Small-pump strong-back-flow and large-pump single-outpouring type combined pump valve

A compound pump and large pump technology, which is applied in the direction of pumps, pump devices, pump components, etc., can solve the problems of reducing and losing a large number of injection channels and small amount of injection channels to prevent backflow and blockage, so as to reduce manufacturing costs, Effect of reducing wear and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

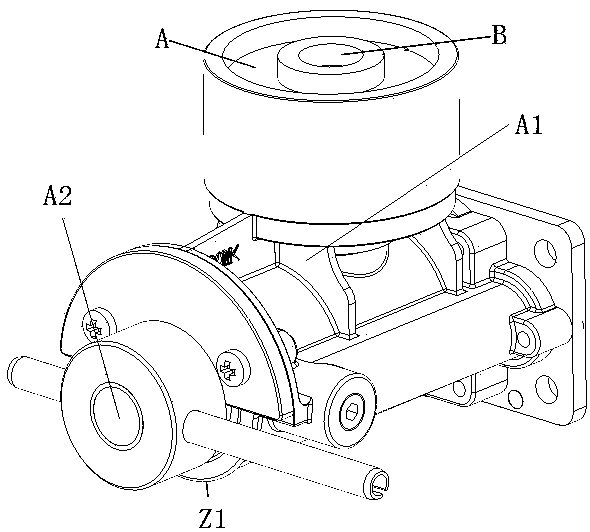

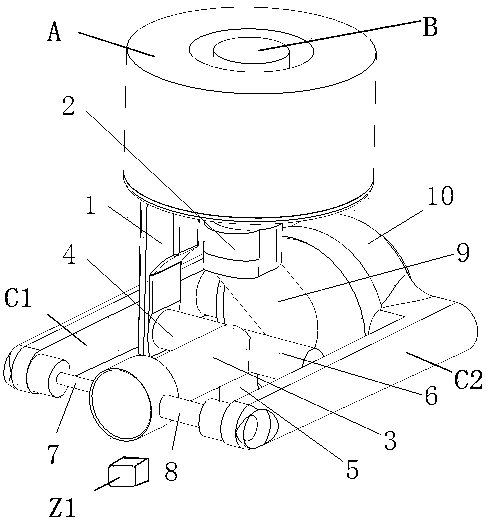

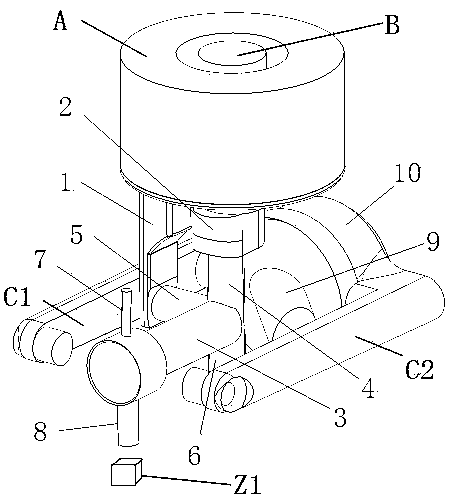

Image

Examples

Embodiment Construction

[0052] Below in conjunction with accompanying drawing, specific embodiment of the present invention is described in further detail:

[0053] Such as Figure 18-Figure 21 As shown, the small pump strong backflow large pump single-injection compound pump valve, the valve body is provided with a large pump inlet and outlet 60 and a small pump inlet and outlet 61, the shaft center passage 62 of the valve core is provided with a first radial passage 63 and a second radial passage 63 Two radial passages 64, one end of the axis passage 62 of the spool is also provided with an injection passage 65, the other end of the spool is provided with an inclined passage 66, and one end of the inclined passage 66 is connected to the color paste bucket inlet and outlet 67, wherein the pump When the valve is in the backflow state of the initial position, the axes of the large pump inlet and outlet 60, the small pump inlet and outlet 61, the first radial passage 63 and the second radial passage 64...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com