A modular same-floor drainage device for buildings and its installation method

A same-layer drainage and modular technology, applied in water supply installations, buildings, building structures, etc., can solve the problems of leakage in the subsidence area, long construction period, and the inability to seal the installation of side drainage toilets, so as to improve the replacement frequency. , the effect of avoiding leakage hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

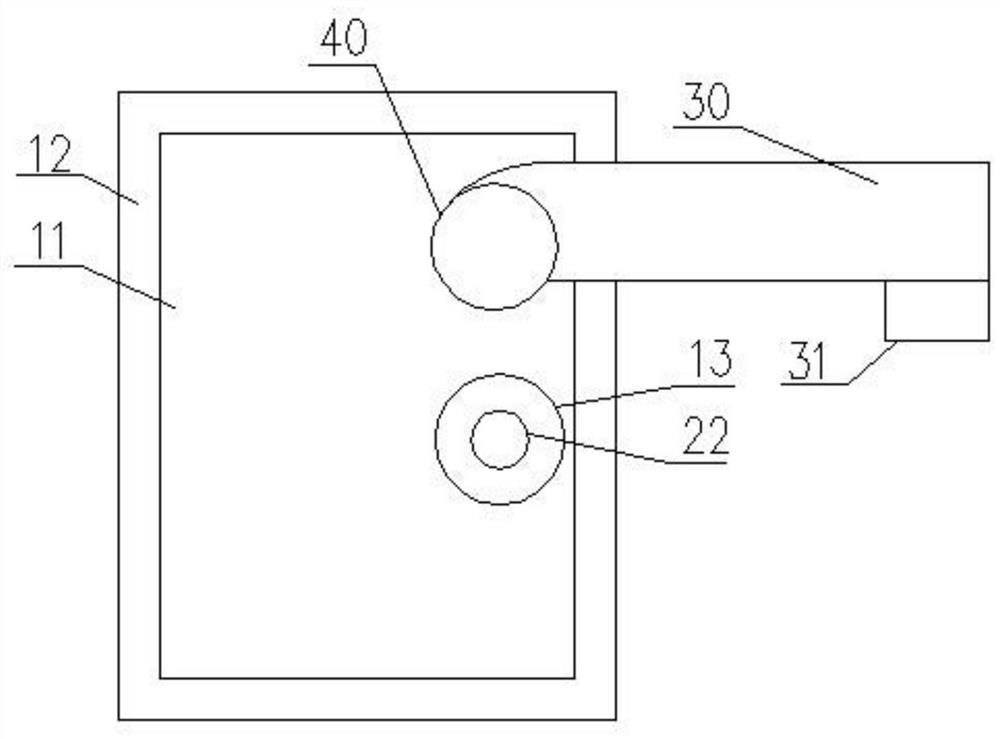

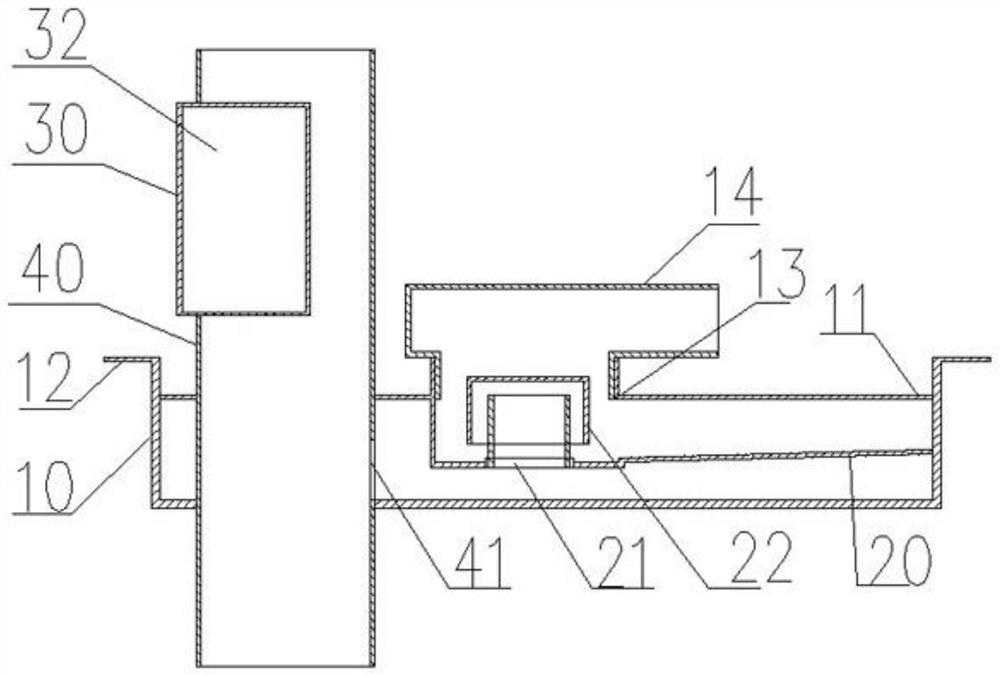

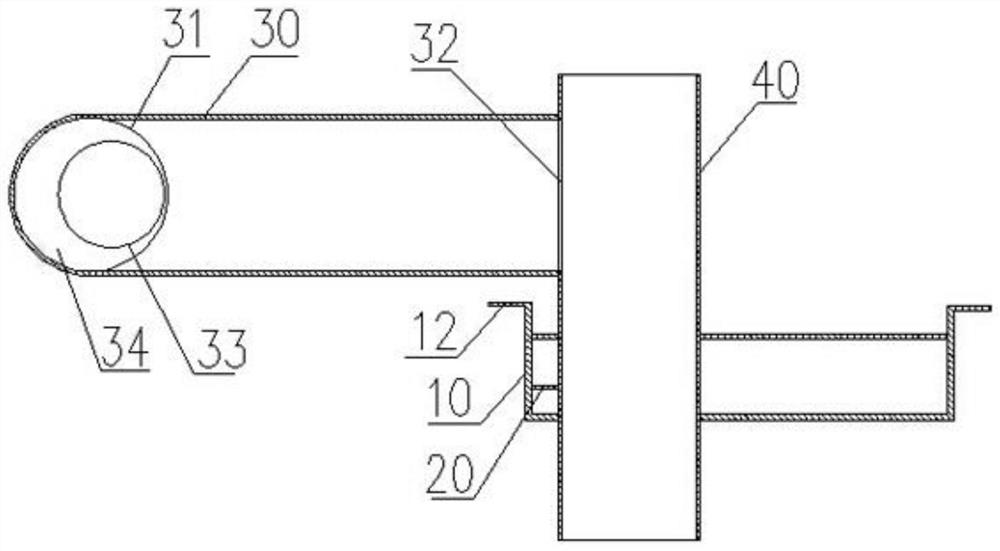

[0059] Such as Figure 1-3 As shown, a modular same-floor drainage device for buildings includes a water collection tank 10, a riser connecting pipe 40 pierced in the water collection tank 10, and a waste water discharge inlet 13 provided on the top cover 11 of the water collection tank. The connecting pipe 40 is provided with a water outlet 41 located in the water collection tank, the waste water discharge inlet 13 is connected with the water outlet 41 by a water seal mechanism, and the waste water discharge inlet 13 is equipped with a waste water drain pipe 14; the waste water drain pipe cross section is rectangular, The upper edge of the water collection tank 10 is outwardly provided with a flange 12; the riser connecting pipe 40 is connected with a side row connector, and the side row connector includes a flat sewage tank 30, and the sewage tank 30 is connected to the riser connecting pipe The connecting end of 40 is provided with a sewage outlet 32, and the side wall of t...

Embodiment 2

[0061] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the relative position of the standpipe connecting pipe 40 and the waste water discharge port 13 is changed, and the cross section of the waste water discharge pipe is circular, and the top cover 11 of the water collection tank also has a A drain hole 16 communicating with the water collection tank 10 is provided.

[0062] Two water sealing mechanisms can be provided in this embodiment, and the drain holes communicate with one water sealing mechanism and the waste water discharge port communicates with the other water sealing mechanism.

Embodiment 3

[0064] Such as Figure 5 As shown, the difference between this embodiment and Embodiment 2 is that the relative position of the standpipe connecting pipe 40 and the waste water discharge port 13 is changed, and an inspection hole 15 is also provided on the top cover of the water collection tank, and the inspection hole 15 corresponds to the water inlet. Envelope settings.

[0065] Such as Figure 7 As shown, the installation method of the modular same-floor drainage device for buildings described in this embodiment in the cast-in-place reinforced concrete floor structure toilet, the steps are as follows:

[0066] 1) An installation hole is reserved on the structural floor 60 of the bathroom, and the installation hole of the floor slab is aligned on the upper and lower floors before installation, so that the center line of the floor installation hole on each floor is perpendicular to the horizontal ground;

[0067] 2) Support the formwork at the bottom of the installation hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com