Preparation method of artificial snow for laying ski run

A technology for artificial snow and ski slopes, applied in chemical instruments and methods, and other chemical processes, can solve problems such as unfavorable development, high energy consumption, and high cost, and achieve good market application prospects, good water retention performance, and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

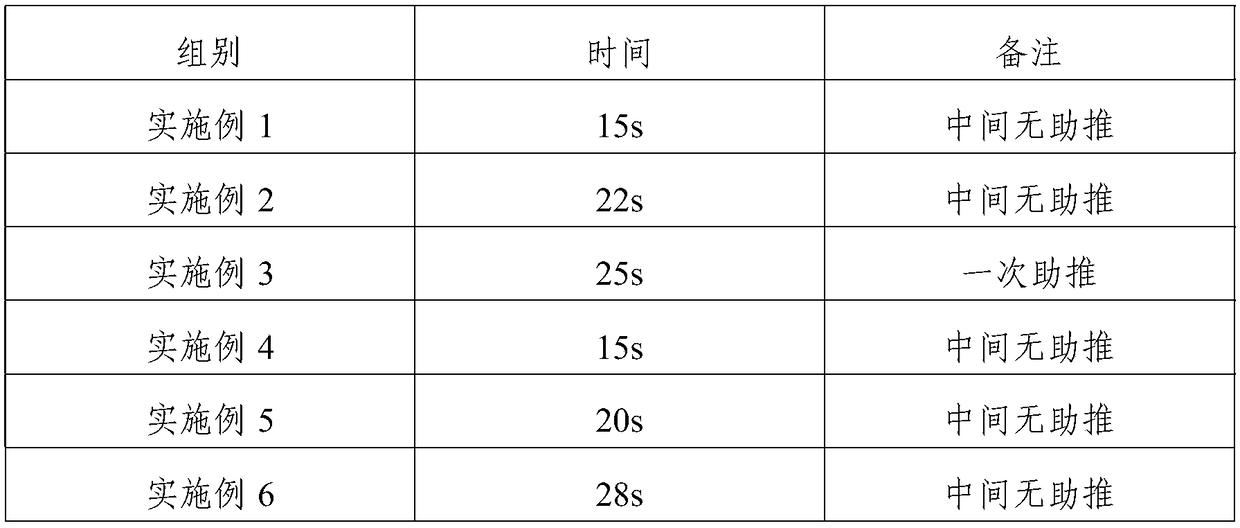

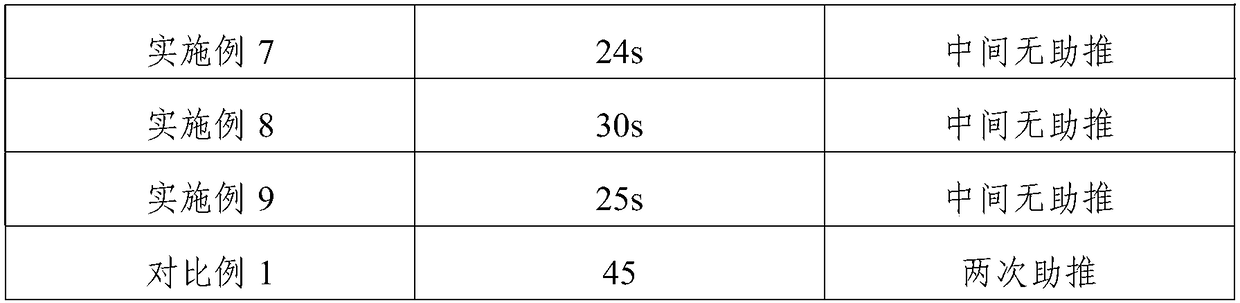

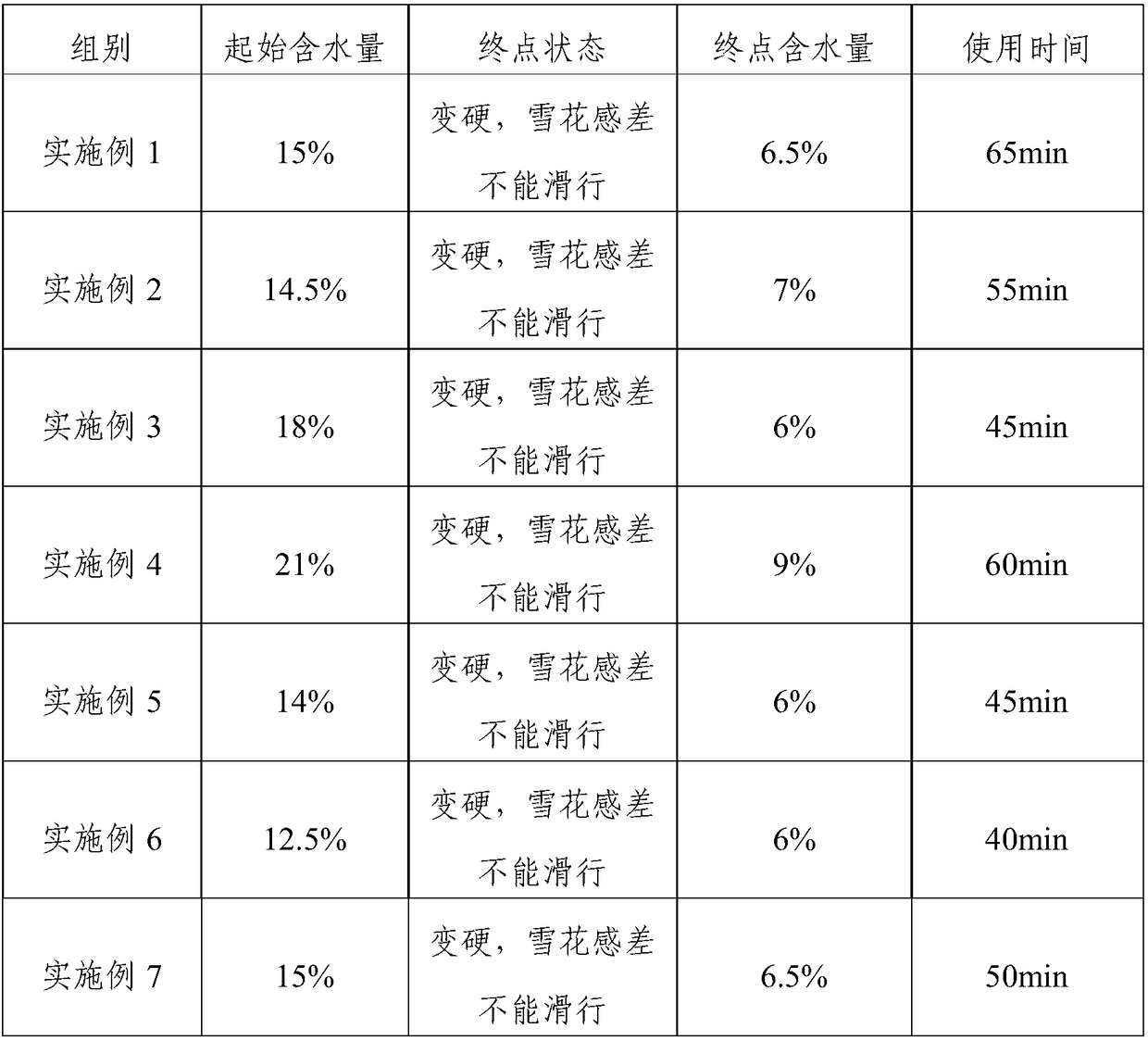

Examples

Embodiment 1

[0018] This embodiment provides a kind of artificial snow for laying ski tracks, which is prepared by the following method:

[0019] Will D 90 200g of 100μm sodium chloride crystals, immersed in an aqueous solution containing 0.1% sodium carboxymethyl cellulose and 0.2% glycerin by mass percentage, first stand for 10 minutes, ultrasonically treat for 5 minutes, then stand for 10 minutes, and filter out the crystals , dried at 60°C for 50 minutes, fully mixed the dried crystals with 2.5 g of water fluffy granular sodium polyacrylate (after absorbing 40 ml of water and then mixed with the crystals) to obtain the product.

Embodiment 2

[0021] This embodiment provides a kind of artificial snow for laying ski tracks, which is prepared by the following method:

[0022] Will D 90 Submerge 200 g of sodium chloride crystals with a diameter of 120 μm in an aqueous solution containing 0.08% sodium carboxymethylcellulose and 0.4% glycerin by mass percentage, first let stand for 10 minutes, ultrasonically treat for 5 minutes, then let stand for 10 minutes, and filter out the crystals. Dry at 60°C for 50 minutes, fully mix the dried crystals with water fluffy granule PET 4g (after absorbing 40ml of water and then mix with the crystals) to obtain the product.

Embodiment 3

[0024] This embodiment provides a kind of artificial snow for laying ski tracks, which is prepared by the following method:

[0025] Will D 90 Submerge 200g of 80 μm sodium chloride crystals in an aqueous solution containing 0.3% sodium carboxymethyl cellulose and 0.2% glycerin by mass percentage, let it stand for 10 minutes, ultrasonically treat it for 5 minutes, then let it stand for 10 minutes, and filter out the crystals. Dry at 60°C for 50 minutes, fully mix the dried crystals with 4g of water fluffy PET particles (after absorbing 30ml of water and then mix with the crystals) to obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com