Tablet collecting device for tablet press

A collection device and tablet press technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of frequent shutdown, inconvenience, low efficiency, etc., and achieve the effect of flexible operation and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

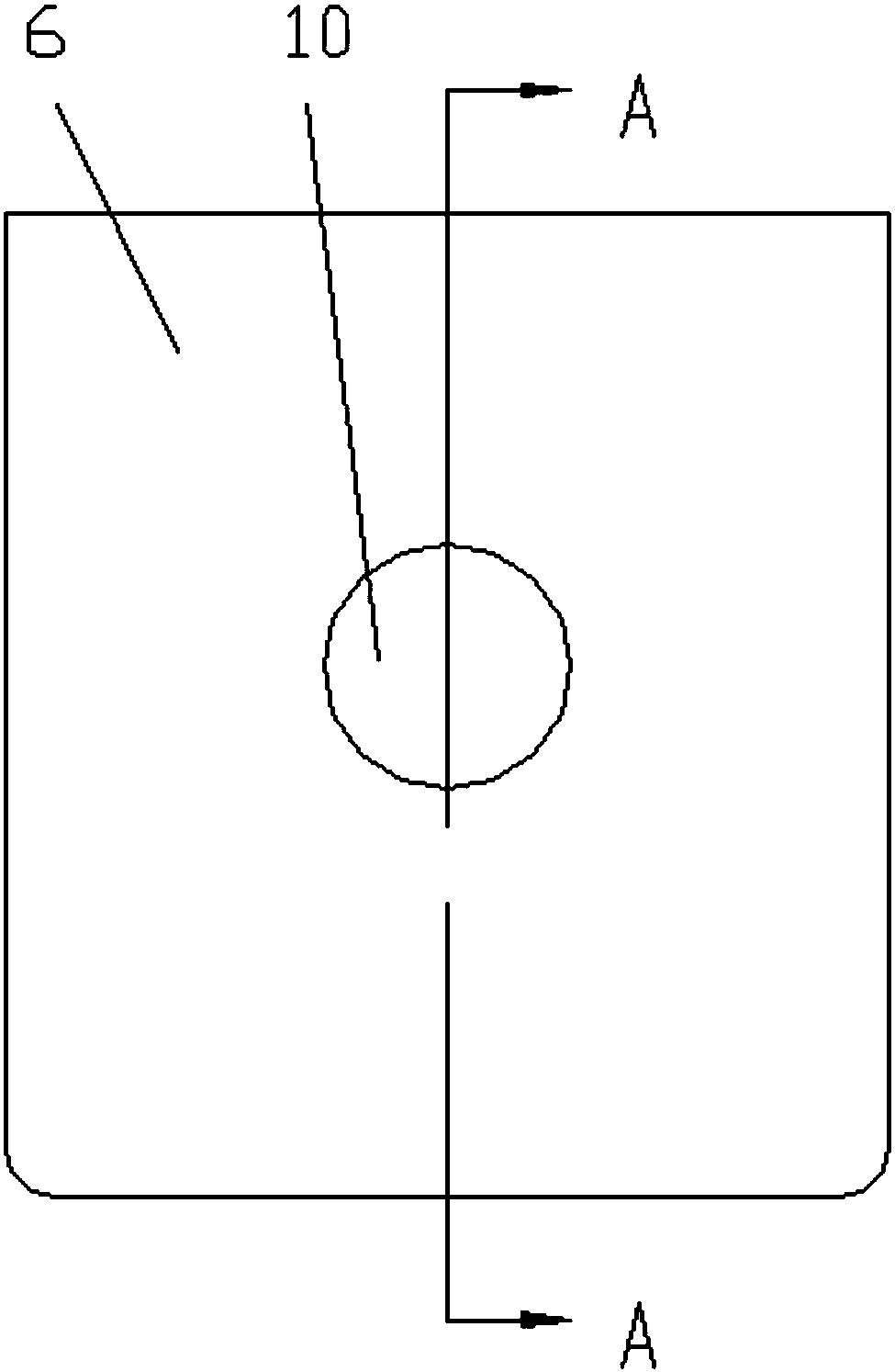

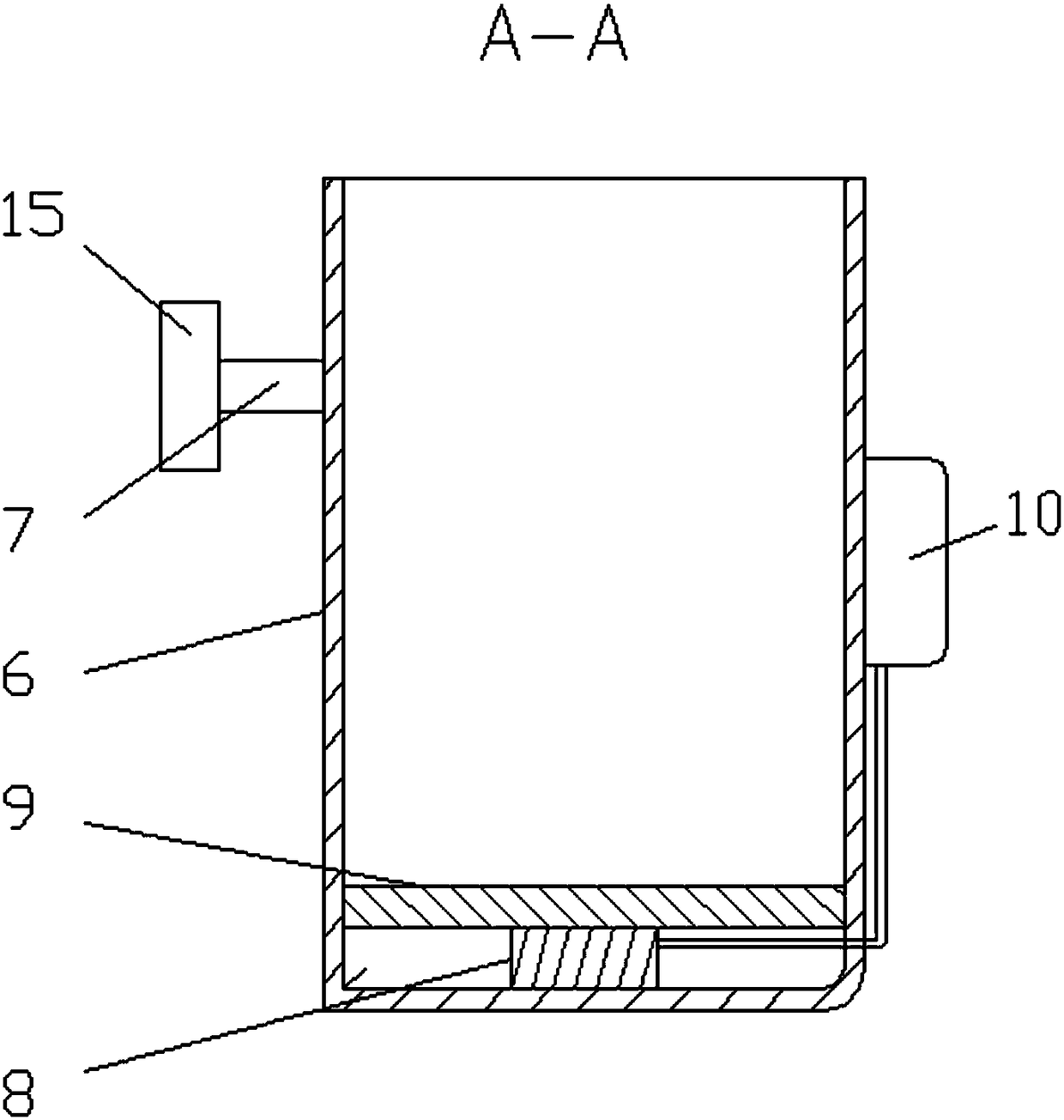

[0020] Such as Figure 1 to Figure 3 As shown, a tablet collection device for a tablet press includes a base plate 3, a slideway 4, a collection barrel 6 and a weighing mechanism. The base plate 3 is installed on the side of the tablet press body 1 through bolts and is located Below the discharge port 2 of the chip machine, the slideway 4 is welded and fixed on the base plate 3 horizontally, the side of the collecting bucket 6 is connected with a support rod 7, and the end of the support rod 7 is connected with a slider 5, and the slider 5 Slidingly connected with the inside of the slideway 4, the middle part of the slideway 4 is provided with a gap 15 for taking out the slide block 5, and the weighing mechanism is also installed in the collecting bucket 6.

[0021] In this embodiment, the weighing mechanism includes a loading plate 9 and a load cell 8, the loading plate 9 is slidably connected on the inner wall of the material collection bucket 6, and the load cell 8 is insta...

Embodiment 2

[0023] Such as Figure 4 to Figure 6 As shown, a tablet collection device for a tablet press includes a base plate 3, a slideway 4, a collection barrel 6 and a weighing mechanism. The base plate 3 is installed on the side of the tablet press body 1 through bolts and is located Below the discharge port 2 of the chip machine, the slideway 4 is welded and fixed on the base plate 3 horizontally, the side of the collecting bucket 6 is connected with a support rod 7, and the end of the support rod 7 is connected with a slider 5, and the slider 5 Slidingly connected with the inside of the slideway 4, the middle part of the slideway 4 is provided with a gap 15 for taking out the slider 5, and the weighing mechanism is also installed in the collecting bucket 6, and the weighing mechanism includes a loading plate 9 and a load cell 8, the loading plate 9 is slidably connected on the inner wall of the material collection bucket 6, the load cell 8 is installed on the bottom of the material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com