Processing device for organic fertilizer production

A technology for processing equipment and organic fertilizer, applied in the field of processing equipment for organic fertilizer production, can solve the problems of high labor intensity of workers, low production efficiency, cumbersome processing steps, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

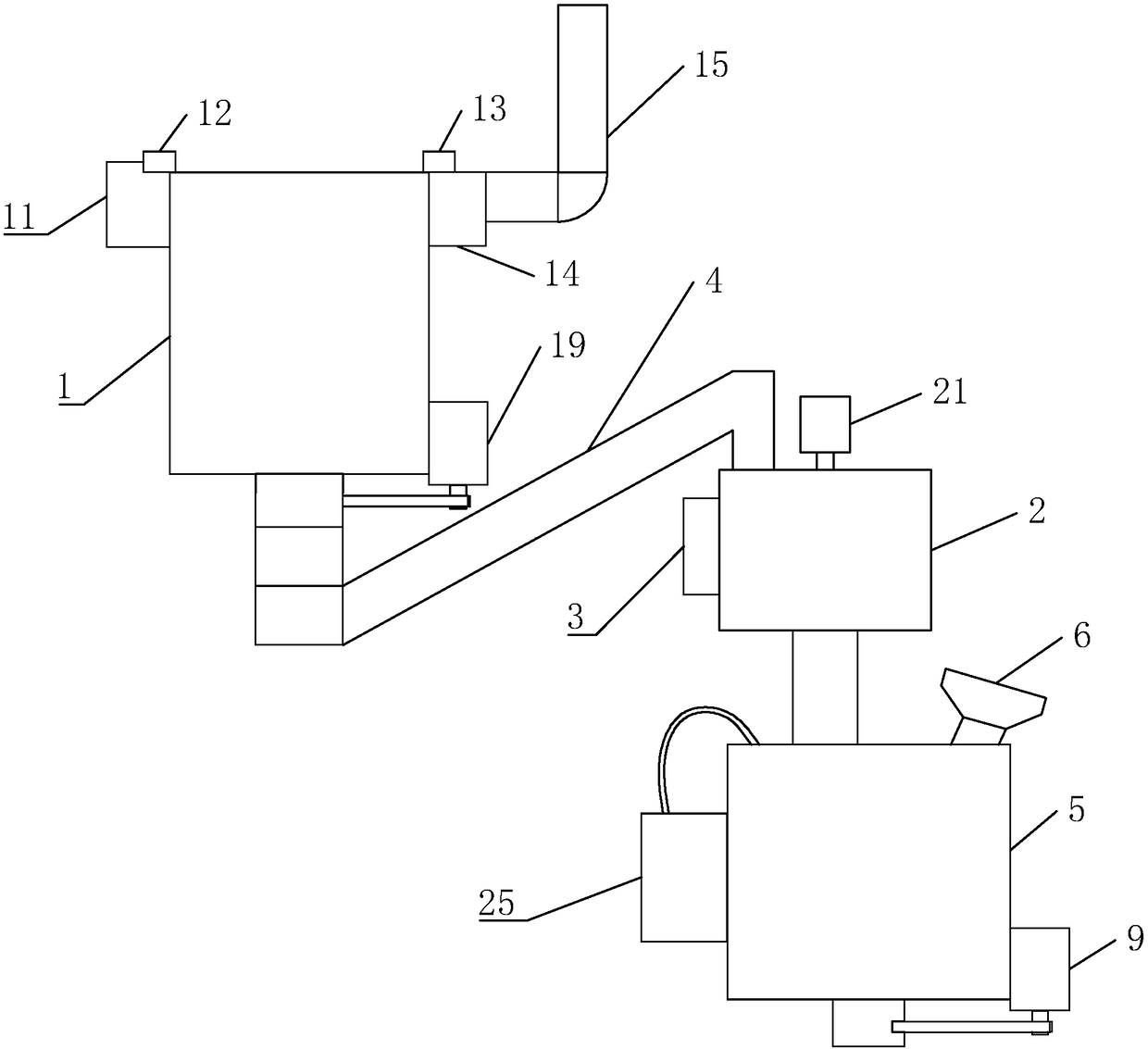

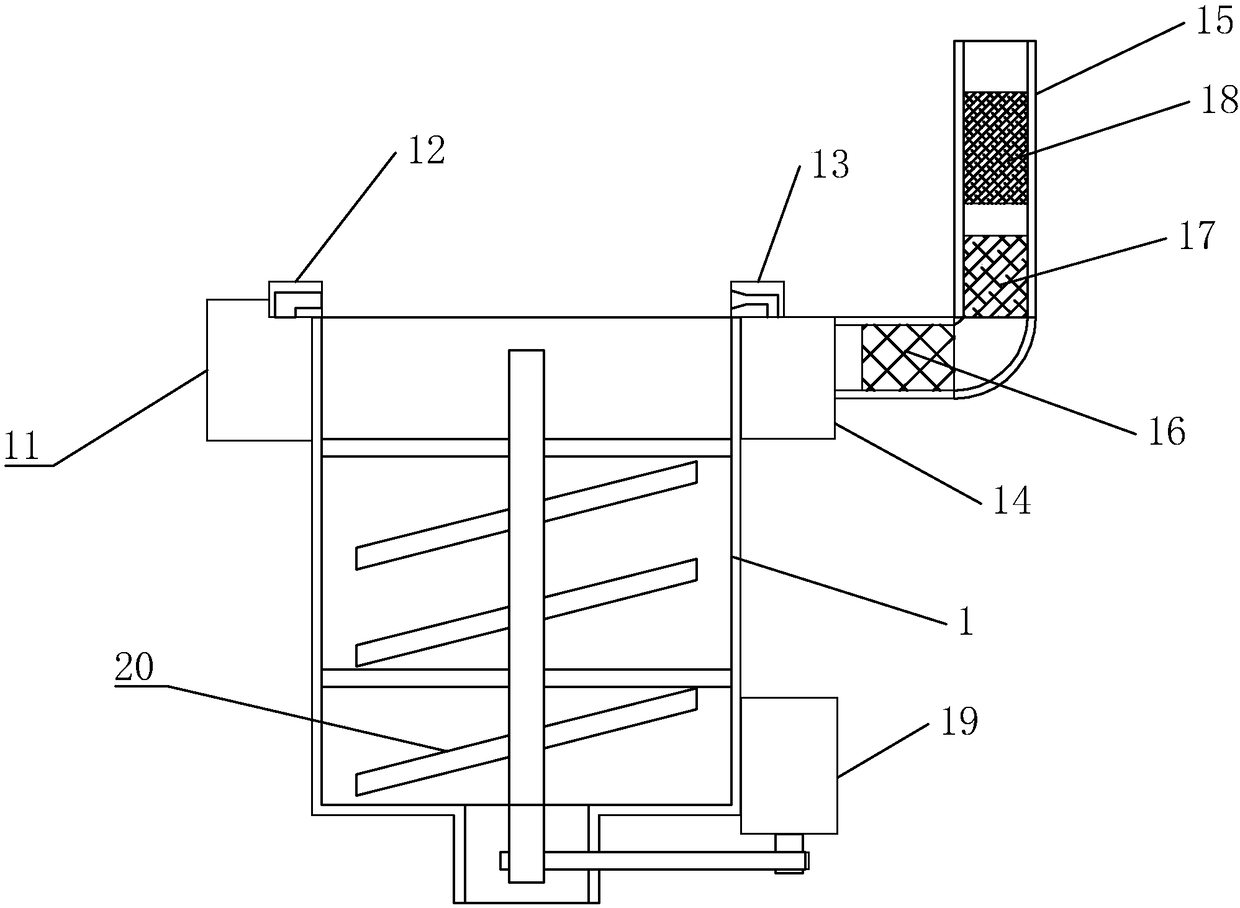

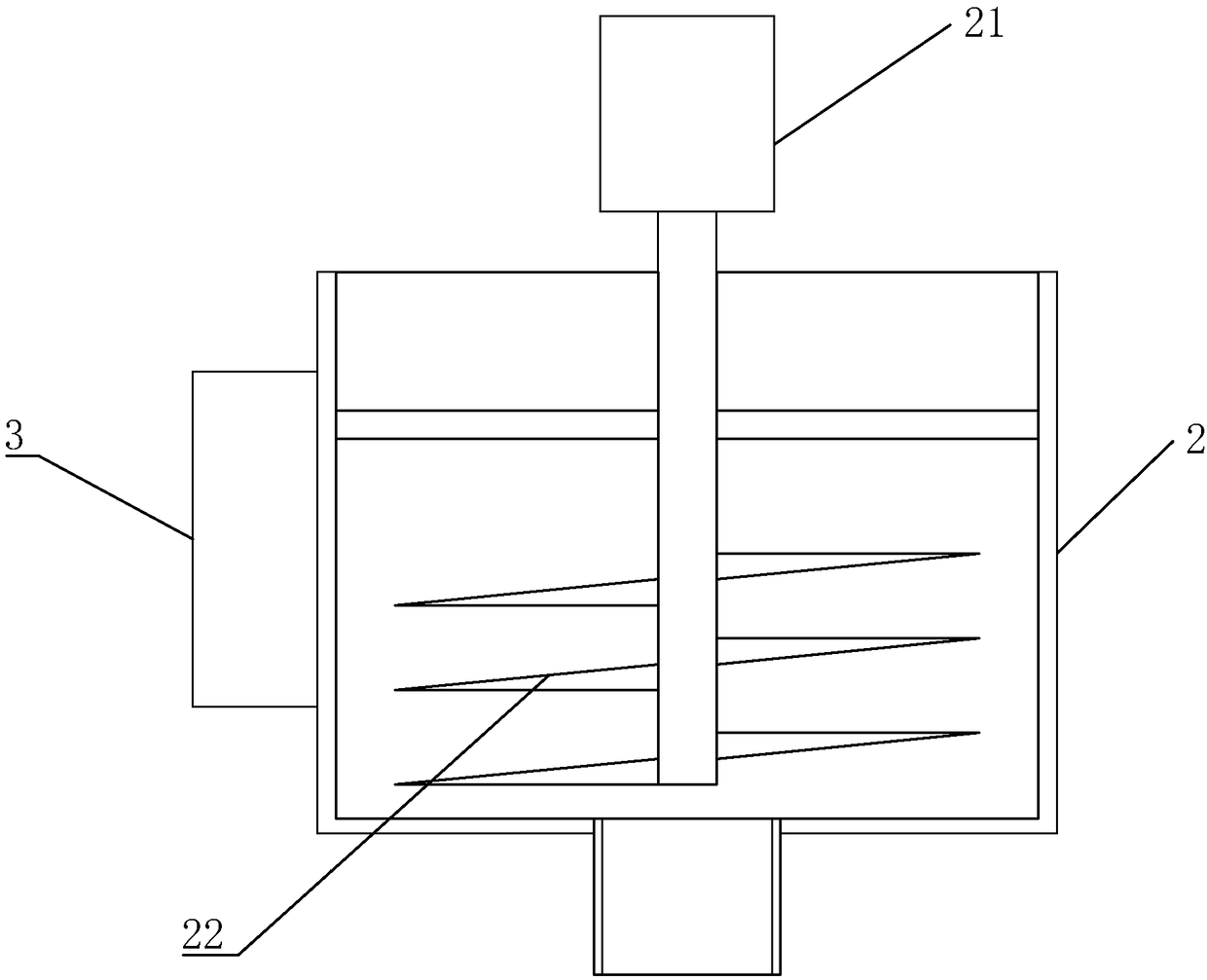

[0032] refer to Figures 1 to 4As shown, a processing equipment for organic fertilizer production in this embodiment includes a drying mechanism, a crushing mechanism and a mixing mechanism, and the drying mechanism includes an electric heating drying cylinder 1, a sealed wind shear mechanism and a stirring mechanism The upper end of the electric heating drying cylinder 1 is sealed with a sealed wind shear mechanism, the stirring mechanism is installed in the electric heating drying cylinder 1, and the crushing mechanism includes a crushing cylinder 2, a vibrating motor 3 and Pulverizing device, the feeding port of the pulverizing cylinder 2 and the electric heating drying cylinder 1 are connected with a conveying auger 4, the vibration motor 3 is arranged on the outer wall of the pulverizing cylinder 2, and the pulverizing device is arranged on the pulverizing In the barrel 2, the mixing mechanism includes a mixing barrel 5, a feed hopper 6, a first stirring paddle 7, a secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com