Universal hoisting equipment for transformer substation overhauling

A technology for hoisting equipment and substations, which is applied in the direction of hoisting devices, transportation and packaging, and load hanging components, etc. It can solve the problems of limited space between substations, difficulties in handling and assembling up and down, and heavy lifting equipment, etc. Assembling at any place, preventing falling or breakage of porcelain pillars, and reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

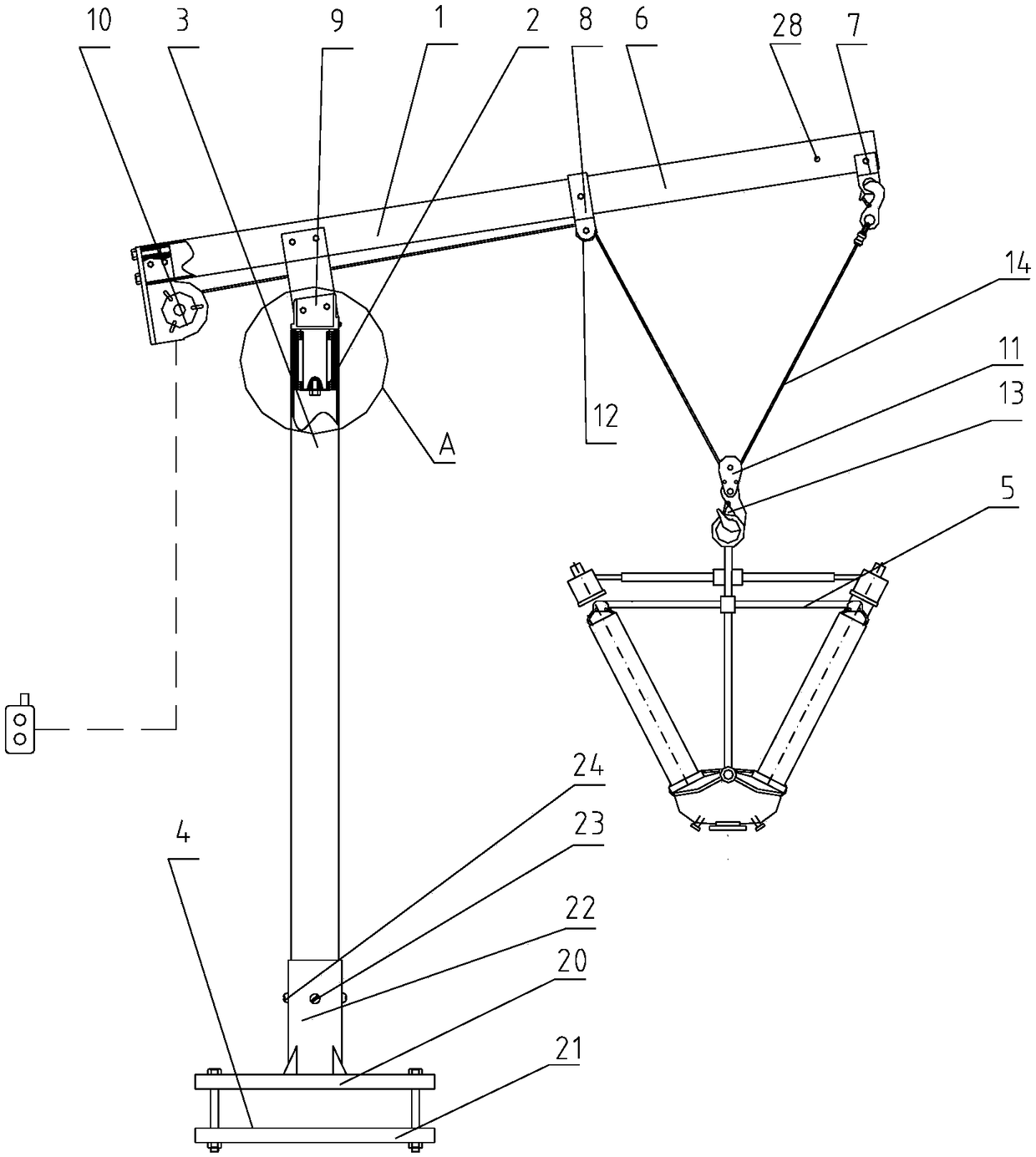

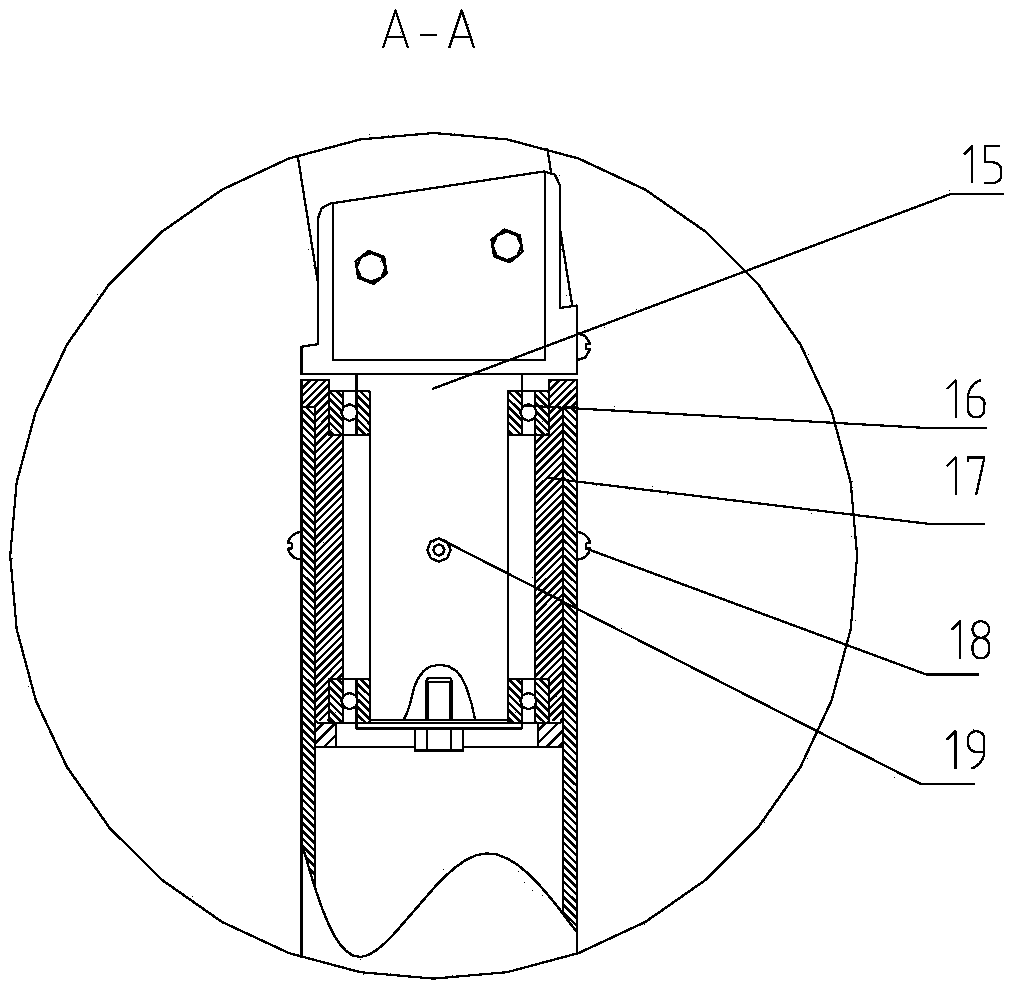

[0032] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0033] Such as figure 1 As shown, a general lifting equipment for substation maintenance includes a lifting device 1, a rotating device 2, a column 3 and a base 4, and also includes a special lifting device 6 for a disconnector. The hoisting device 1, rotating device 2, upright column 3, base 4 and special spreader 6 for isolating switch are split structures, which can be transported separately and assembled on site. The column 3 is installed on the base 4, the rotating device 2 is installed on the column 3, the hoisting device 1 is installed on the rotating device 2, and the hoisting device 1 can rotate 360° horizontally around the axis of the column 3.

[0034] The hoisting device 1 includes the boom 6 and the front hook frame 7, the movable pulley frame 8, the swivel frame 9 and the hoisting hoist 10 fixed on the boom 6 by bolts in the front a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com