A high-efficiency and low-resistance synergistic device for a desulfurization tower

A desulfurization tower and low-resistance technology, applied in the field of desulfurization, can solve the problems of difficult formation of stable liquid film and unfavorable desulfurization efficiency, and achieve the effects of simple structure, improved desulfurization efficiency, and increased residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

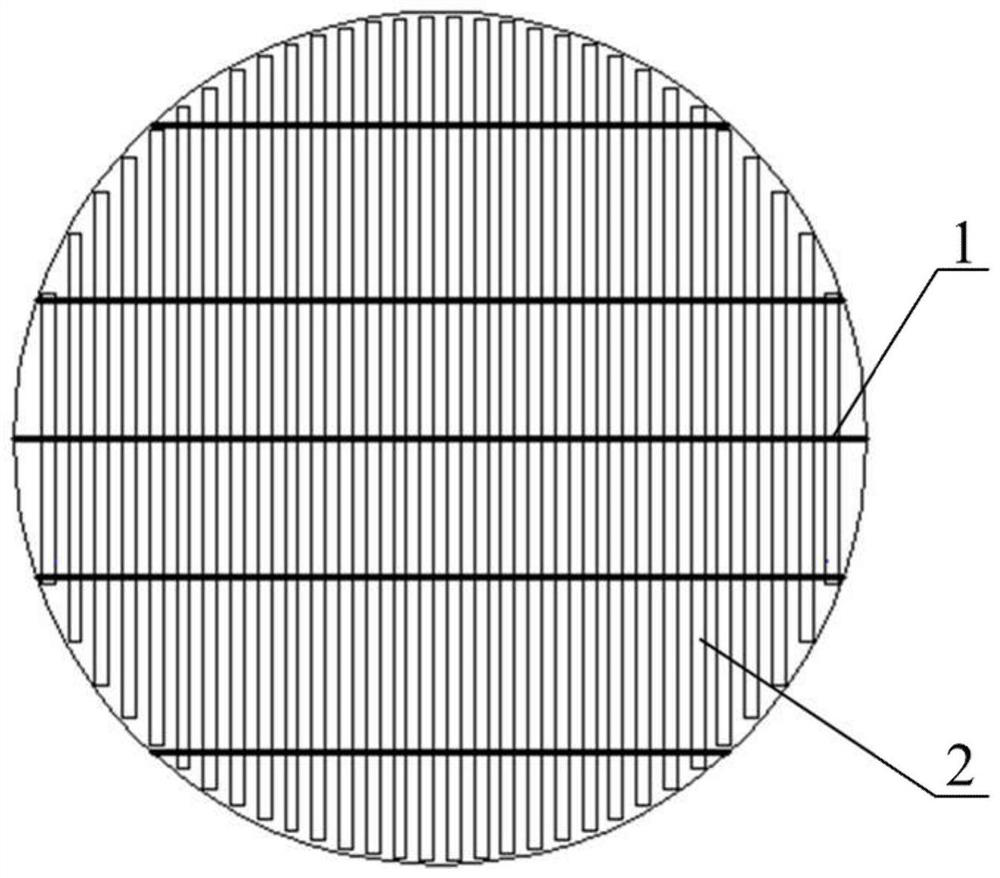

[0036] like Figure 1 to Figure 4 As shown, the present invention provides a high-efficiency and low-resistance synergistic device for a desulfurization tower, at least one layer of turbulent columns is provided, and the turbulent columns are installed at the inlet of flue gas to be desulfurized through a mounting bracket 1, and installed on the Spray layer spray area;

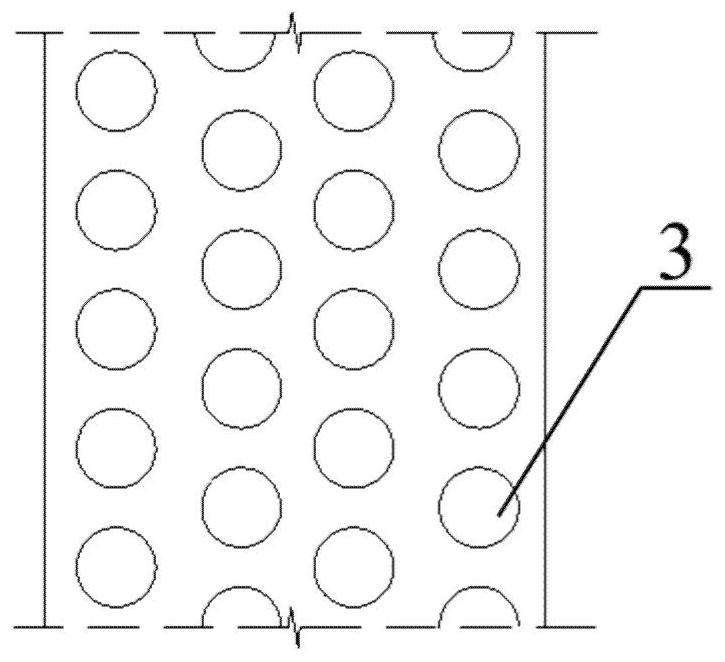

[0037] The spoiler row includes a disturbing flow member 2, the cross section facing the desulfurization slurry spraying direction is a semi-circular arch, and the semi-circular arch is provided with a through hole 3 through which the flue gas and desulfurization slurry can pass, and the cross-section of the spoiler 2 is is semicircular.

[0038] The spoilers 2 on the same spoiler row are evenly distributed;

[0039] The through holes 3 are evenly distributed on the spoiler 2 .

[0040] The diameter of the semicircular section of the spoiler 2 is D, the gap between two adjacent spoilers 2 on the same spoile...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com