Assembly type wall with ventilation and air exchange functions and application thereof

A prefabricated and wall technology, applied in building components, buildings, building structures, etc., can solve problems such as inability to achieve energy saving, loss of thermal insulation advantages, poor ventilation effect, etc., to improve ventilation and air exchange effects, and improve temperature insulation Energy-saving effect, effect of stabilizing indoor temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1 Assembled wall with ventilation function

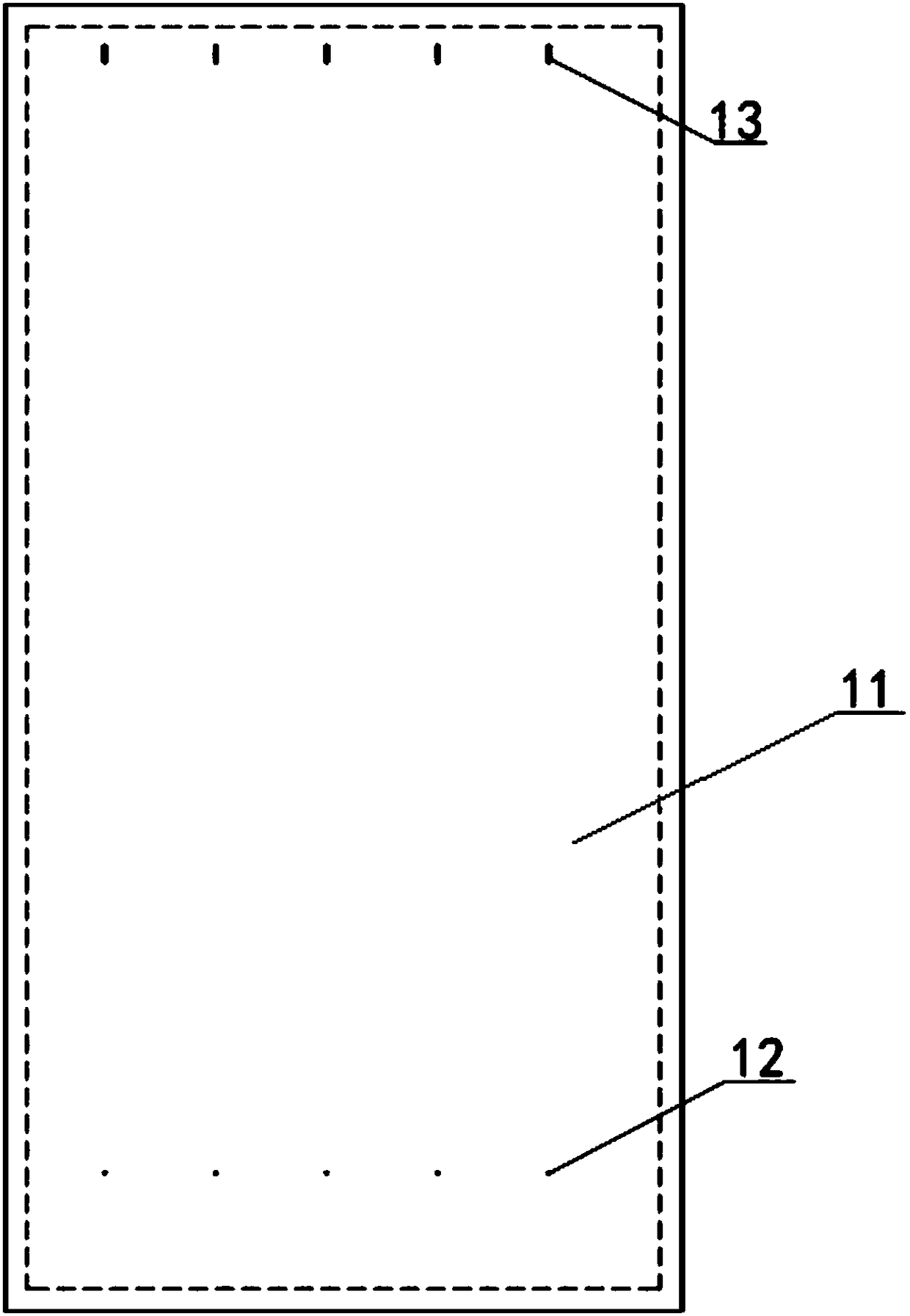

[0025] figure 1 , figure 2 A prefabricated wall with a ventilation function according to Embodiment 1 of the present invention is schematically shown. Such as figure 1 , figure 2 As shown, the assembled wall is provided with a cavity 11, the inner wall of the wall (i.e., the side near the room) is provided with a first through hole 12, and the outer wall of the wall (i.e., the side near the outdoor) is provided with a first through hole 12. There is a second through hole 13, and the cavity 11, the first through hole 12 and the second through hole 13 communicate with each other.

[0026] One or more first through-holes 12 may be provided. In this embodiment, multiple first through-holes 12 are preferably arranged at a certain distance laterally at the end of the inner wall of the wall body close to the ground. The spacing and quantity of the holes can be determined according to the requirements of the house f...

Embodiment 2

[0033] Embodiment 2 is used for the method for building indoor replacement fresh air

[0034] In this embodiment, the method for replacing fresh air indoors in a building includes: setting a cavity 11 in any wall of the building, and setting and opening a first through hole at an end of the inner wall of the wall close to the ground at a certain distance in the transverse direction. 12. Set up a second through hole 13 at a certain distance laterally at the end of the outer wall of the wall away from the ground, and make the cavity 11, the first through hole 12, and the second through hole 13 communicate with each other; wherein, the second through hole 13 is an oblique opening from bottom to top, and a filter membrane for filtering air is provided in the cavity 11 . When there is a temperature difference between the inside and outside of the building, the air outside the building flows into the building through the second through hole 13, the cavity 11, and the first through h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com