High-precision light control method for LED lights

A technology of LED lamps and LED lamp beads, which is applied to light sources, optical elements used to change the spectral characteristics of emitted light, electric light sources, etc., can solve the problems of poor control accuracy and prone to misoperations, and achieve the goal of not being prone to misoperations , the effect of high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

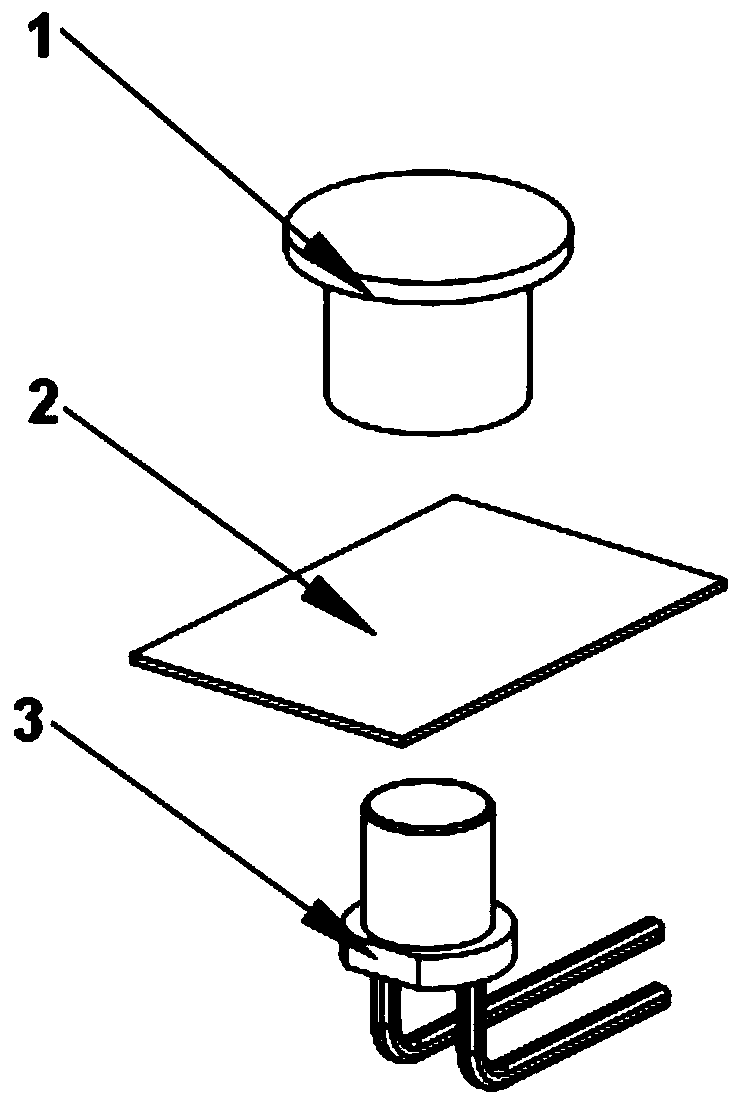

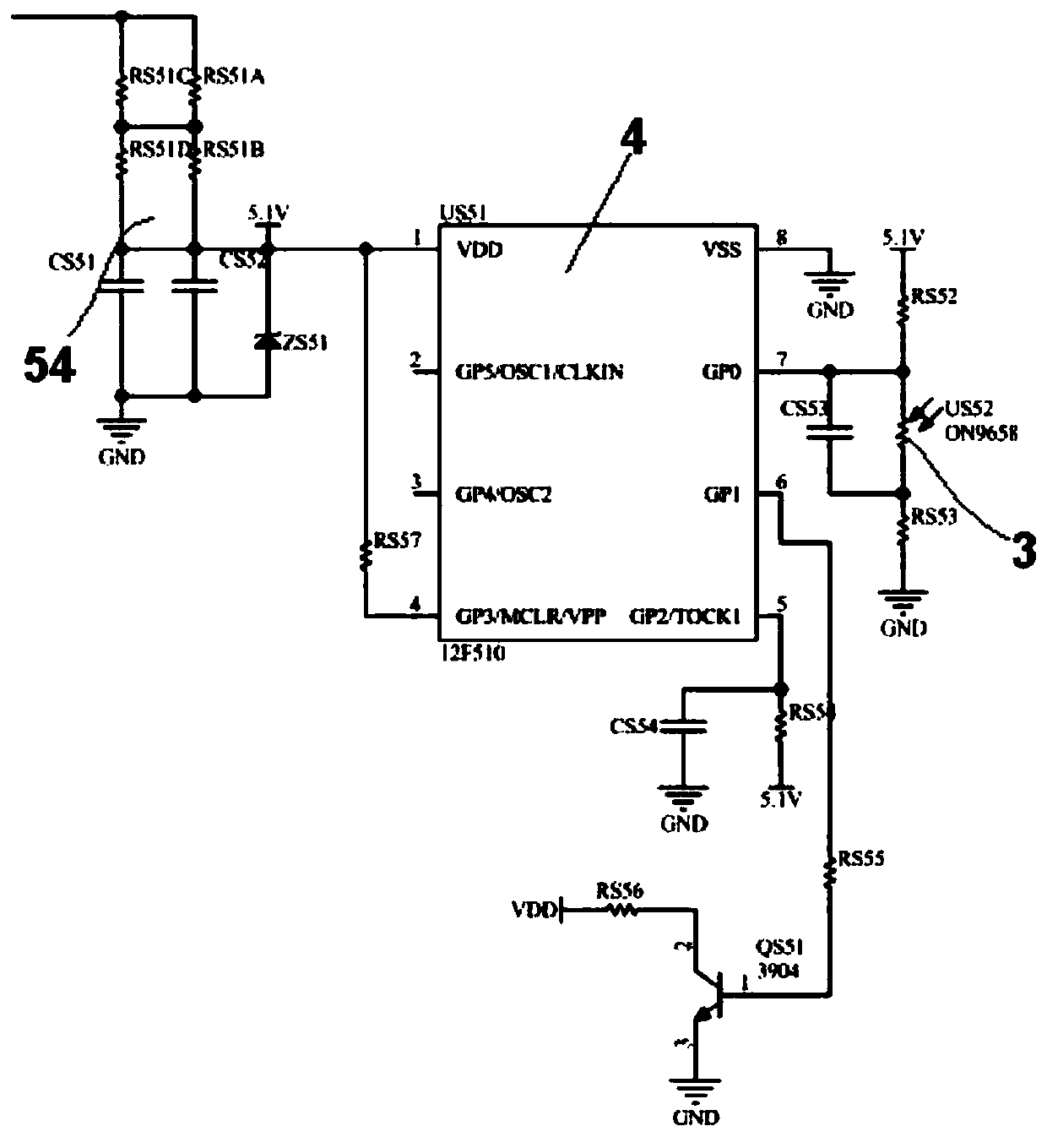

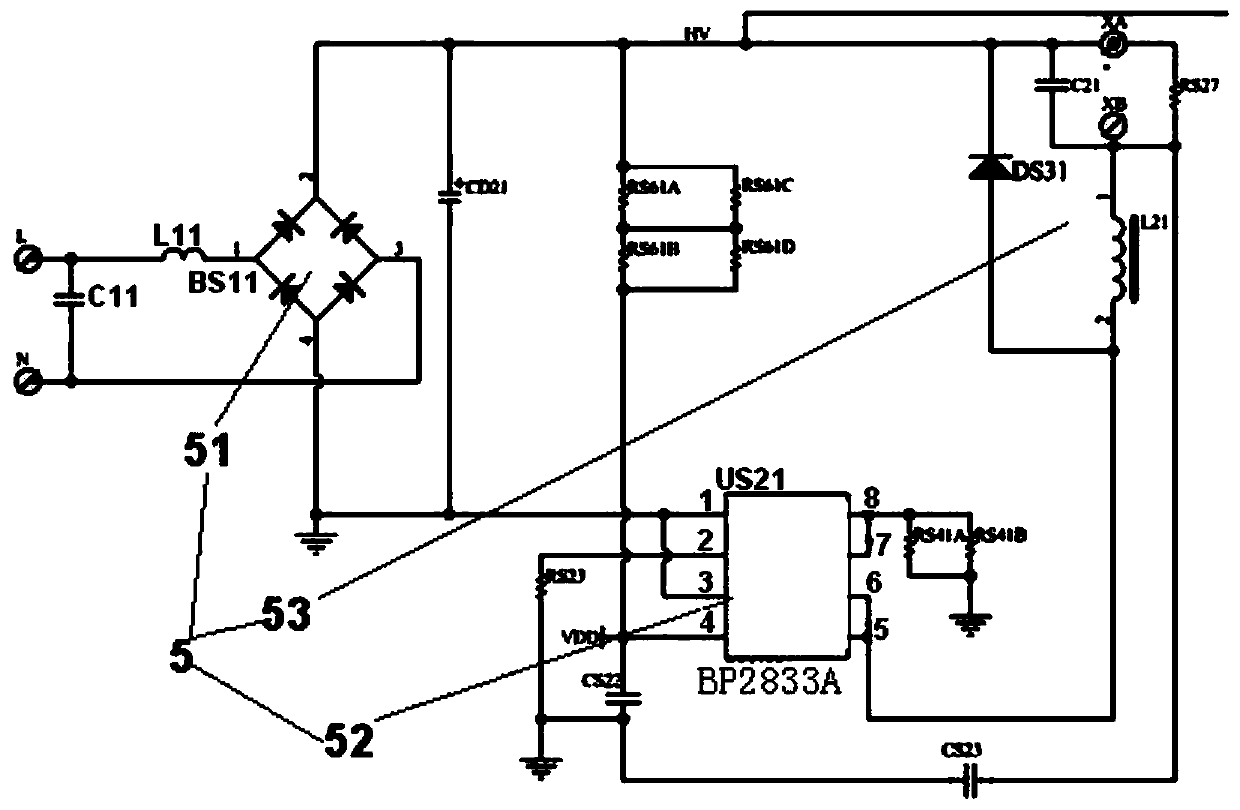

[0036] Such as figure 1 A high-precision light control method for an LED lamp is shown, including a visible light illuminance sensor 1, a filter 2 arranged on the probe of the visible illuminance sensor, a cosine corrector 3 connected to the filter, a single chip 4, and a drive circuit 5 and 20 LED lamp beads; the single-chip microcomputer is electrically connected to the visible light sensor and the driving circuit, and the driving circuit is electrically connected to each LED lamp bead; the probe of the visible light sensor is connected to the filter, and the filter is connected to the cosine corrector ; including the following steps:

[0037] Step 100, the single-chip microcomputer stores a comparison table of the illuminance voltage value and the illuminance value, the visible light sensor detects the illuminance voltage value of the envir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com