Modularization same-layer drainage device for high-rises and mounting method thereof

A same-layer drainage, modular technology, applied in water supply installations, drainage structures, waterway systems, etc., can solve the problems of long construction period, inconvenient decoration, errors, etc., and achieve the effect of avoiding hidden leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

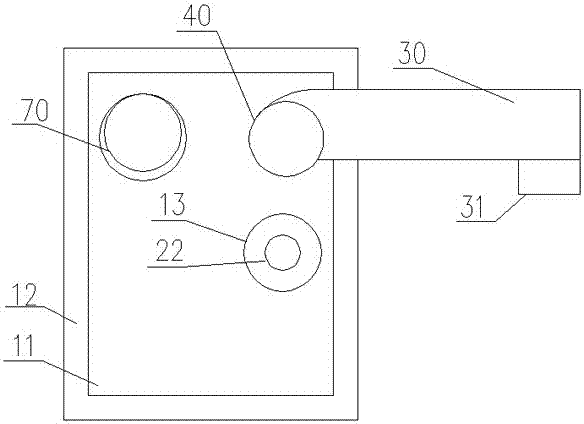

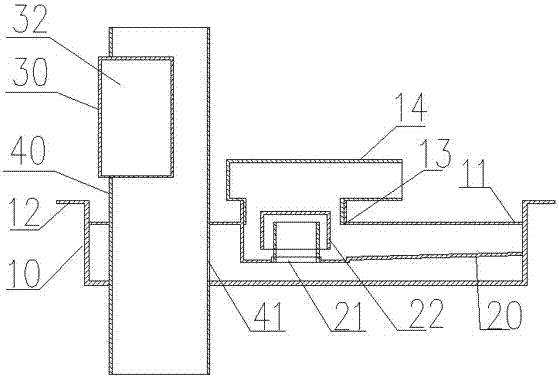

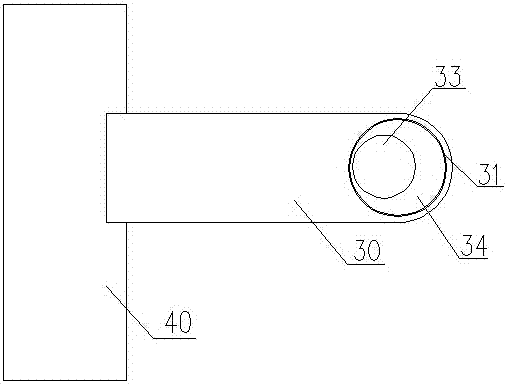

[0056] like Figure 1-4 As shown, it includes a collecting tank 10, a riser connecting pipe 40 that penetrates the collecting tank 10, a lower vent pipe 71 that passes through the bottom wall of the collecting tank 10 and is equal to the highest position of the top cover 11 of the collecting tank, and is arranged in the collecting tank 10. The upper ventilation pipe 70 on the top cover 11 of the water tank and communicated with the inside of the water collection tank 10, and the waste water discharge port 13 opened on the top cover 11 of the collection tank, there is a gas flow channel between the upper ventilation pipe 70 and the lower ventilation pipe 71, The pipe connecting pipe 40 is provided with a water outlet 41 located in the water collecting tank, the top of the lower vent pipe 71 is not lower than the highest point of the water outlet 41, the waste water discharge inlet 13 is communicated with the water outlet 41 through a water seal mechanism, and the waste water dis...

Embodiment 2

[0058] like Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that the lower vent pipe 71 is lower than the top cover 11 of the header tank at the highest point, and the upper vent pipe 70 is a straight pipe and is arranged corresponding to the lower vent pipe 71 .

Embodiment 3

[0060] like Image 6 As shown, the difference between this embodiment and Embodiment 1 is that the relative positions of the standpipe connecting pipe 40 and the waste water discharge port 13 are changed, and the cross section of the waste water discharge pipe is circular. There is a drain hole 16 communicating with the catchment tank 10 .

[0061] In this embodiment, two water sealing mechanisms may be provided, and the drain hole is independently connected to one water sealing mechanism, and the waste water discharge port is connected to the other water sealing mechanism.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com