Low-cycle reciprocating test device for concrete member

A low-cycle reciprocating and testing device technology, used in measuring devices, using repetitive force/pulse force to test material strength, instruments, etc., can solve problems such as fatigue of concrete structures, maintain stability, avoid lateral overturning, improve safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

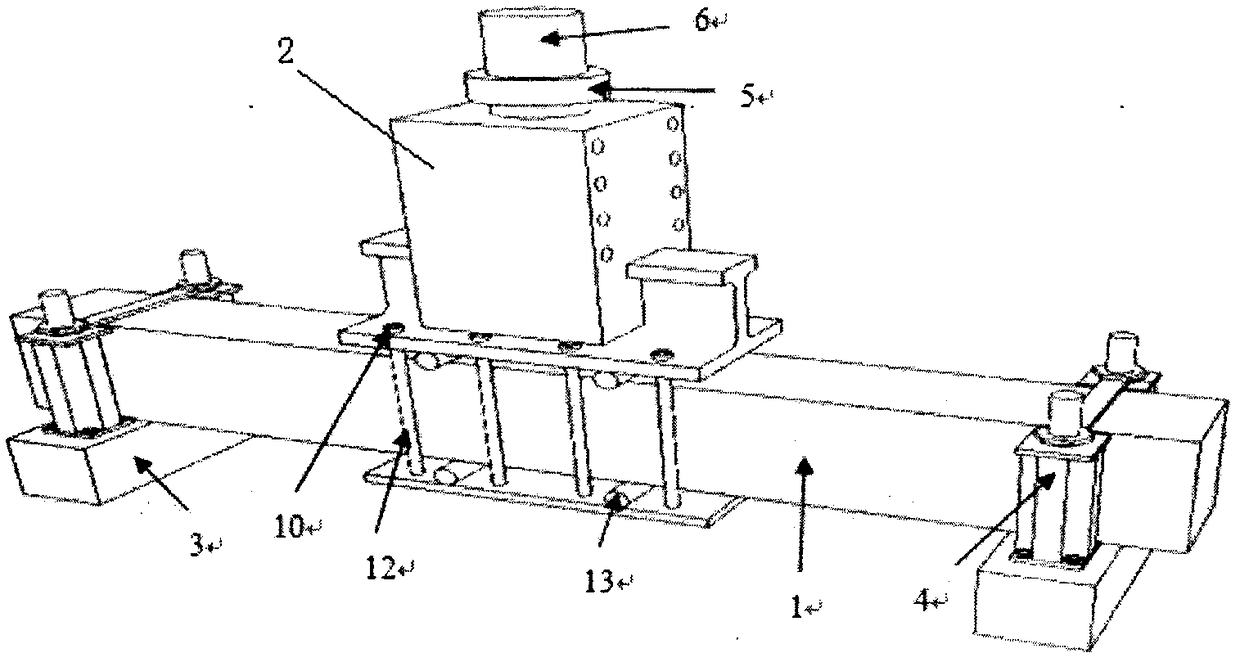

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and implementation examples.

[0019] The invention is a low-cycle reciprocating test device for concrete specimens with simple structure design, easy operation, no influence on other functions of the existing test equipment after disassembly, and good practicability.

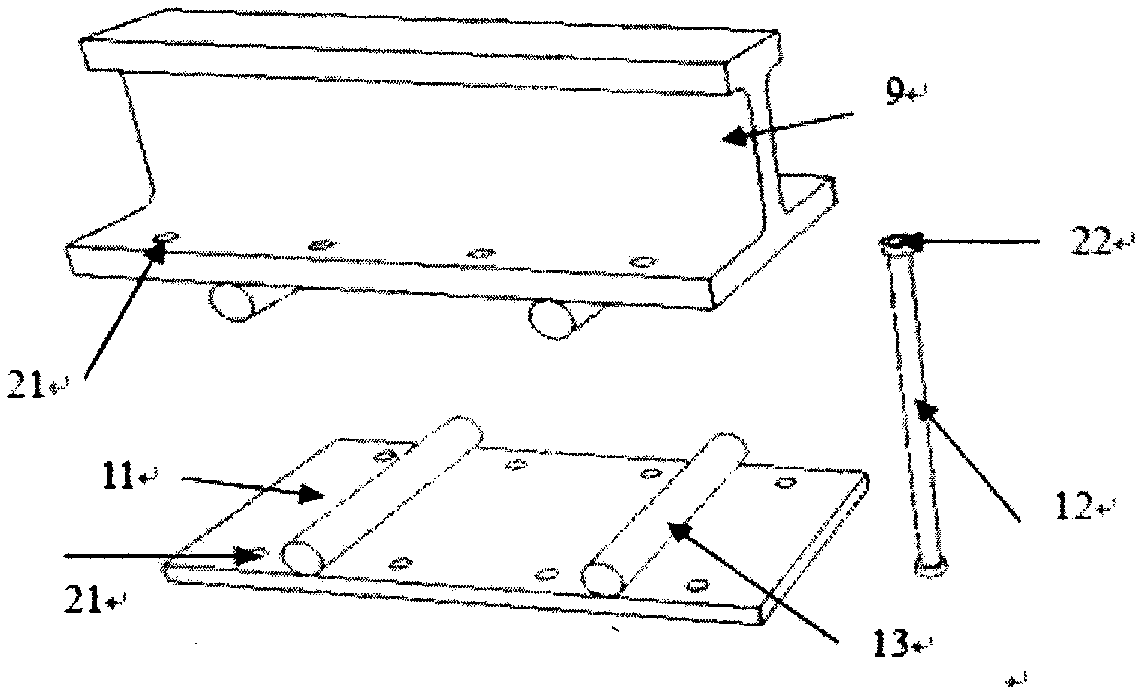

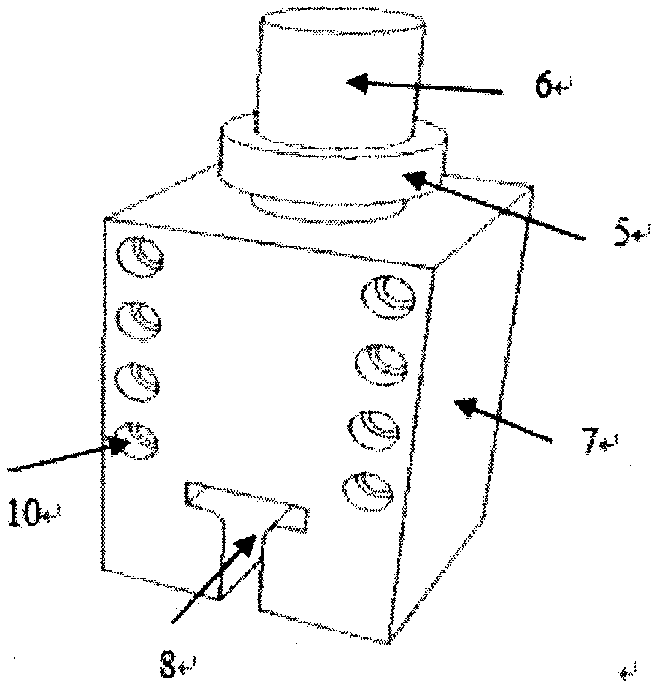

[0020] It is mainly composed of concrete specimens, fixtures, bases, rigid supports and other parts. The clamp includes a pin, a first screw, and a steel plate. There is a T-shaped hole in the middle of the lower part of the steel plate for connecting the distribution beam at the lower part. Eight first anchor bolts are provided on both sides of the steel plate to improve the firmness of the entire clamp. The distribution beam and the lower steel sheet are connected by 8 second screw rods, and two cylindrical first anchors are respectively arranged between the distribution beam, the lower steel p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com