Extruding device for mechanical part machining

A technology for extrusion devices and mechanical parts, applied in length measuring devices, metal processing equipment, manufacturing tools, etc., can solve the problems of low processing efficiency, unfavorable maintenance, and single function, and achieve the effect of improving processing efficiency and facilitating timely maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing:

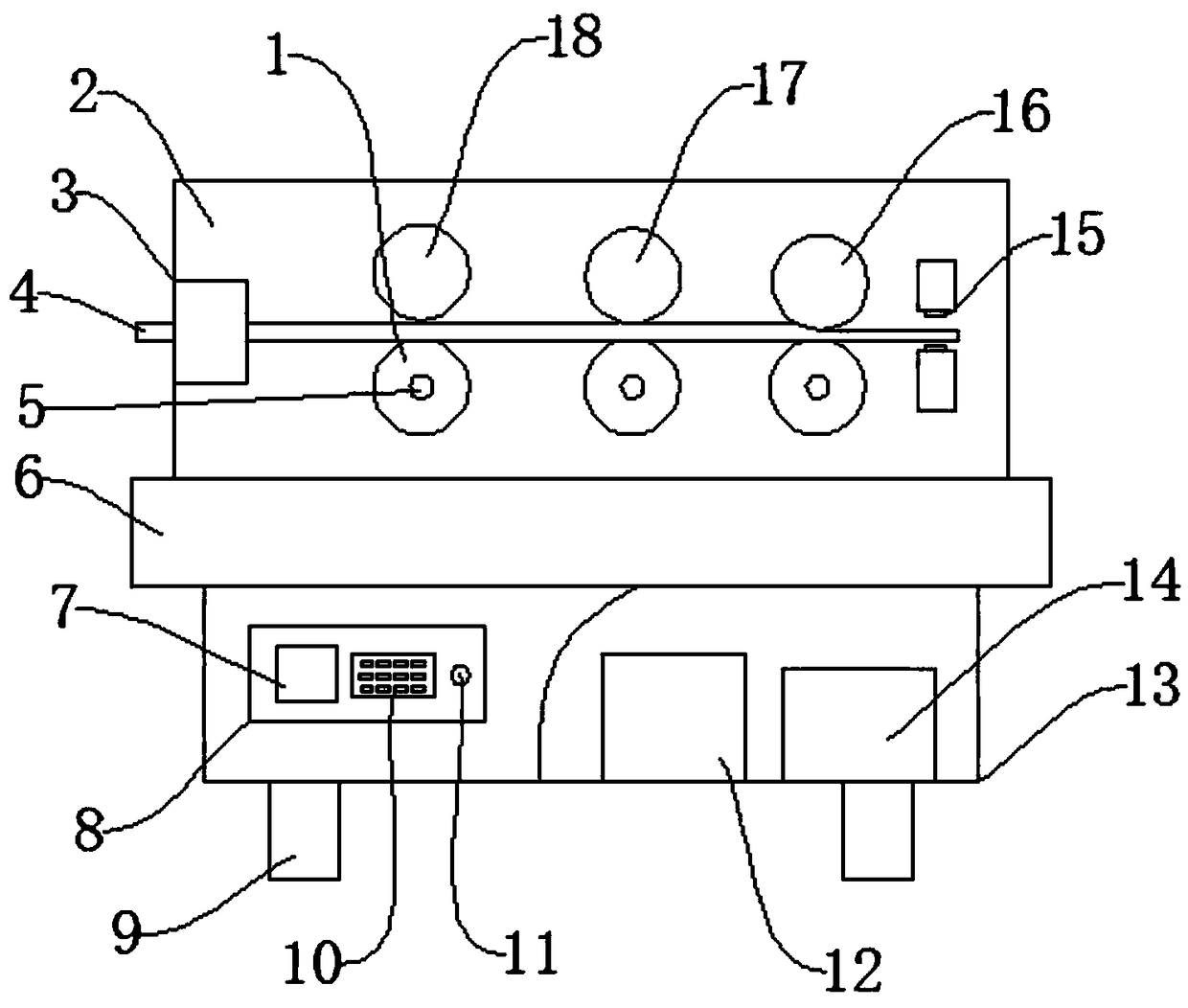

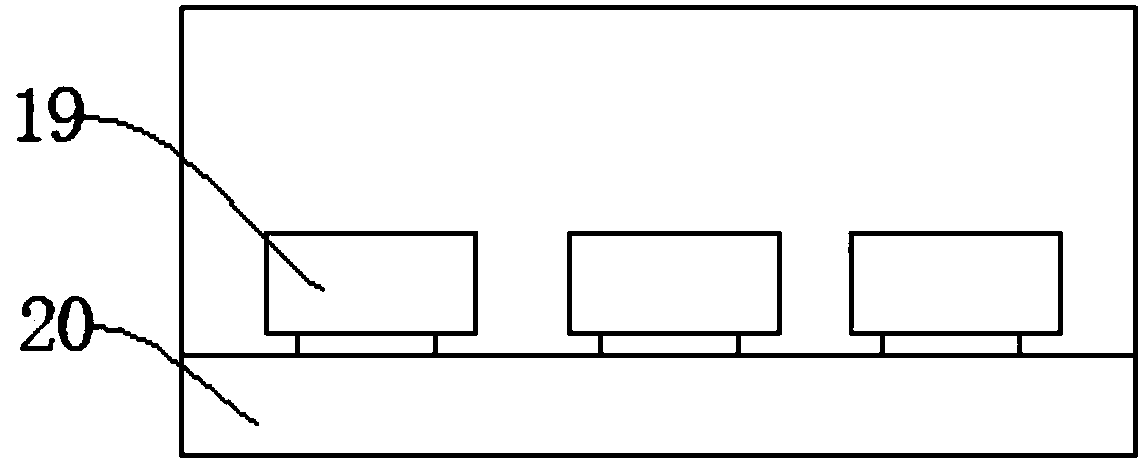

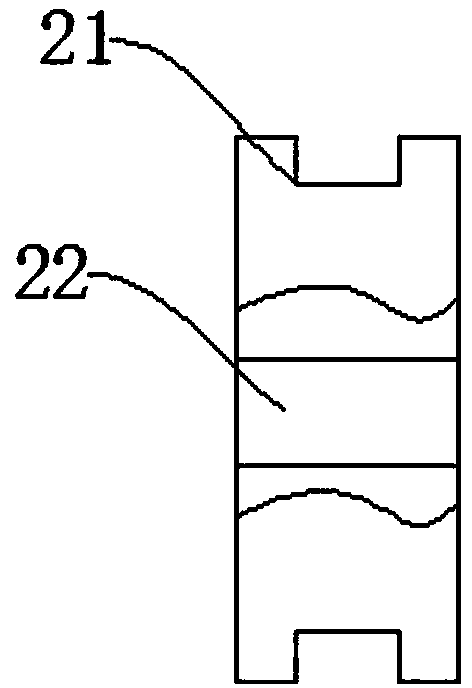

[0020] Such as Figure 1-Figure 3 As shown, an extrusion device for processing mechanical parts includes a cabinet 13 and a cabinet 2. Support legs 9 are provided at the four corners of the lower end of the cabinet 13, and the support legs 9 play a supporting role. An operation panel is provided on the upper side of the side wall of the cabinet 13. 8. The operation panel 8 plays a supporting role. The operation panel 8 is provided with a display screen 7, a keyboard 10, and a control knob 11. The inside of the cabinet 13 is provided with a power supply 14 and a controller 12. The upper end of the cabinet 13 is provided with a support platform 6 and a support platform 6. It plays a supporting role, and the upper middle part of the supporting platform 6 is provided with a chassis 2, and the chassis 2 plays a supporting role. A guide block 3 is arranged on the upper side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com