Anti-loose roller cloth guide-unfolding stacking device

A fabric and loose technology, applied in the direction of winding strips, thin material handling, folding thin materials, etc., can solve the problem of single structure of the fabric guiding device, achieve better stacking effect, good continuity, and improve guiding efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

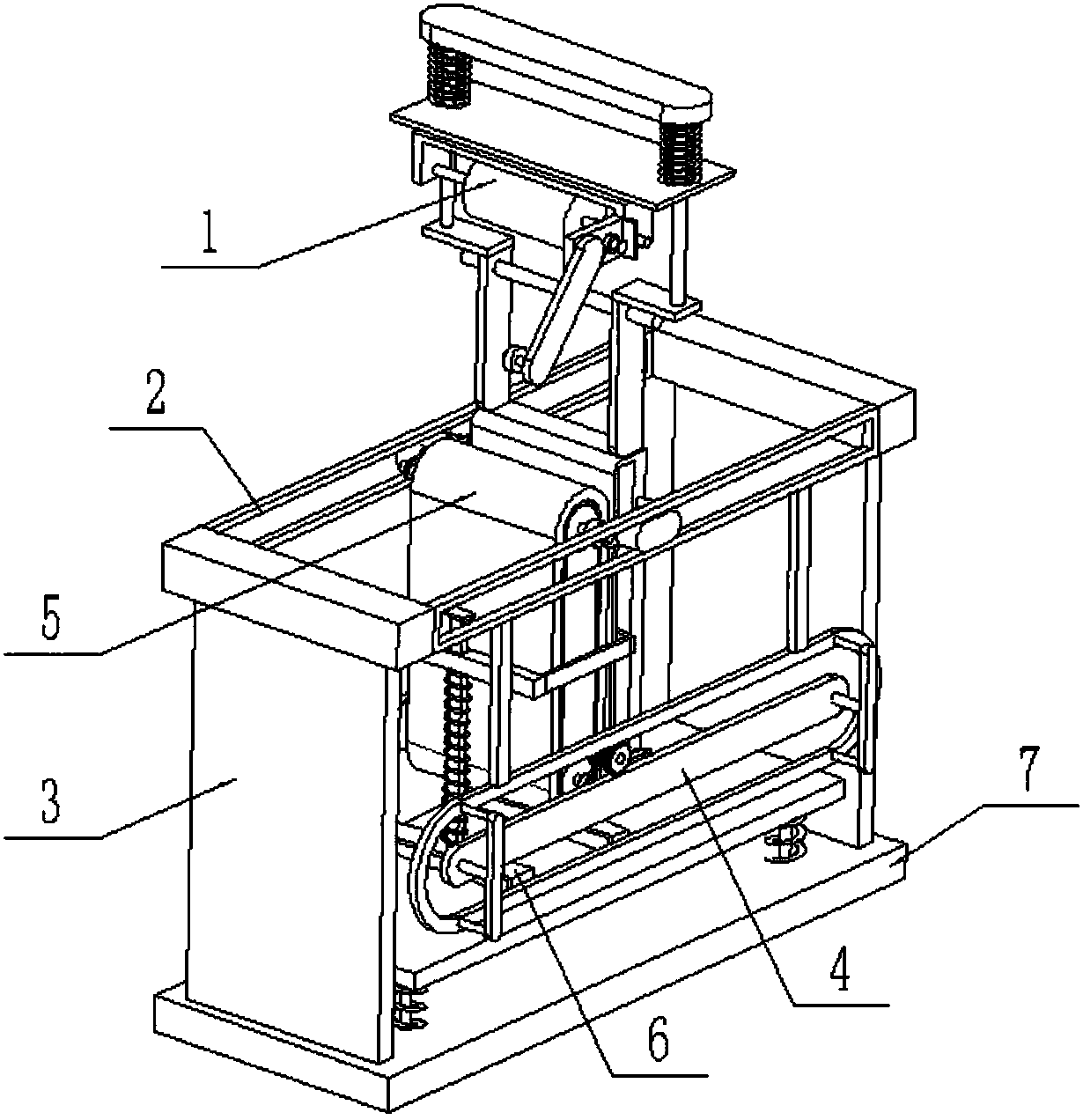

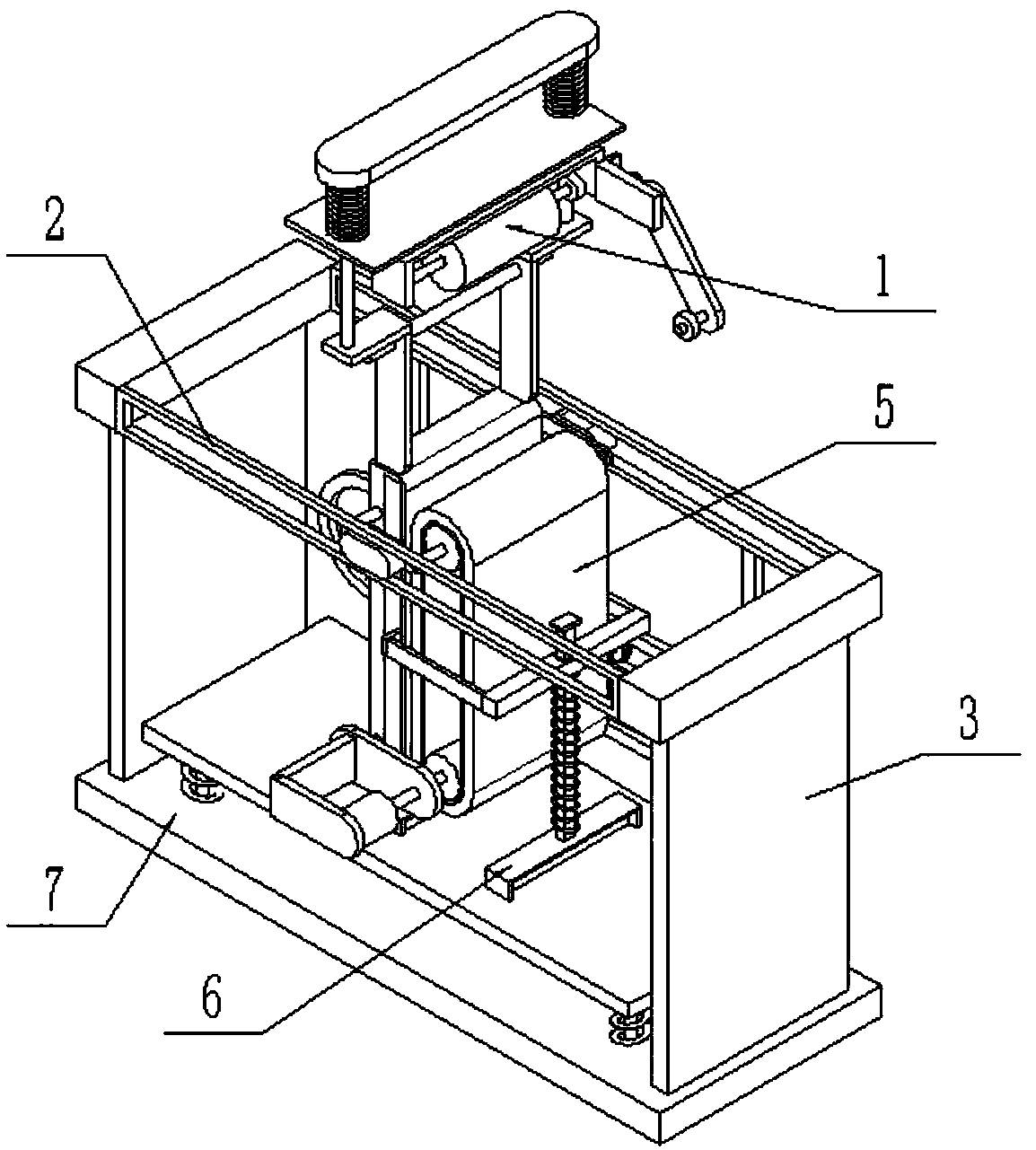

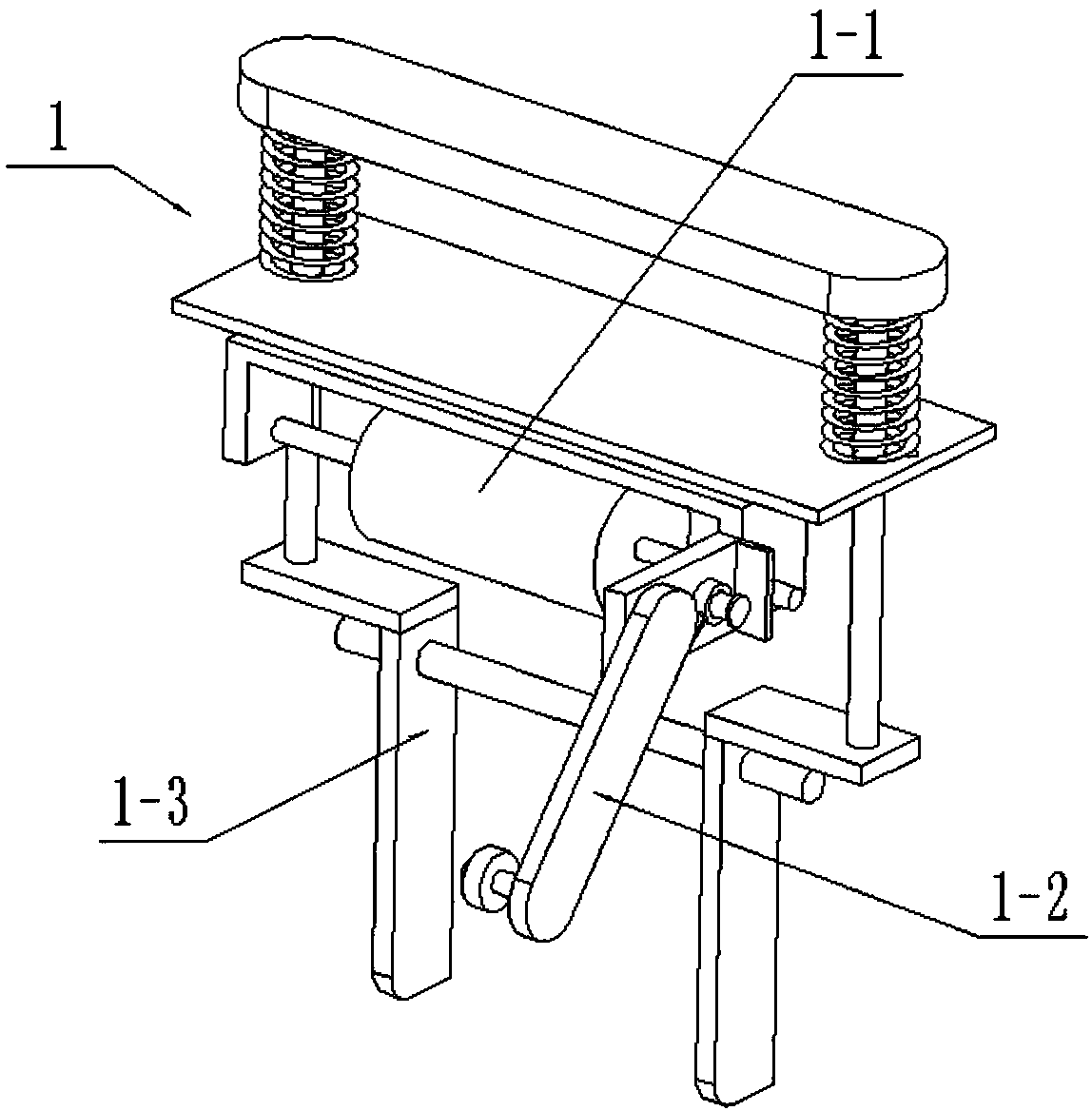

[0036] Such as Figure 1-16 As shown, an anti-loose roll cloth guiding and stacking device includes an anti-loosening cloth guiding assembly 1, an upper sliding frame assembly 2, a support plate 3, a lower sliding frame assembly 4, a cloth guiding mechanism 5, and a cloth press The flat mechanism 6 and the cloth laying platform assembly 7, the anti-loose cloth guide assembly 1 is connected to the upper end of the cloth guiding mechanism 5; the two sides of the bottom end of the upper sliding frame assembly 2 are respectively fixedly connected with a support plate 3, two The bottom end of the support plate 3 is fixedly connected to both sides of the top of the cloth laying platform assembly 7; the lower sliding frame assembly 4 is fixedly connected to the front side of the bottom end of the upper sliding frame assembly 2; the front side of the cloth guiding mechanism 5 The upper end of the sliding frame assembly is connected to the front end of the upper sliding frame assembly ...

specific Embodiment approach 2

[0040] Such as Figure 1-16 As shown, the upper sliding frame assembly 2 includes a left horizontal column 2-1, a right horizontal column 2-2, a front rectangular chute plate 2-3 and a rear rectangular chute plate 2-4; the left horizontal column 2- The front and rear ends of the right side of 1 are respectively fixedly connected to the front rectangular chute plate 2-3 and the rear rectangular chute plate 2-4; the front rectangular chute plate 2-3 and the rear rectangular chute plate 2-4 The right end is fixedly connected to the front and rear ends of the left side of the right cross column 2-2.

[0041] The lower sliding frame assembly 4 includes a rectangular support rod 4-1, an outer chute plate 4-2, an inner chute plate 4-3 and a connecting plate frame 4-4; the top end of the outer chute plate 4-2 is fixedly connected Two rectangular support bars 4-1, the upper ends of the two rectangular support bars 4-1 are fixedly connected to the lower end of the front rectangular chu...

specific Embodiment approach 3

[0042] Such as Figure 1-13As shown, the cloth guiding mechanism 5 includes a drive motor 5-1, a cloth guiding roller assembly 5-2, an auxiliary cloth pressing block assembly 5-3, a front sliding block 5-4, a rear sliding block 5-5, a front The connecting plate 5-6, the rear connecting plate 5-7 and the traction gear assembly 5-8; the upper end of the front side of the cloth guiding roller assembly 5-2 is rotationally fitted and connected to the left end of the front sliding block 5-4, and the cloth guiding The upper end of the rear side of the opening roller assembly 5-2 is rotatably connected to the left end of the rear sliding block 5-5, and the lower end of the front side of the cloth guide roller assembly 5-2 is rotatably connected to the left end of the front connecting plate 5-6. The lower end of the rear side of the cloth guide roller assembly 5-2 is rotatably connected to the left end of the rear connecting plate 5-7; -4 and the front connecting plate 5-6, the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com