Heat radiator water chamber machining mold realizing multiple purposes by one mold

A technology for processing molds and radiators, which is applied in the field of processing molds for radiator water chambers, can solve the problems of high mold manufacturing costs and inability to adapt to the production of various types of water chambers, and achieve the effect of changing positions and specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

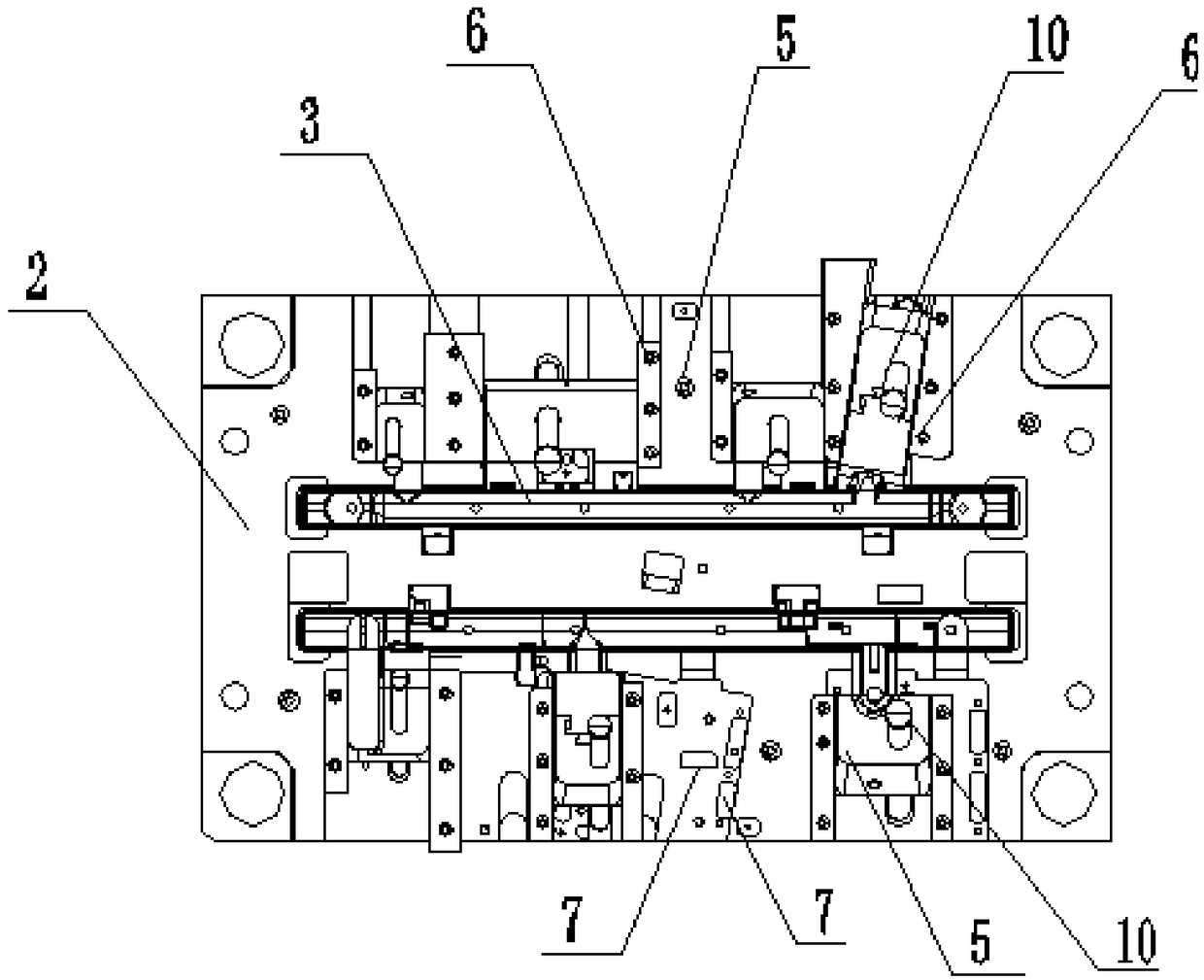

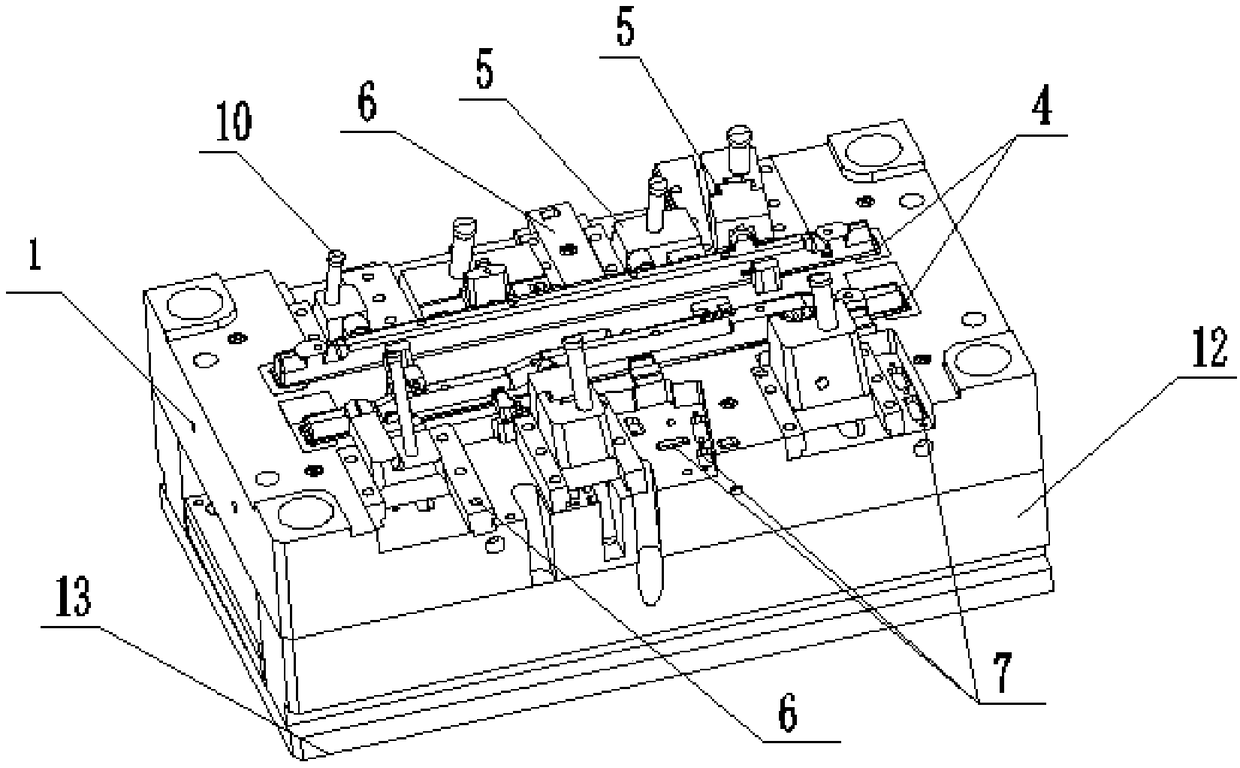

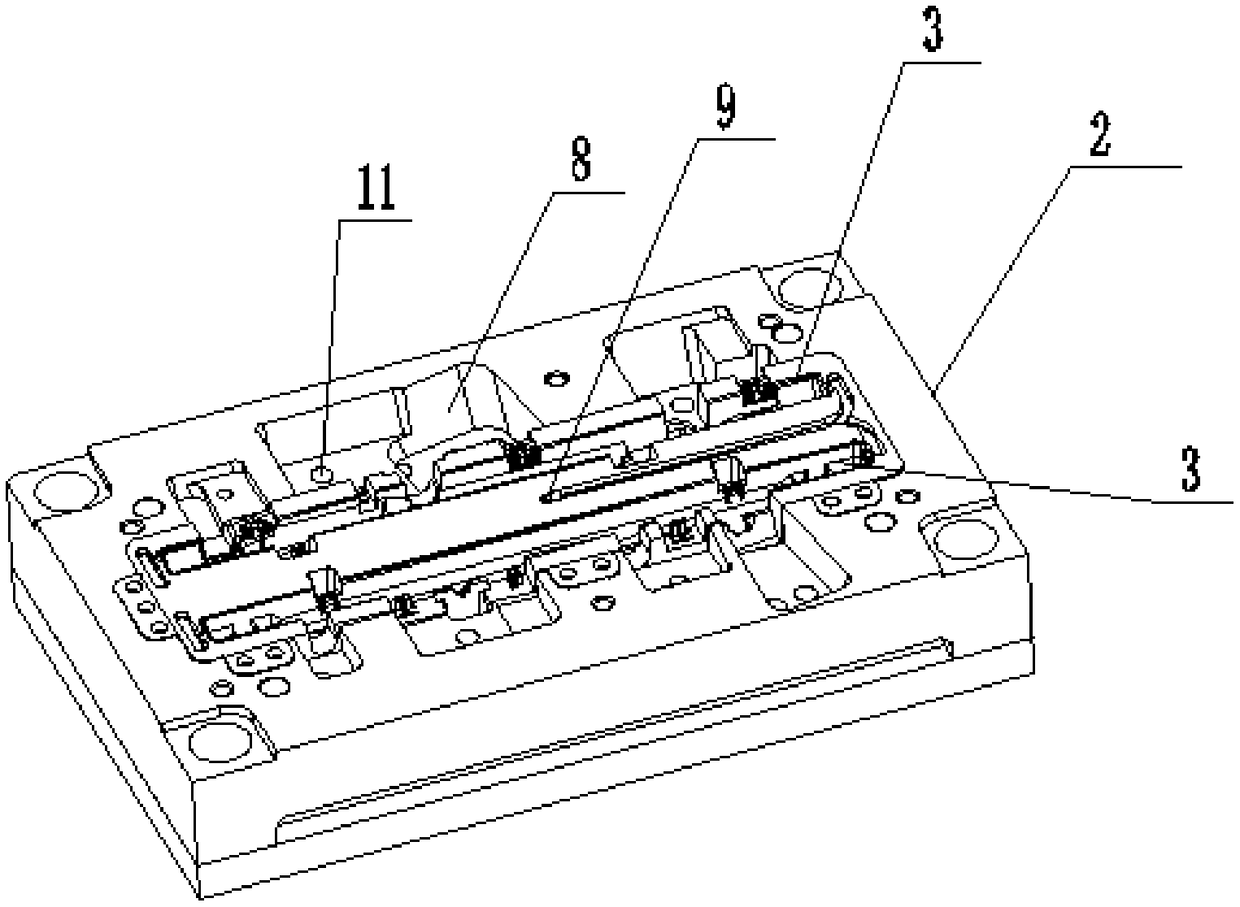

[0021] see Figure 1-6 , a multi-purpose radiator water chamber processing mold, comprising an upper mold 1 and a lower mold 2 cooperating with the upper mold 1, the lower mold 2 is provided with a detachable lower mold core 3, the upper mold The mold 1 is provided with a detachable upper mold core 4, and the lower mold 2 is provided with a plurality of sliders 5 that cooperate with the lower mold core 3 to prepare an interface accessory or a clamping accessory of the water chamber; The lower mold 2 is provided with a guide groove 6 that cooperates with the slider 5; the lower mold 2 is also provided with a plurality of fixed stations 7 for fixing the guide groove 6; the described guide groove 6 passes through a detachable fixed on the fixed station 7, each guide groove 6 corresponds to one to two fixed stations 7; the upper mold 1 is provided with a slider accommodation cavity 8, and the lower mold core 3, The upper mold core 4 and the slider 5 enclose a cavity for forming a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com