Multifunctional tube bundle support

A multi-functional, sub-frame technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of complex installation structure, inconvenient installation, and few installation points, so as to simplify the structure, satisfy installation and fixation, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

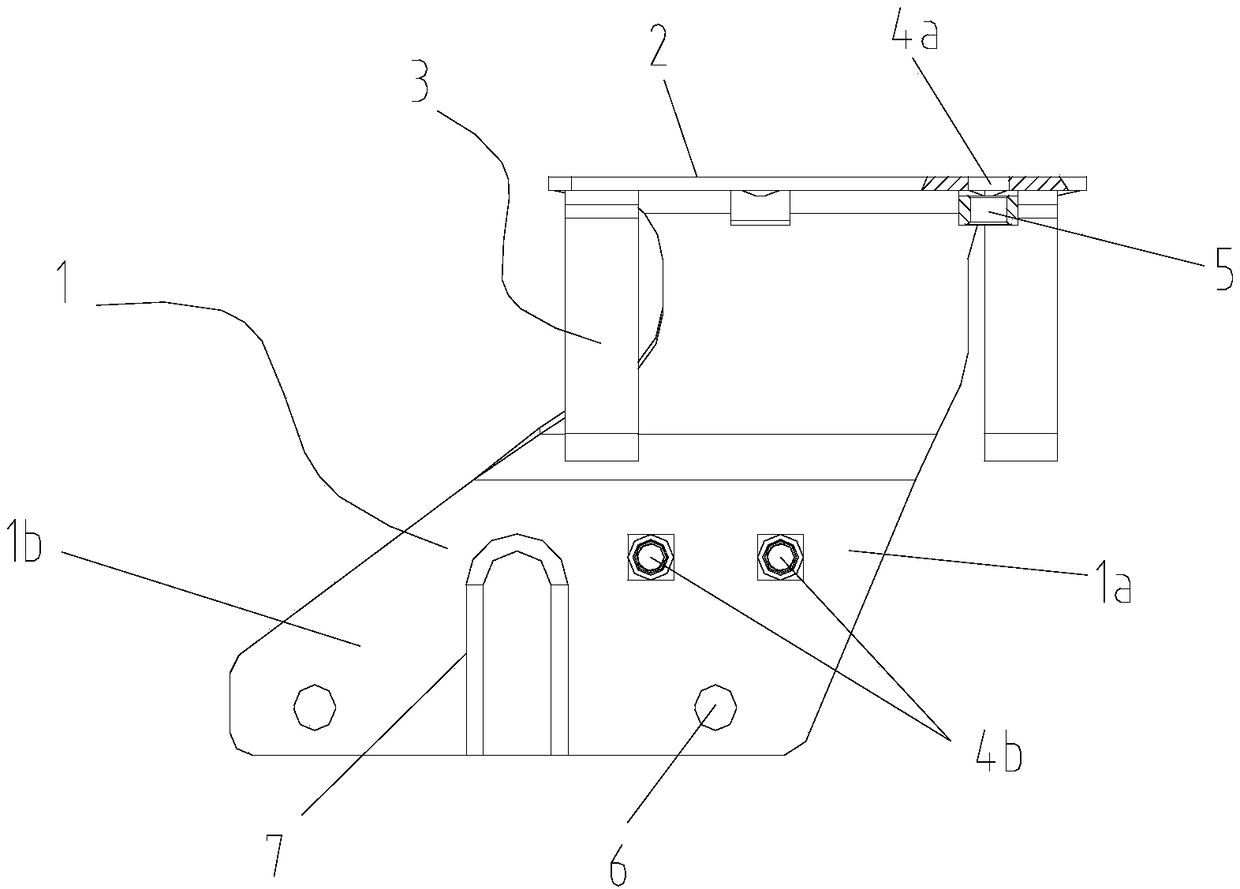

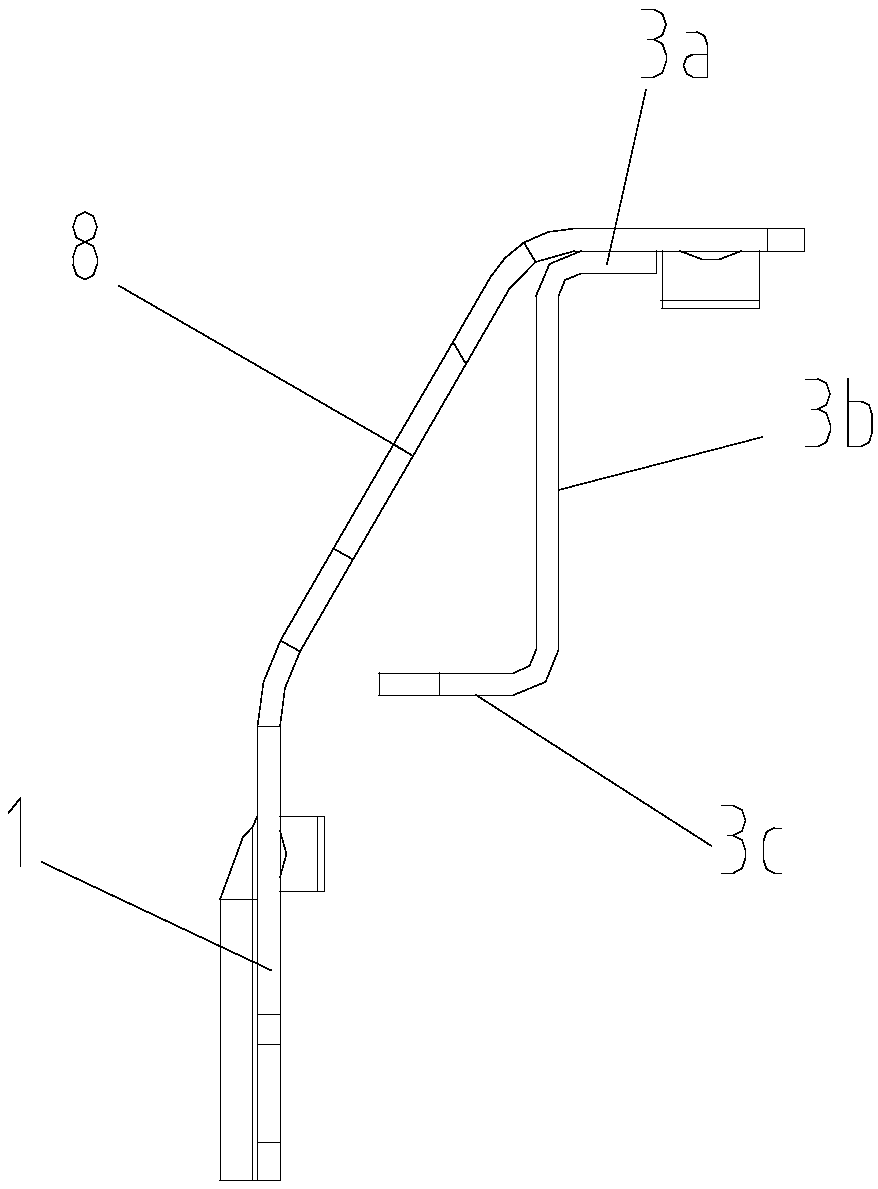

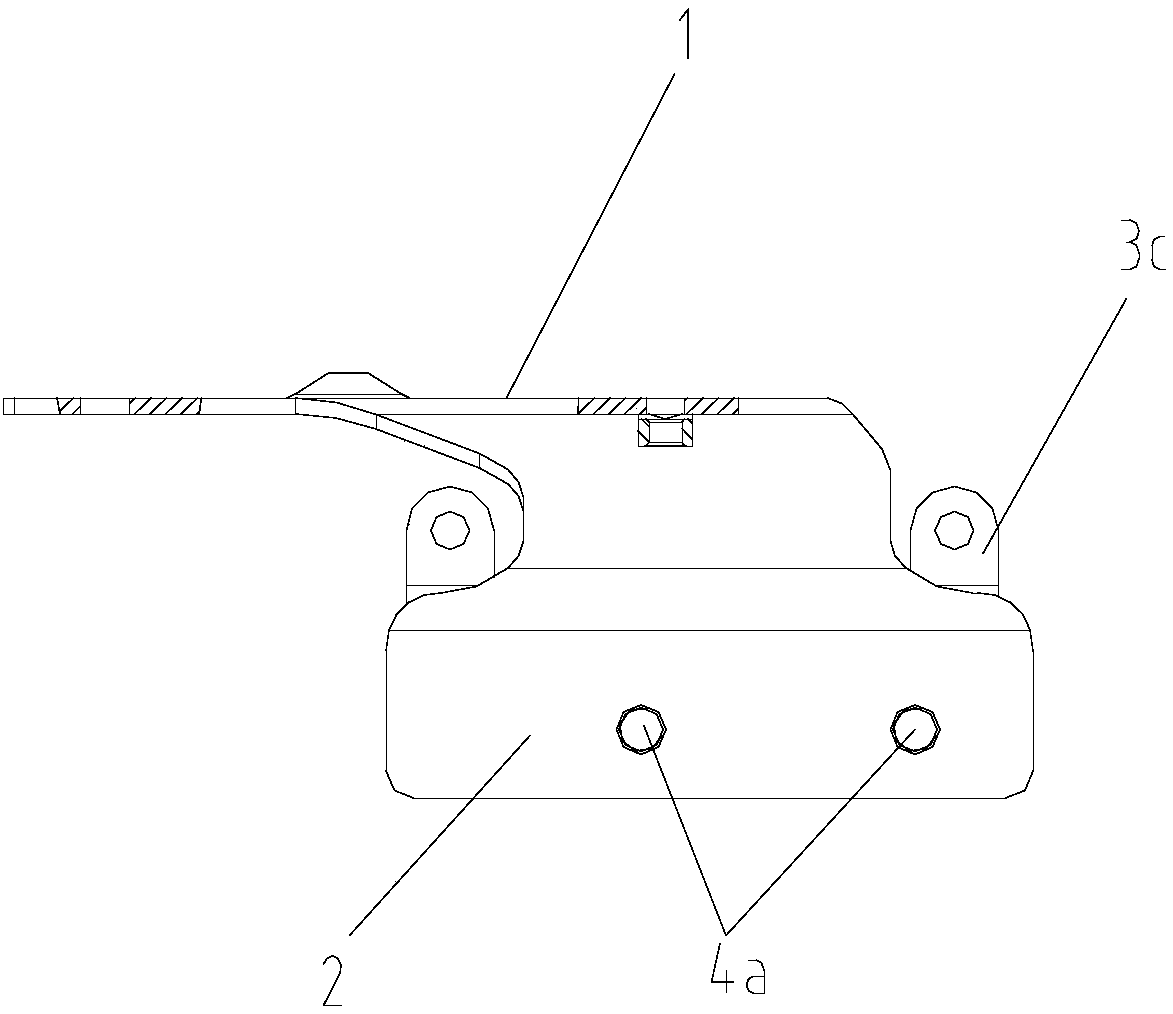

[0016] figure 1 It is a structural schematic diagram of the present invention, as shown in the figure, the multifunctional tube bundle support in this embodiment includes a main frame and a sub-frame 3, the main frame is an inverted L-shaped bent plate, and the bent plate includes a The vertical plate 1 fixed to the engine cylinder head by bolts and the horizontal plate 2 used to be fixed to the engine cylinder head cover are connected and fixed by setting an inclined plate between the vertical plate and the horizontal plate, and the sub-frame is Z The support piece of shape, described support piece is made up of upper flat piece 3a, middle connecting piece 3b and lower flat piece 3c, and described upper flat piece is welded and fixed on the lower surface of horizontal plate, and described lower flat piece is provided with for supporting Fixed to the mounting hole of the engine cylinder head cover, the vertical plate and the horizontal plate are respectively provided with fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com