Grate type damper and design method

A design method and damper technology, applied in protective buildings/shelters, building components, earthquake-proof and other directions, can solve the problems of high yield force adjustment cost, large yield displacement, late yielding of dampers, etc., and achieve yield force adjustment. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

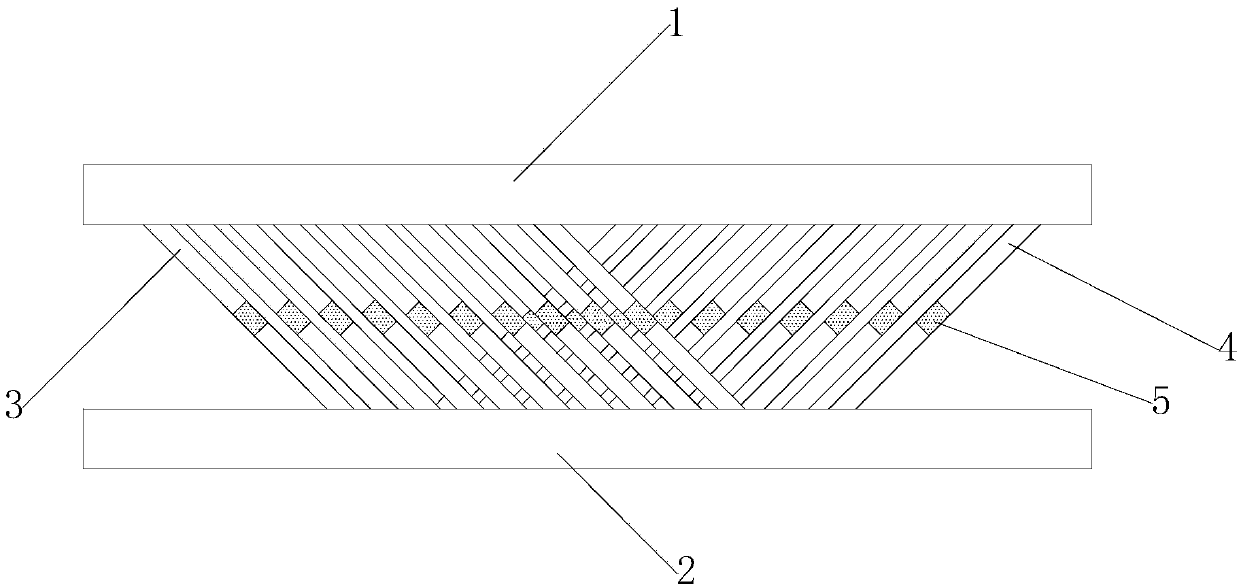

[0040] Specific implementation mode one: as figure 1 — image 3 As shown, a grate damper includes: an upper plate 1, a bottom plate 2, and a group of damper pressing racks 3 and a group of damper pulling racks 4 vertically intersecting;

[0041] The upper plate 1 and the bottom plate 2 are arranged in parallel, and a group of damper pressing racks 3 and a group of damper pulling racks 4 are arranged between the upper plate 1 and the bottom plate 2;

[0042] The lower surface of the upper plate 1 is provided with the upper groove of the damper pressing rack 3 and the upper groove of the damper pulling rack 4 in parallel, and the upper surface of the bottom plate 2 is respectively arranged with the upper groove of the damper pressing rack 3 and the damper pulling rack 4 The upper groove corresponds to the lower groove of the damper pressing rack 3 and the lower groove of the damper pulling rack 4;

[0043] A group of damper pressing racks 3 are arranged in parallel, one end of...

specific Embodiment approach 2

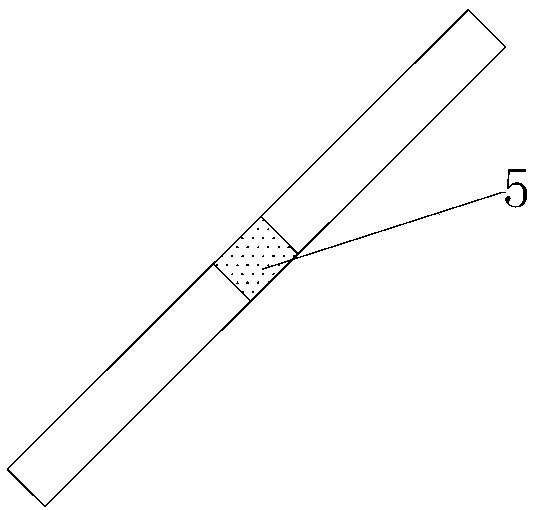

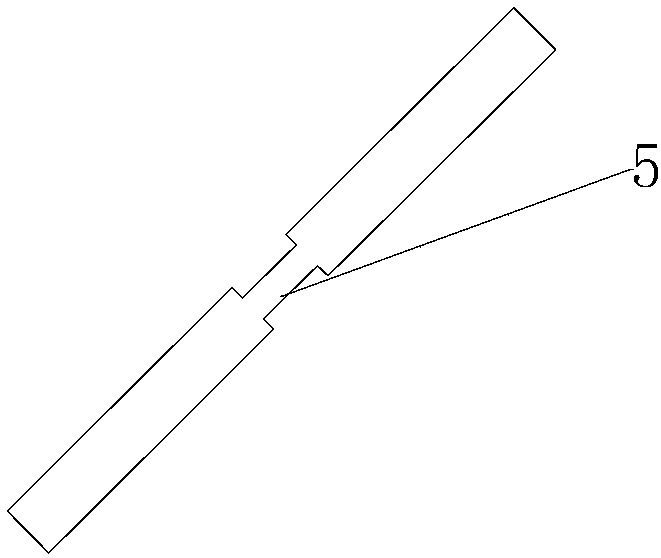

[0046] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the necking section 5 is formed by the depressions provided on the front and rear end surfaces of each damper pressing rack 3 and damper pulling rack 4; Or the necking section 5 is composed of depressions provided on the left and right end surfaces of each damper pressing rack 3 and damper pulling rack 4 .

[0047] Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0048] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the depression is a groove in the width direction of the press rack or pull rack through the damper, or the depression is a press rack through the damper Or pull the groove in the thickness direction of the rack.

[0049] Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com