Lifting aids for drive shaft assembly

A technology of transmission shaft and auxiliary equipment, which is applied in the directions of transportation and packaging, load hanging components, etc., can solve the problems of high labor intensity, shaking of the transmission shaft assembly, poor reliability of the lifting of the transmission shaft assembly, etc., so as to reduce manual labor. Strength, the effect of ensuring the reliability of hoisting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The core of the present invention is to provide a hoisting aid for the transmission shaft assembly, which can reduce labor intensity and improve the hoisting reliability of the transmission shaft assembly.

[0027] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

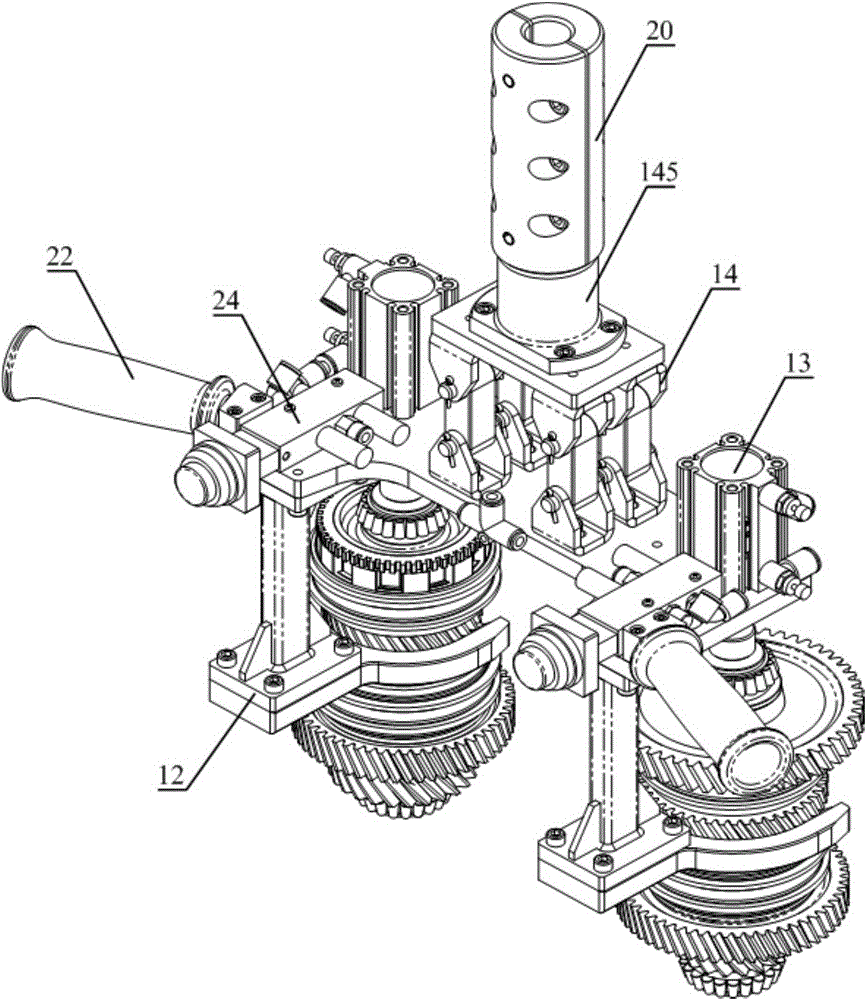

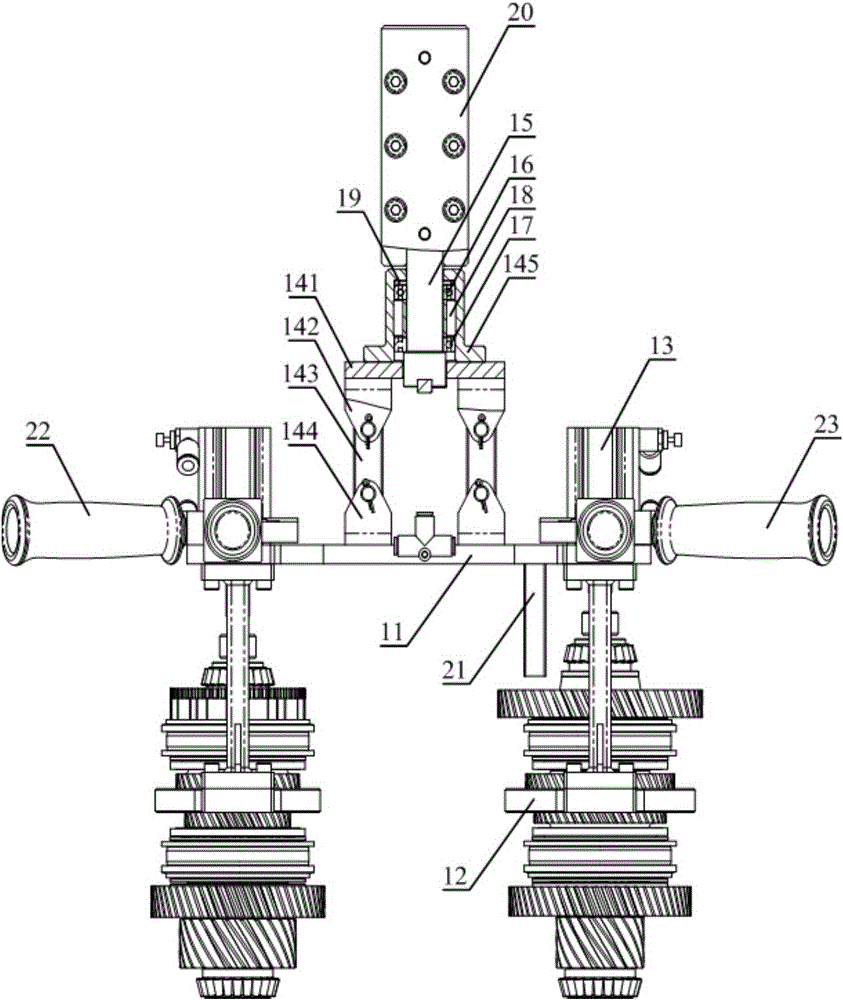

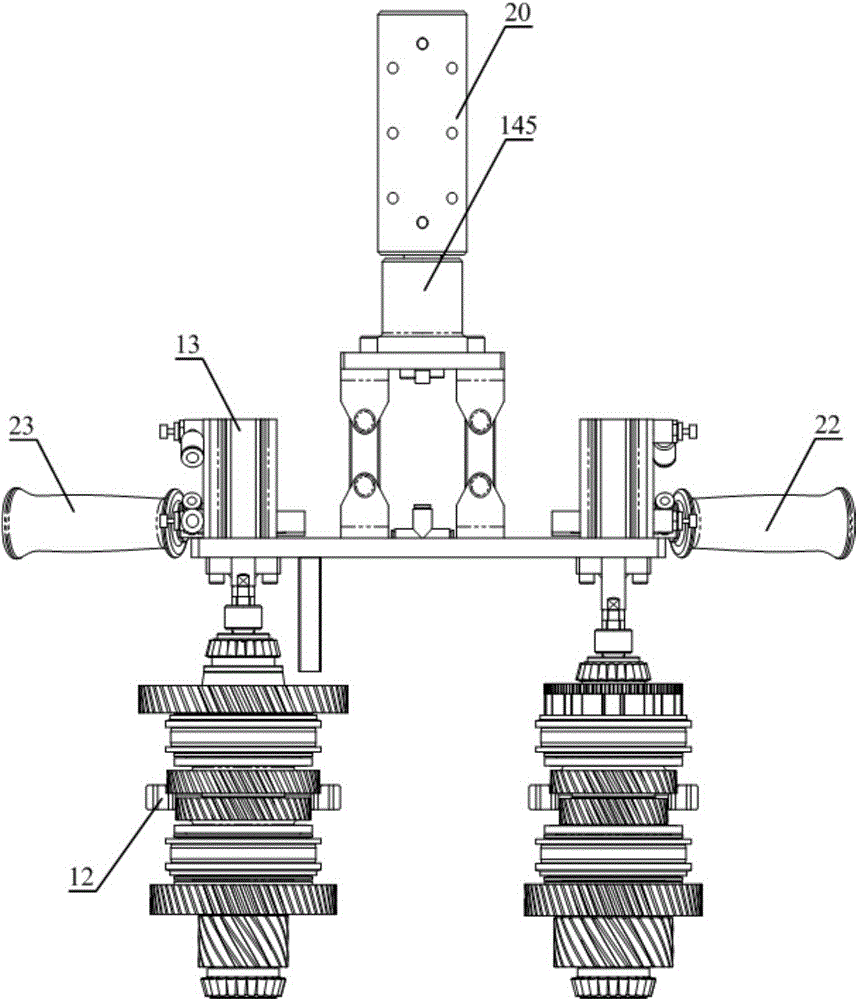

[0028] Such as Figure 1-5 As shown, the embodiment of the present invention provides a hoisting aid for the transmission shaft assembly, which can be used in conjunction with a sling, for example, to realize hoisting of the transmission shaft assembly after being connected with a pneumatic balance crane. The above-mentioned hoisting aids include a mounting frame 11 and a clamping and positioning part, the mounting frame 11 can be connected with the spreader, and the clamping and positioning part is arranged on the mounting frame 11, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com