Bipolar magnetic material and manufacturing method thereof

A technology of magnetic material and production method, applied in the direction of magnetic material, magnetic object, inorganic material magnetism, etc., can solve the problems such as the magnetic strip cannot be moved casually, the magnetic performance of the magnet is degraded, and the magnetic performance cannot be realized, so as to overcome the weak adsorption, The effect of small fluctuation of suction power, smooth movement and rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

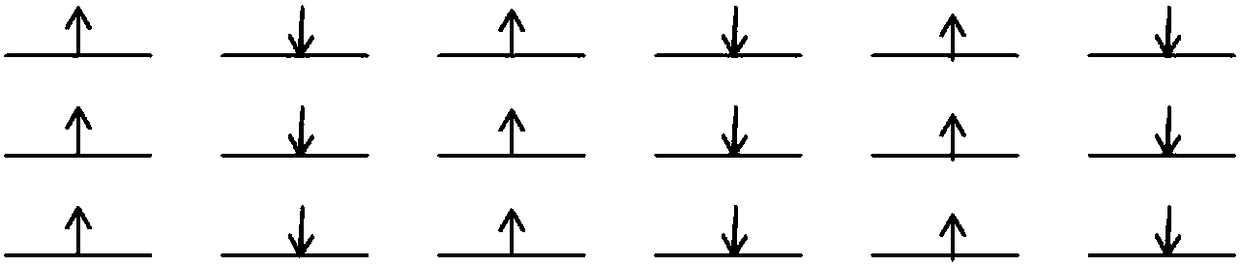

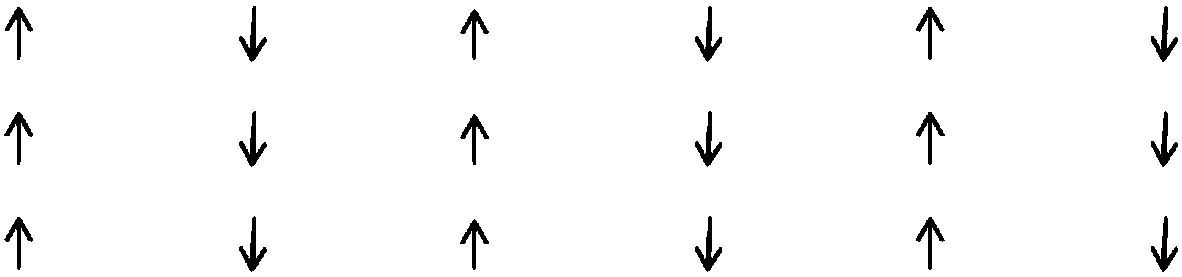

[0049] Refer to the attached figure 1 . An amphoteric magnetic object, comprising a high molecular polymer filled with a magnetic material, which is composed of the components shown in Table 1.

[0050] The raw material composition of table 1 embodiment 1

[0051] raw material

[0052] The production steps are as follows:

[0053] Banbury mixing: The materials are mixed according to the formula, and the rubber is mixed with an internal mixer, and the clinker is discharged after the rubber mixing temperature reaches 120-150 °C.

[0054] Open mixing: Use the open mixing machine to mix the mixed materials again.

[0055] Refining and crushing: Use the internal mixer to re-refine the smelted film into small lumps and then use the crusher to crush.

[0056] Calendering: The crushed pellets are directly calendered with a calender, and samples with thicknesses of 0.3mm, 0.5mm, 0.6mm, 0.8mm and 1.0mm are processed respectively.

[0057] Magnetization: Each model is line...

Embodiment 2

[0073] Refer to the attached figure 1 . An amphoteric magnetic object, comprising a high molecular polymer filled with a magnetic material, which is composed of the components shown in Table 4.

[0074] The raw material composition of table 4 embodiment 2

[0075] raw material

[0076] The production steps are as follows:

[0077] Banbury mixing: The materials are mixed according to the formula, and the rubber is mixed with an internal mixer, and the clinker is discharged after the rubber mixing temperature reaches 120-150 °C.

[0078] Open mixing: Use the open mixing machine to mix the mixed materials again.

[0079] Refining and crushing: Use the internal mixer to re-refine the smelted film into small lumps and then use the crusher to crush.

[0080] Calendering: The crushed pellets are directly calendered with a calender, and samples with thicknesses of 0.6 mm, 0.7 mm, 0.8 mm and 1.0 mm are processed respectively.

[0081] Magnetization: each sample is linear...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com