An automatic test system for friction sensitivity

A technology of automatic testing and friction sensitivity, which is applied in the field of measurement and testing, can solve the problems of high labor intensity, inability to quantify, and low safety, so as to improve safety and production efficiency, avoid manual intervention, and prevent secondary impact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Structure and working process of the present invention are described in detail below in conjunction with accompanying drawing:

[0053] structure

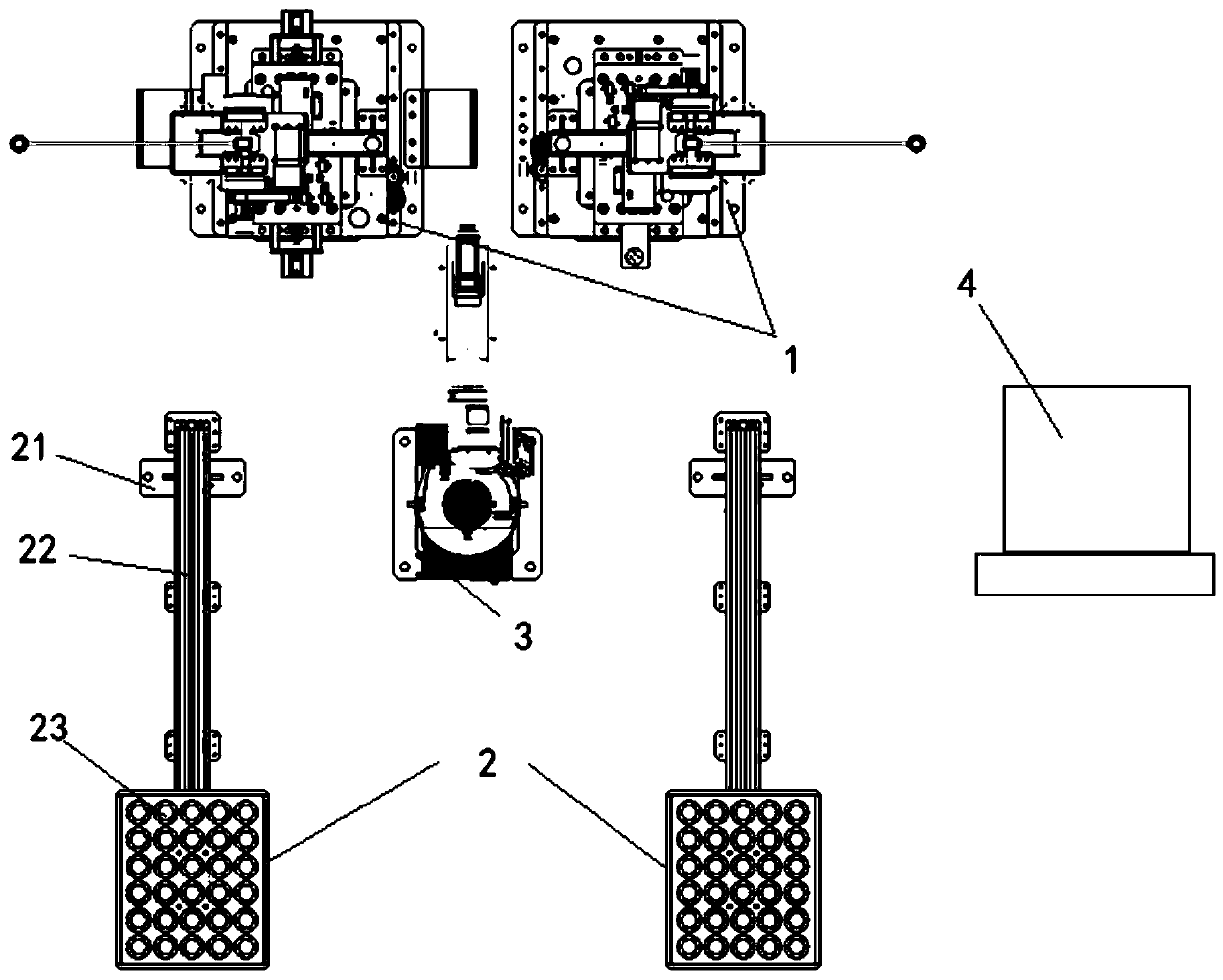

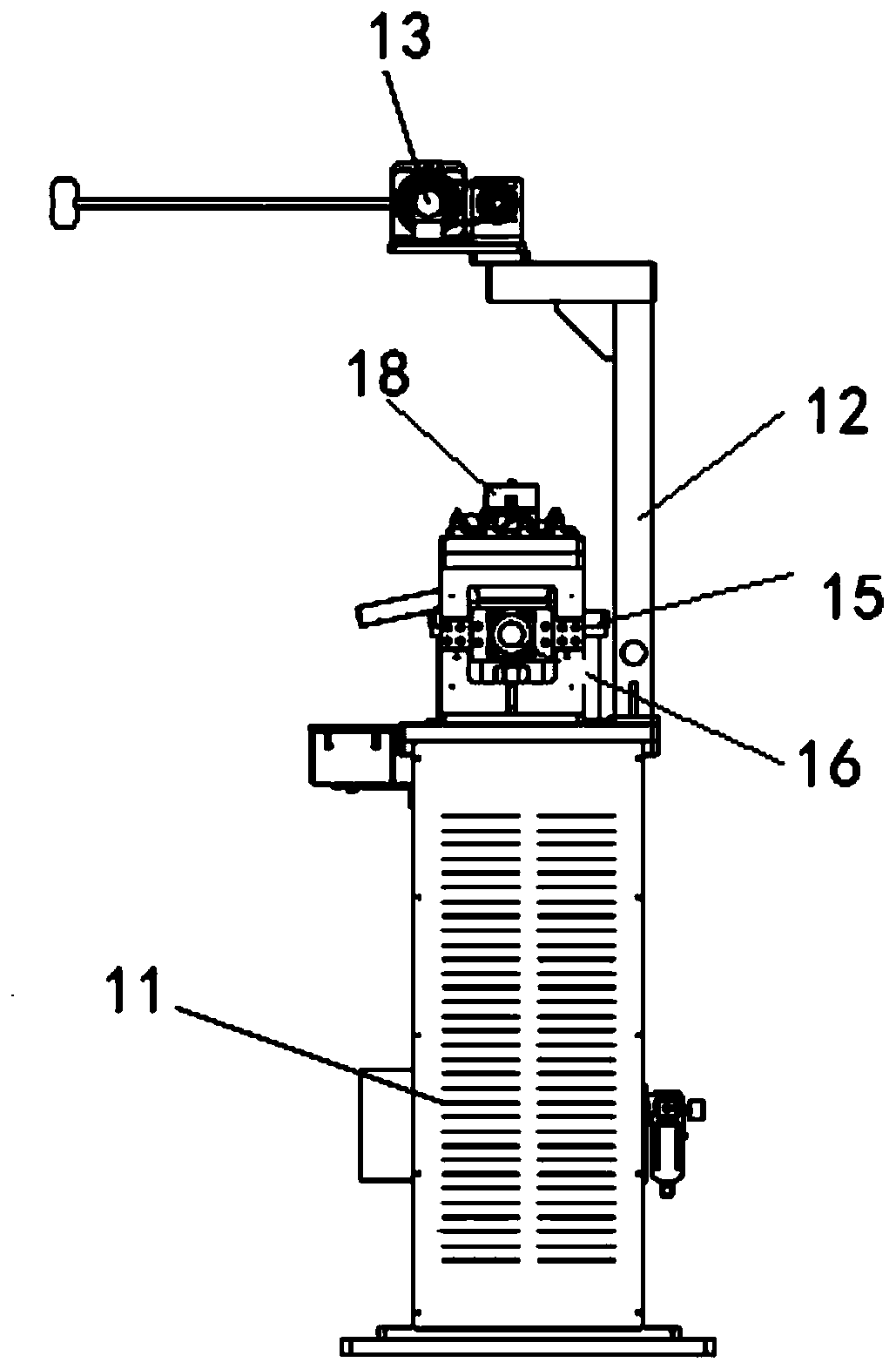

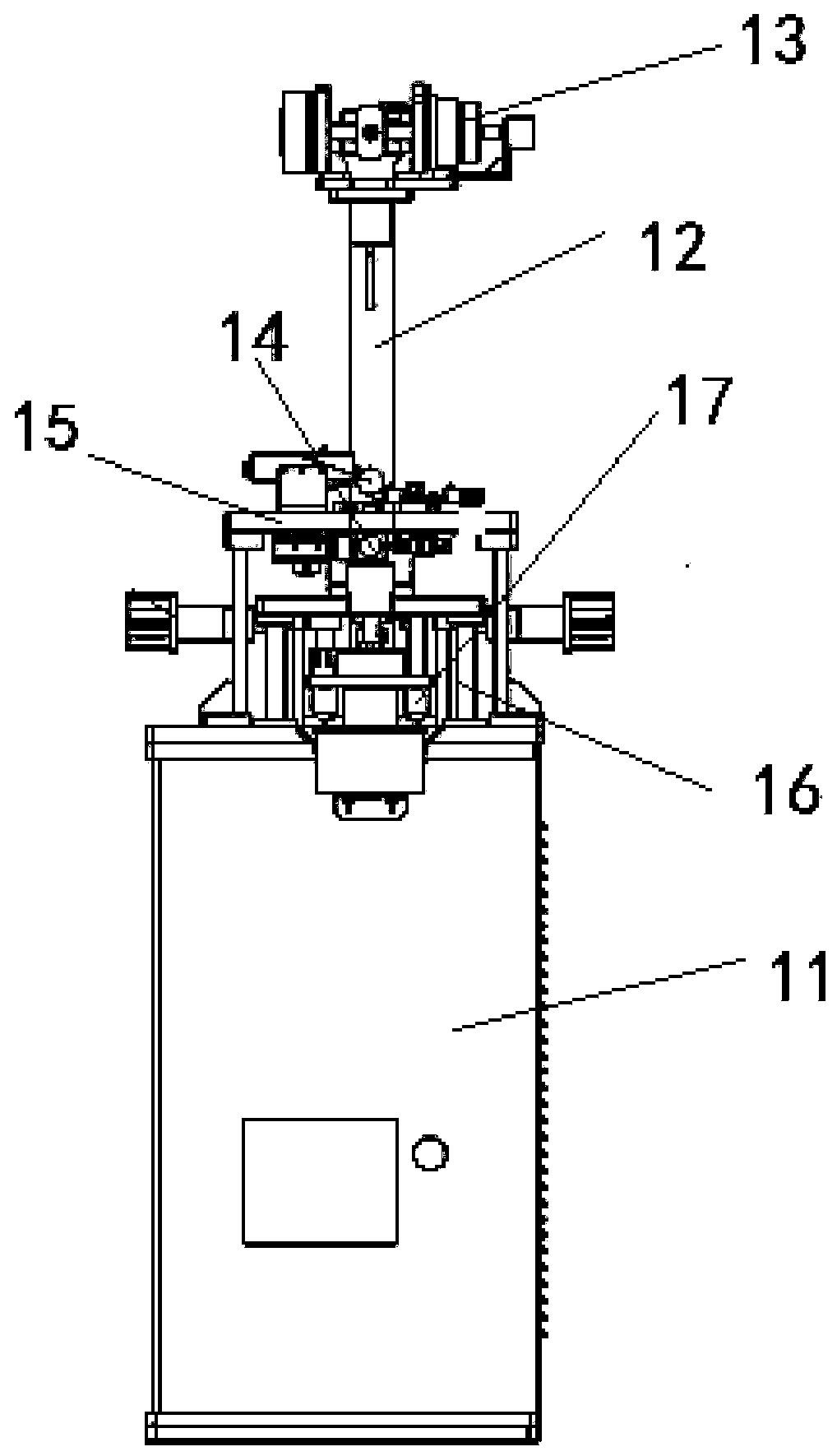

[0054] Such as figure 1 As shown, an automatic test system for impact sensitivity includes a friction test device 1, a conveying device 2, a robot 3 and a control unit 4;

[0055] The friction test device 1 is used for pendulum testing and collecting test data, the conveying device 2 is used to store the samples of pyrotechnics to be tested and tested, and the robot 3 is used to automatically pick and place the samples to be tested and tested between the conveying device and the impact test device. The tested pyrotechnic product sample, the control unit 4 is electrically connected with the friction test device 1, the robot 3 and the delivery device 2 respectively, and it includes an on-site control unit or a remote monitoring station, which is mainly responsible for controlling the friction test device, the delivery device,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com