Big skewback base plate type lining and drainage system structure thereof

A technology of drainage system and large arch seat, applied in drainage, wellbore lining, tunnel lining and other directions, can solve problems such as cracking and damage of tunnel bottom structure, achieve the effect of eliminating effect, convenient excavation operation and reducing investment in engineering construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

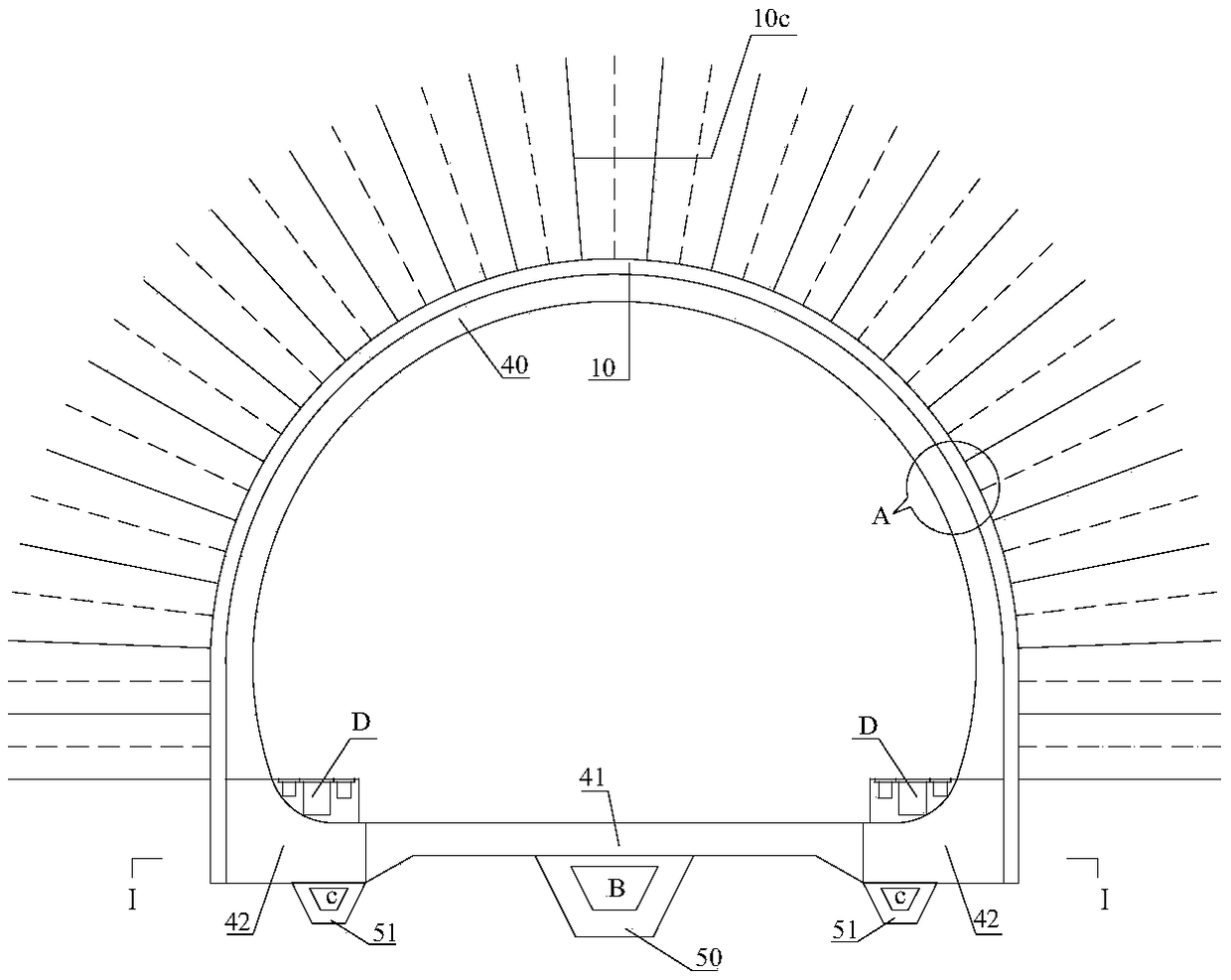

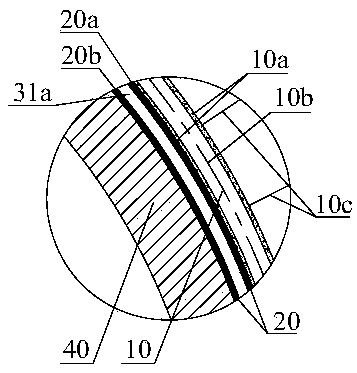

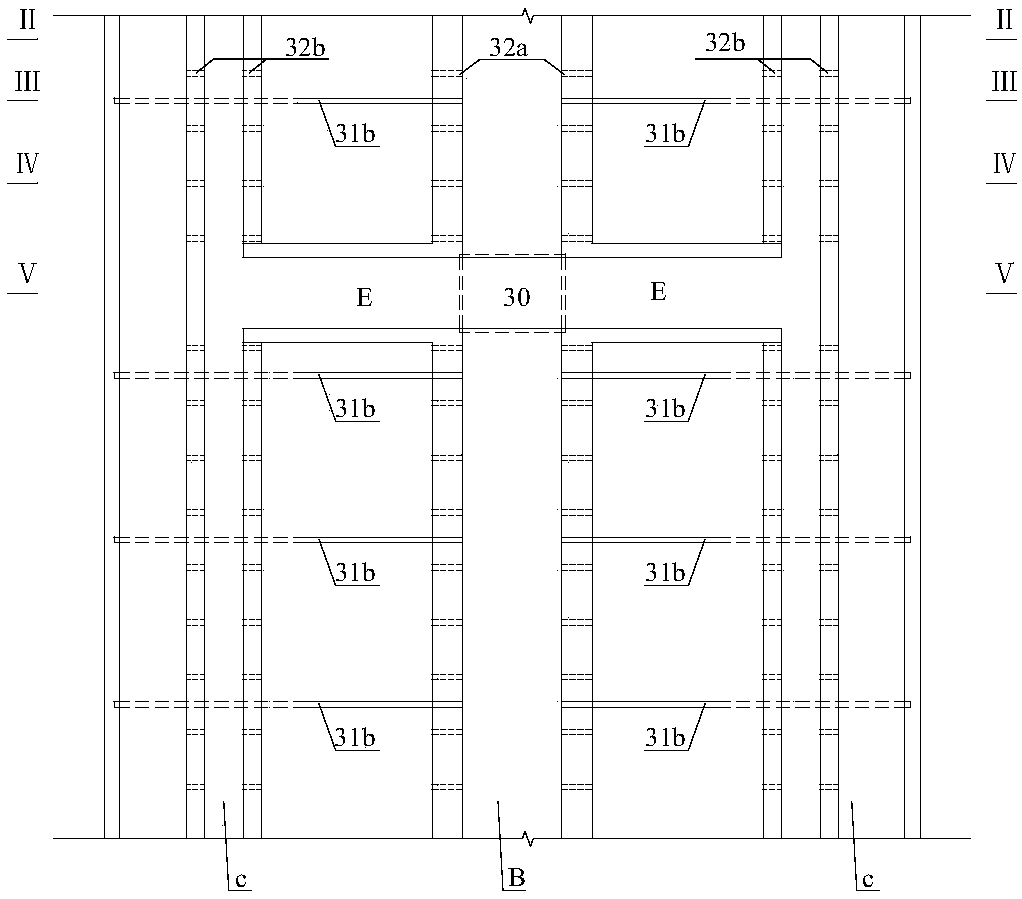

[0043] refer to Figure 1 to Figure 7 , the large abutment floor type lining of the present invention and its drainage system structure include arch wall primary support structure 10, arch wall secondary lining structure 40 and arch wall range waterproof layer 20, and include a drainage system. The bottoms of both sides of the arch wall secondary lining structure 40 are provided with large abutments 42 integrated therewith as a load-bearing foundation, which can effectively increase the load-bearing capacity. A base plate 41 is arranged between the large abutments 42 on both sides, and the two ends of the base plate 41 are respectively consolidated with the large abutments 42 on one side. There is no need to apply concrete fillers on the bottom plate 41, which effectively avoids the destruction of the track structure due to groundwater entering the gap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com