A steerable forklift

A technology for lifting forklifts and lifting slide rails, which is applied to lifting devices, safety devices of lifting equipment, etc., can solve the problems of inability to judge the status of goods in time, the need to repeatedly open and close attachments, and low operation efficiency, so as to improve the flexibility of use. , The effect of easy loading and unloading, easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

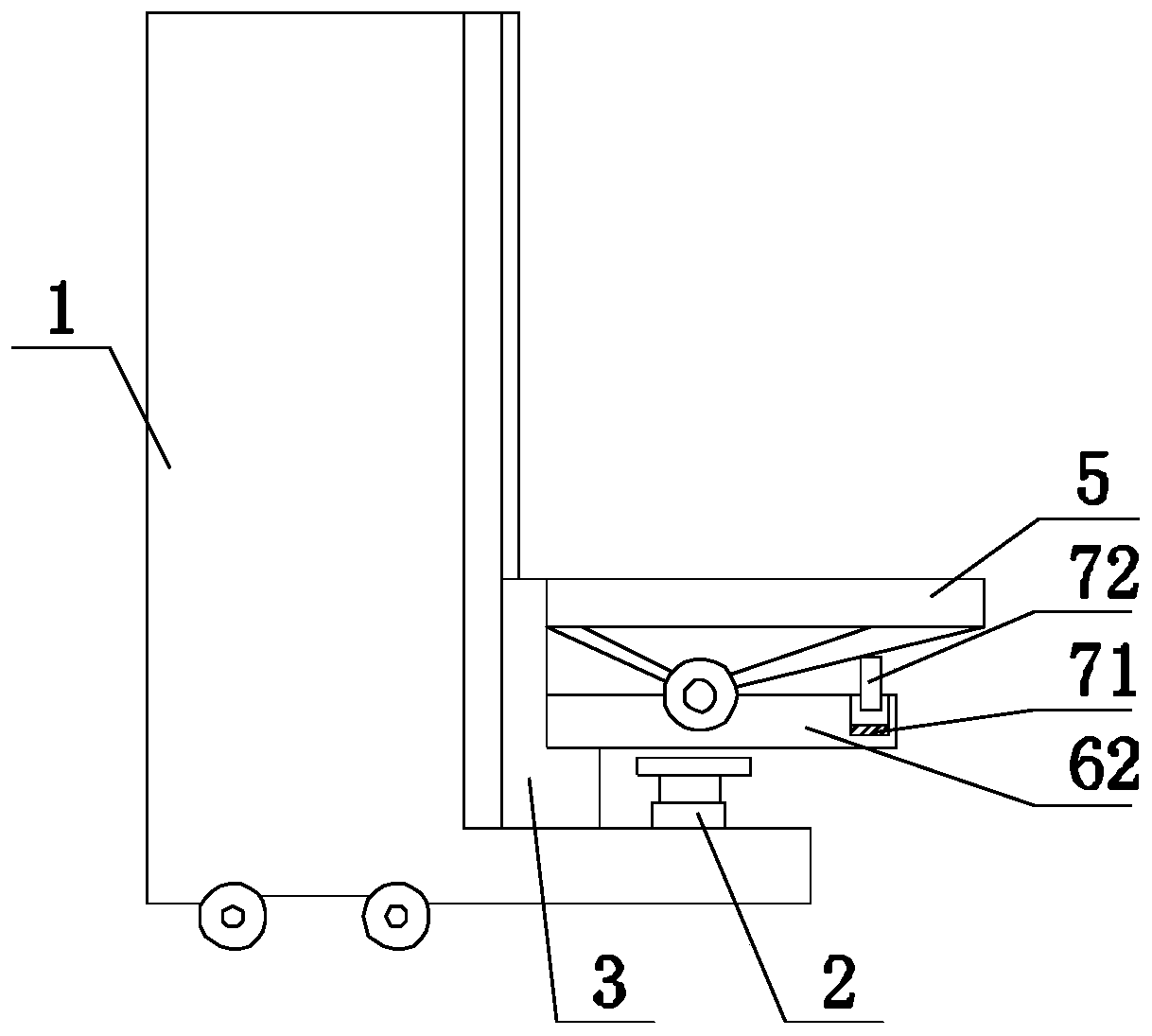

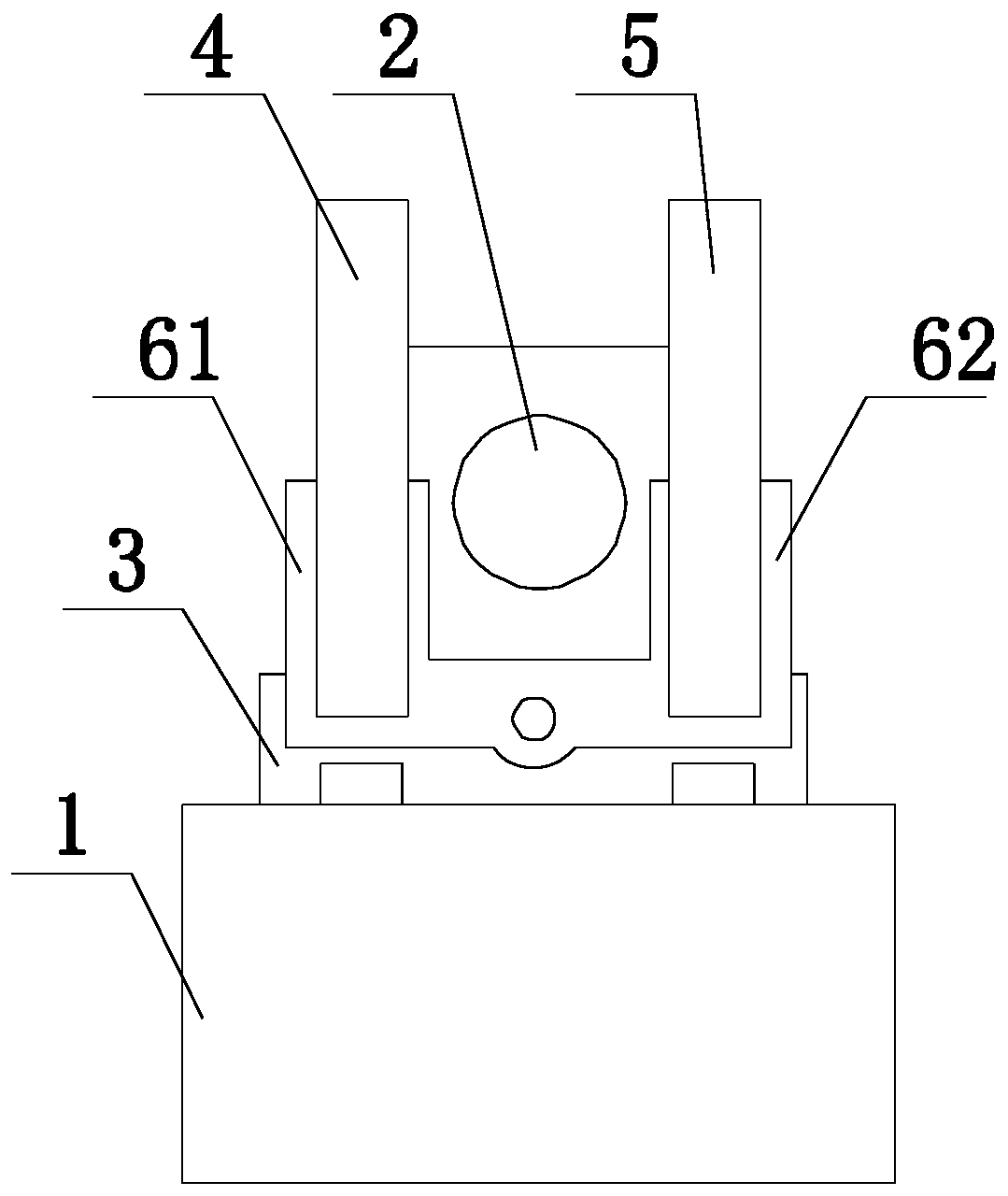

[0016] Such as figure 1 and 2 as shown, figure 1 It is a structural schematic diagram of a steerable forklift proposed by the present invention, figure 2 It is a top view structural schematic diagram of a steerable forklift proposed by the present invention.

[0017] refer to figure 1 and 2 , a kind of steerable lifting forklift that the present invention proposes, comprises: car body 1, cargo fork, lifting support mechanism 2;

[0018] The bottom of the car body 1 is provided with wheels, one side of the car body 1 is provided with a horizontally protruding support seat, the car body 1 is provided with a vertically extending lifting slide rail, and the lifting slide rail is provided with a sliding seat 3 that can be slidably installed. The sliding seat 3 is provided with a vertically arranged main shaft;

[0019] The pallet fork is located above the support seat, and the pallet fork includes the first fork arm 4, the second fork arm 5, the first support part 61, the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com