First-color sealant insert structure of double-color mold

A two-color mold and insert technology, applied in the field of two-color molds, can solve problems such as cost impact, sealing ribs are easy to break, affect product quality and pass rate, and achieve the effect of solving easy breakage and improving mold life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

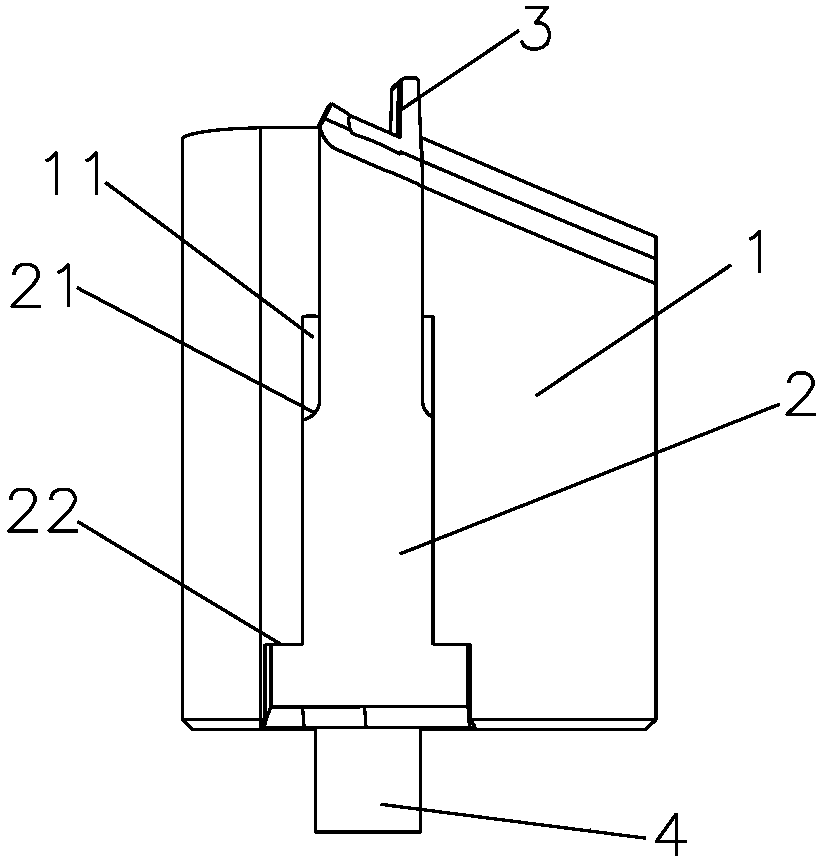

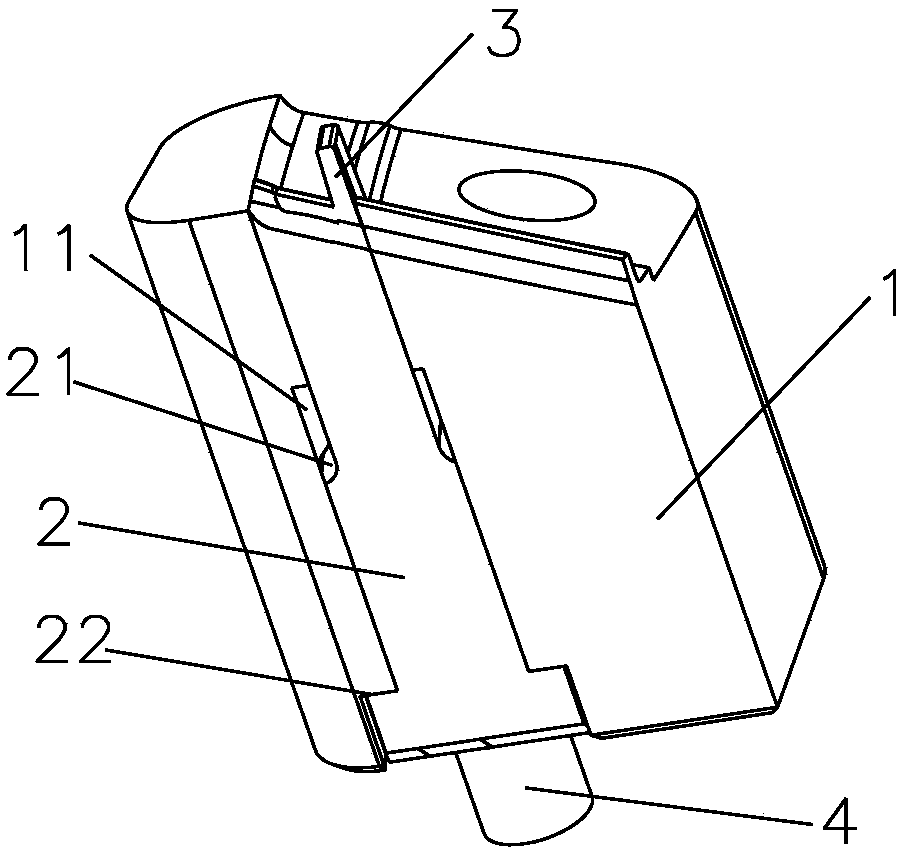

[0014] Such as figure 1 and 2 As shown, a first-color sealant insert structure of a two-color mold includes an insert body 1 and a movable block 2, and the insert body 1 is provided with an installation cavity 11 matching the movable block 2, The movable block 2 is slidably arranged in the installation cavity 11, one end of the movable block 2 is provided with a sealing rib 3, and the other end is provided with an elastic element 4, the elastic element 4 is a spring, and the sealing The rubber ribs 3 protrude from the upper end surface of the insert body 1 .

[0015] Specifically, the size of the upper part of the movable block 2 is smaller than that of the lower part, and a first platform 21 is formed at the junction of the upper part and the lower part, and the upper part and the lower part of the installation cavity match the shape of the movable block 2 respectively. The bottom end of the movable block 2 has a mounting portion, the mounting portion is larger in size to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com