noise source is as follows: figure 1 , under open conditions, the spherical array is placed at a certain point in space, the number of elements of the spherical array is Q, and the position of the qth microphone is (x q ,y q ,z q). With the center of the spherical array as the coordinate origin (0, 0, 0), place a sound source at a distance of 0.5m from the center of the spherical array. In the air, the position of the sound source is in cylindrical coordinates (r 0 ', φ 0 , z) is (0.5m, 200°, 0m), in spherical coordinates (r 0 , θ 0 , φ 0 ) is (0.5m, 90°, 200°). The sound source frequency is 800Hz, and Gaussian white noise with SNR=35dB is added in the simulation.

[0061] The flow process of the embodiment of the present invention is as figure 2 As shown, first, the spherical array is used to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com