A thermal error prediction method for ball screw feed system of CNC machine tool

A technology of ball screw and feed system, which is applied in the direction of metal processing machinery parts, metal processing equipment, maintenance and safety accessories, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The technical solution will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0068] A thermal error prediction method for a ball screw feed system of a CNC machine tool, comprising the following steps:

[0069] Step 1, ball screw feed system temperature measurement

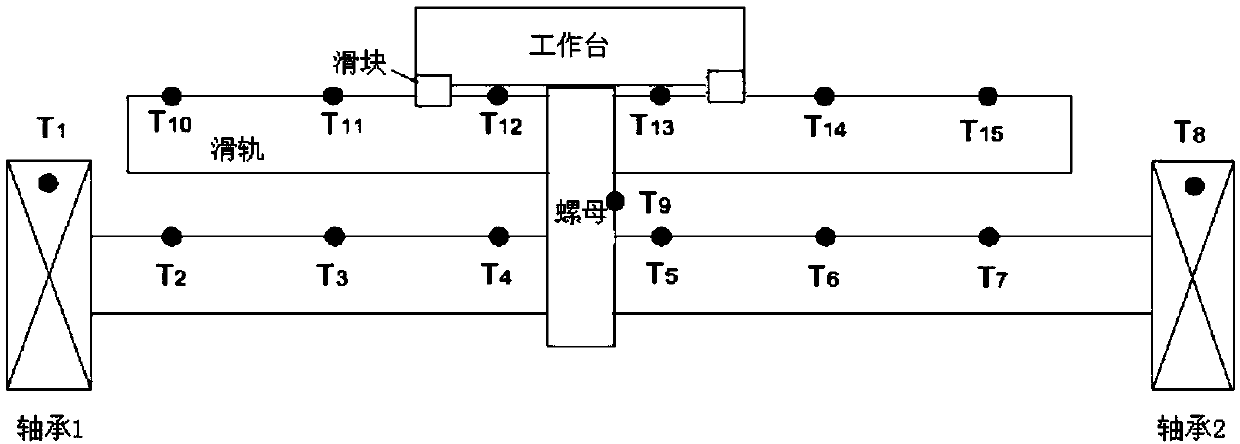

[0070] Determine the surface temperature detection point of the feeding system, such as figure 1 shown. Among them, T1 and T8 are the surface points of the two screw support bearings, T9 is the surface point of the nut flange; the rest are evenly distributed on the surface of the guide rail on the side of the screw shaft, such as T2-T7 and T10-T15. Fix three T-type patch thermocouples at points T1, T8 and T9 with a magnetic base, and a laptop computer performs continuous sampling with a sampling period of 20s. Use a high-precision infrared measuring instrument to perform timing detection on measurement points T2-T7 and T10-T15.

[0071] Step 2, estab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com