A steel slag advanced treatment process

An advanced treatment and steel slag technology, applied in grain treatment, cement production, etc., can solve the problem of comprehensive utilization of steel slag, etc., and achieve the effect of improving the comprehensive utilization value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

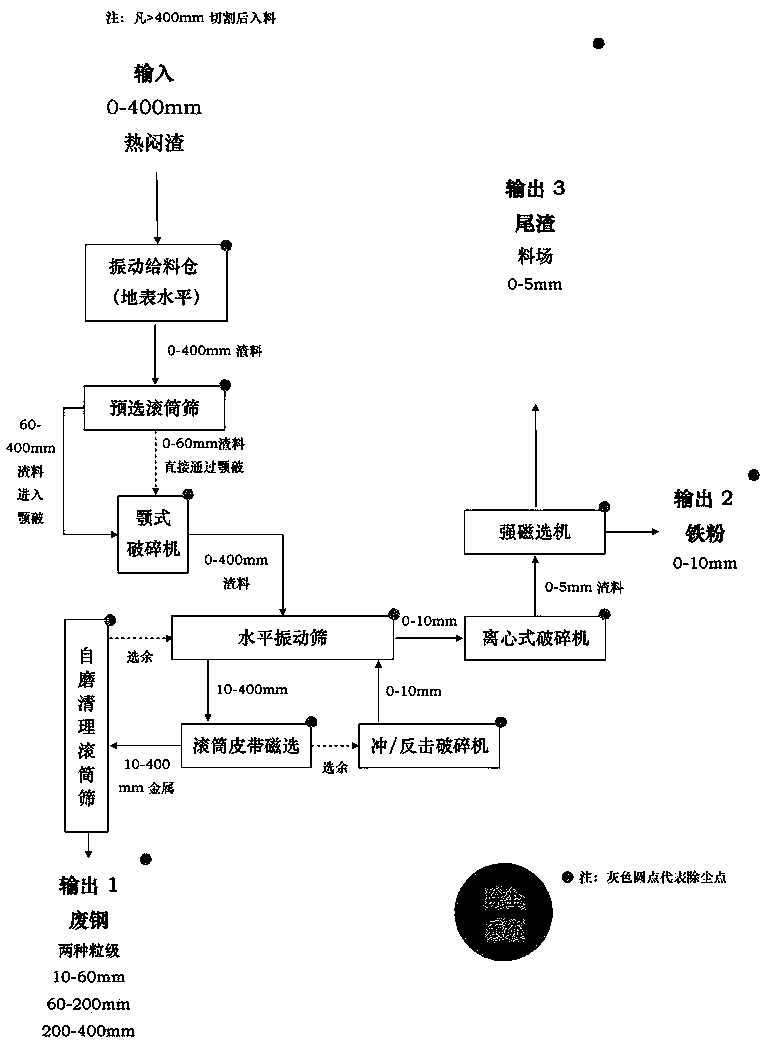

[0030] The steel slag advanced treatment process flow of the present embodiment is as follows figure 1 So, include the following steps:

[0031] 1) The stuffed steel slag is discharged by the excavator / crane, loaded onto the dump truck, transported to the raw material transfer station, and enters the vibrating feeding bin through the feeding platform.

[0032] 2) Vibrating feeding into the feeding bin, the diameter range of feeding is 0-400mm; the steel slag raw material transfer station above 400mm has a separate environmental protection dust removal pretreatment area, which is cut to below 400mm by oxygen and then processed online.

[0033] 3) Steel slag is divided into two types of 60~400mm and 0~60mm through the pre-selected trommel screen.

[0034] 4) Among them, the 60-400 mm steel slag is directly sent to the jaw crusher, and after crushing, it falls into the conveyor belt under the jaw crusher and is sent to the horizontal vibrating screen.

[0035] 5) Among them, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com