Production process and production device of a non-closed covered rubber tube

A technology of production process and production device, which is applied in the field of production process and production device of non-closed clad rubber tube, and can solve the problems of inability to achieve non-closure and inability to achieve sealing effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The production process of a non-closed sheathed rubber tube of the present embodiment comprises the following steps

[0032] A. Extrude the rubber raw material into a non-closed ring-shaped rubber tube with a mold provided with a spiral rubber extrusion port;

[0033] B. Set a powder injection port in the gap between the adjacent tube walls of the ring-shaped rubber tube, and the powder spray port sprays powder, so that a powder interlayer is formed between the adjacent tube walls of the ring-shaped rubber tube;

[0034] C. The ring-shaped rubber tube with powder interlayer is formed by vulcanization device;

[0035] D. The ring-shaped rubber tube formed by the vulcanization device passes through the normal temperature circulating water tank, washes away the powder interlayer, and cools down to shape at the same time;

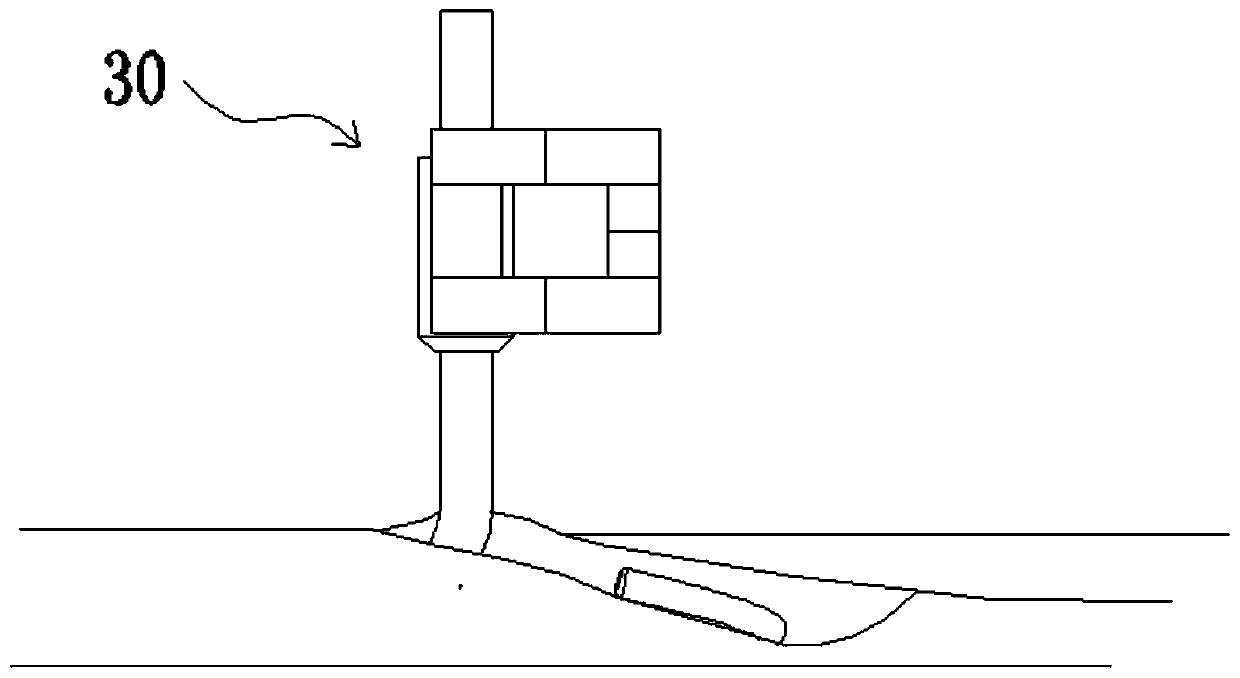

[0036] E. The ring-shaped rubber tube after cooling and shaping passes through the turning device, and the rubber tube wall covered in the outer layer ...

Embodiment 2

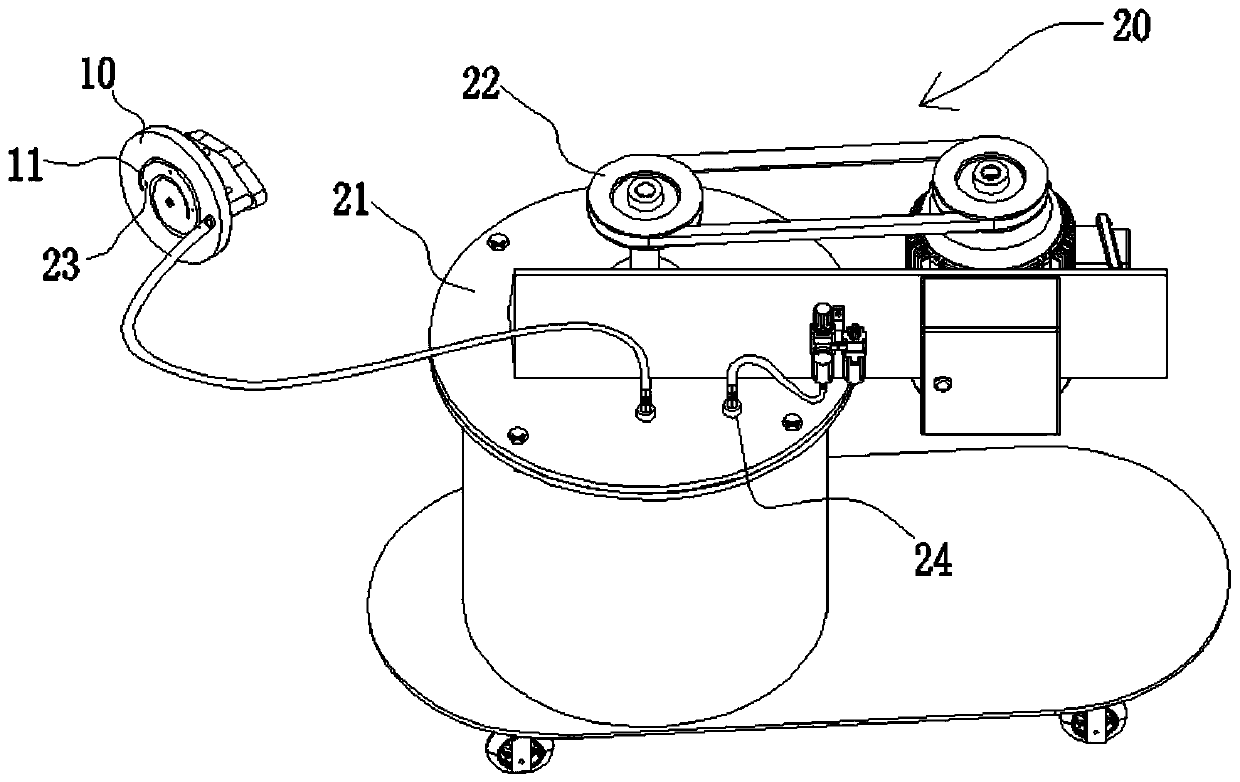

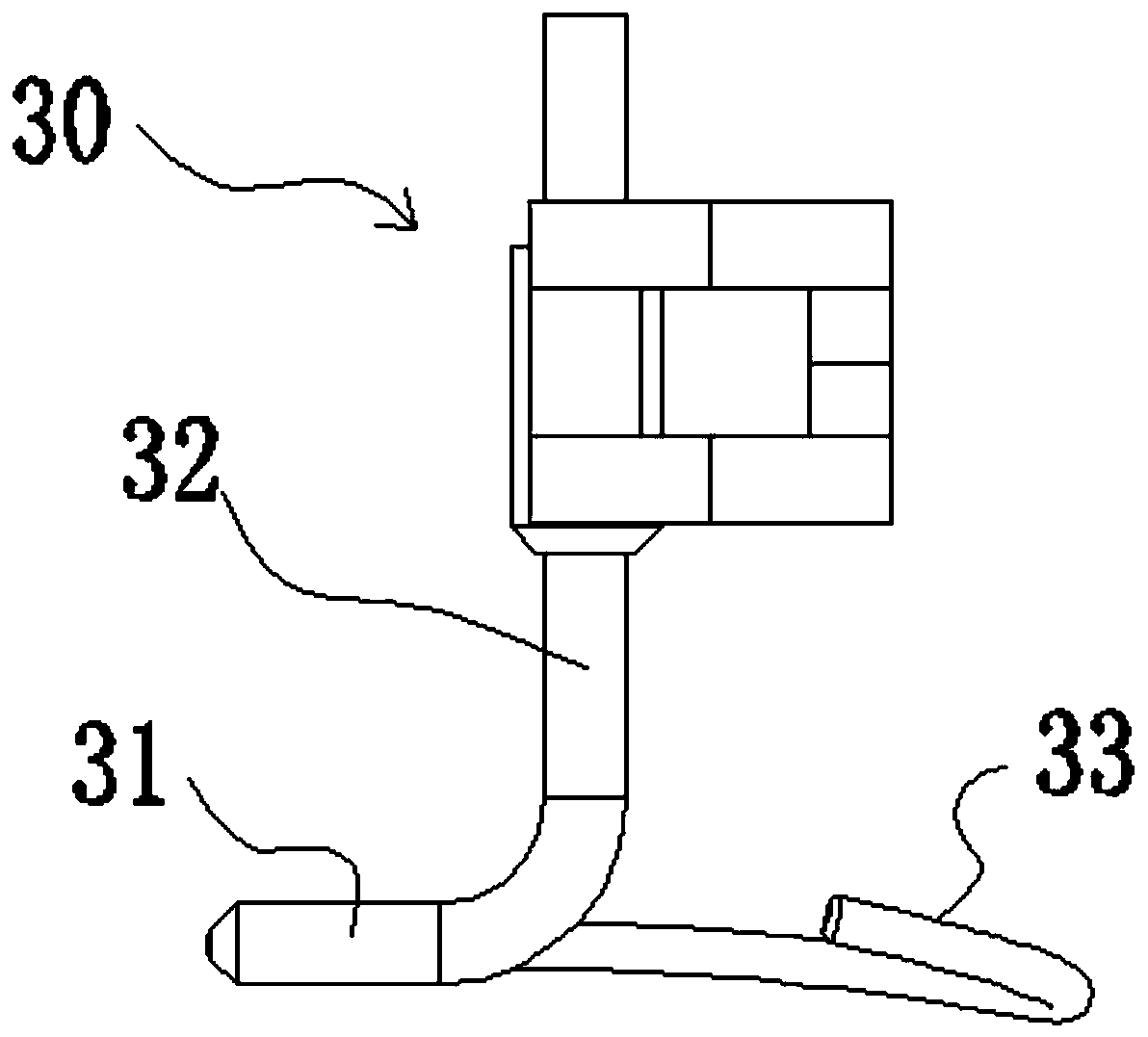

[0045] Such as figure 1 , 2 , 3, and 4, the production device of a non-closed sheathed rubber tube of the present embodiment includes an extrusion die 10, a powder spraying device 20, a vulcanizing device, a normal temperature cooling water tank, a mouth turning device 30, and a pressing device connected in sequence. tightening device and heating and baking setting device, the extrusion die 10 is provided with a spiral rubber extrusion port 11; the powder spraying device 20 includes a powder storage box 21, a powder lifter 22 and a powder outlet 23. Powder is stored in the powder storage box 21, and the powder lifter 22 is connected to the powder outlet 23, and the powder outlet 23 is set in the gap between the spiral rubber extrusion port 11 on the extrusion die 10; The mouth introversion device 30 includes a deflector 31, an opening standpipe 32 and an introversion device 33, and the introversion device 33 is provided with a downward bending part. The powder storage box 21...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com