Five-section telescopic conveyer

A telescopic and conveyor technology, applied in the direction of conveyor, transportation and packaging, can solve the problem that the thickness of the iron plate should not be too thick, and achieve the effect of small space occupation rate, long telescopic length and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further understand the content of the present invention, the present invention is described in detail in conjunction with examples, and the following examples are used to illustrate the present invention, but are not used to limit the scope of the present invention.

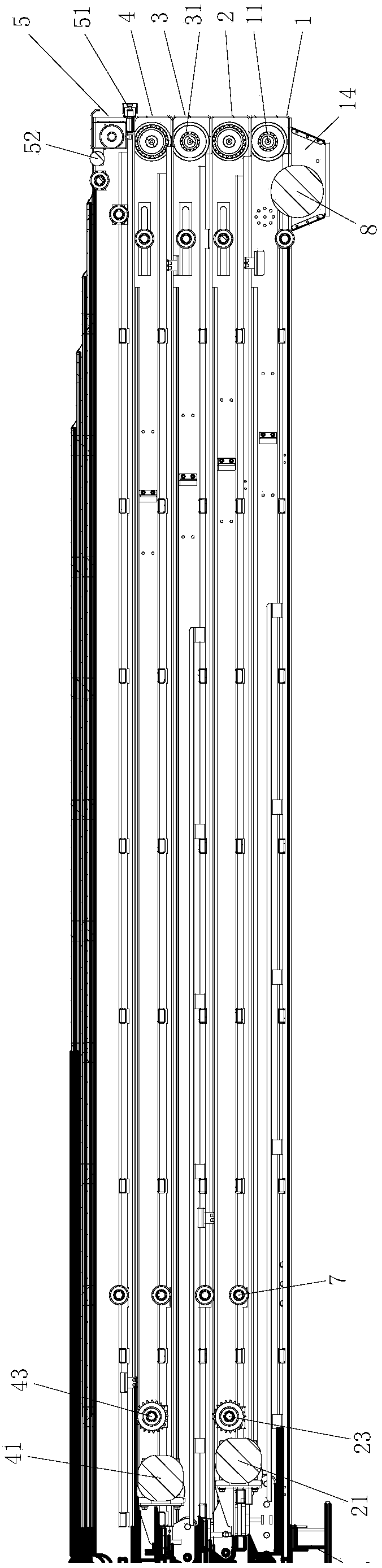

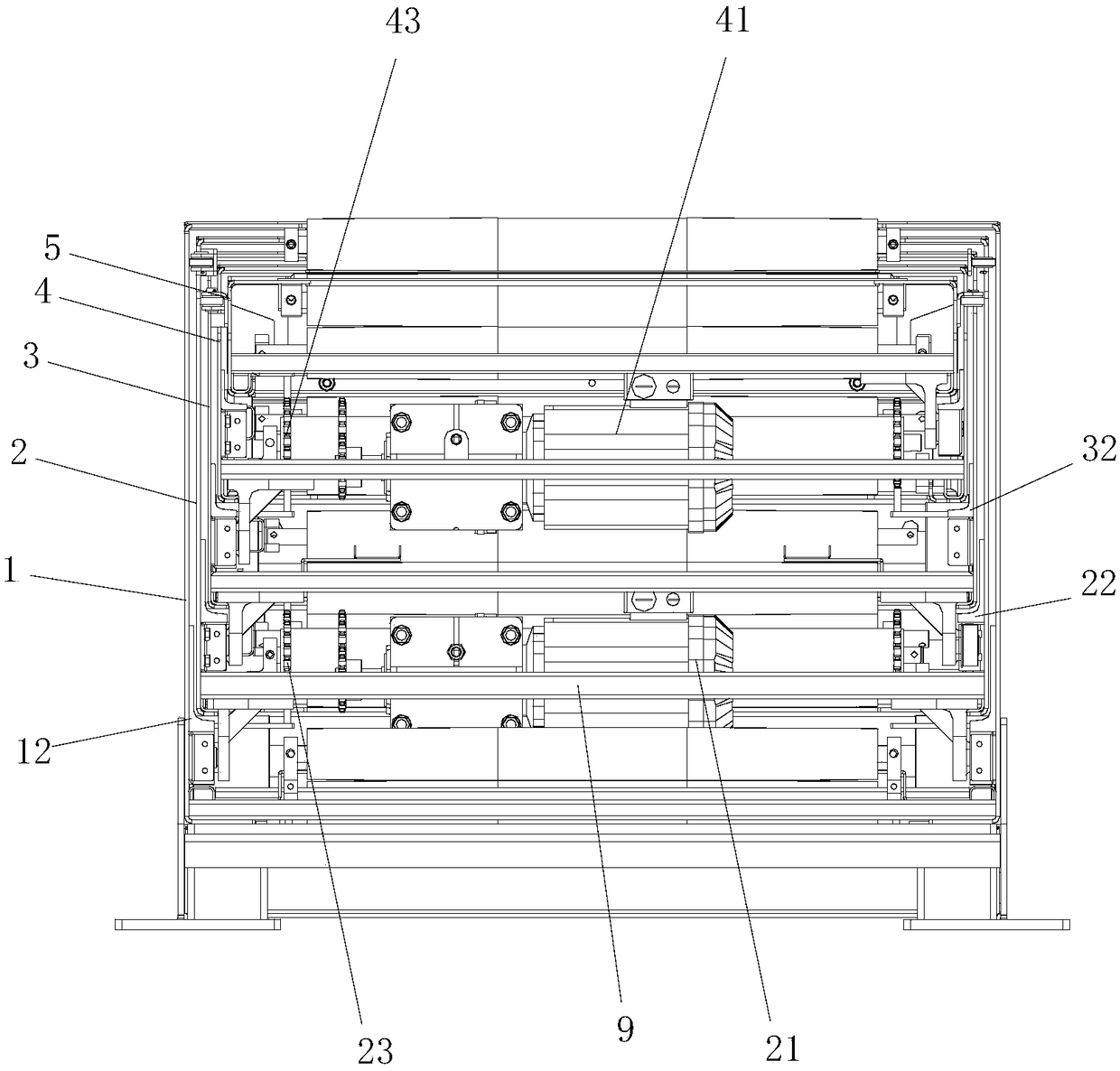

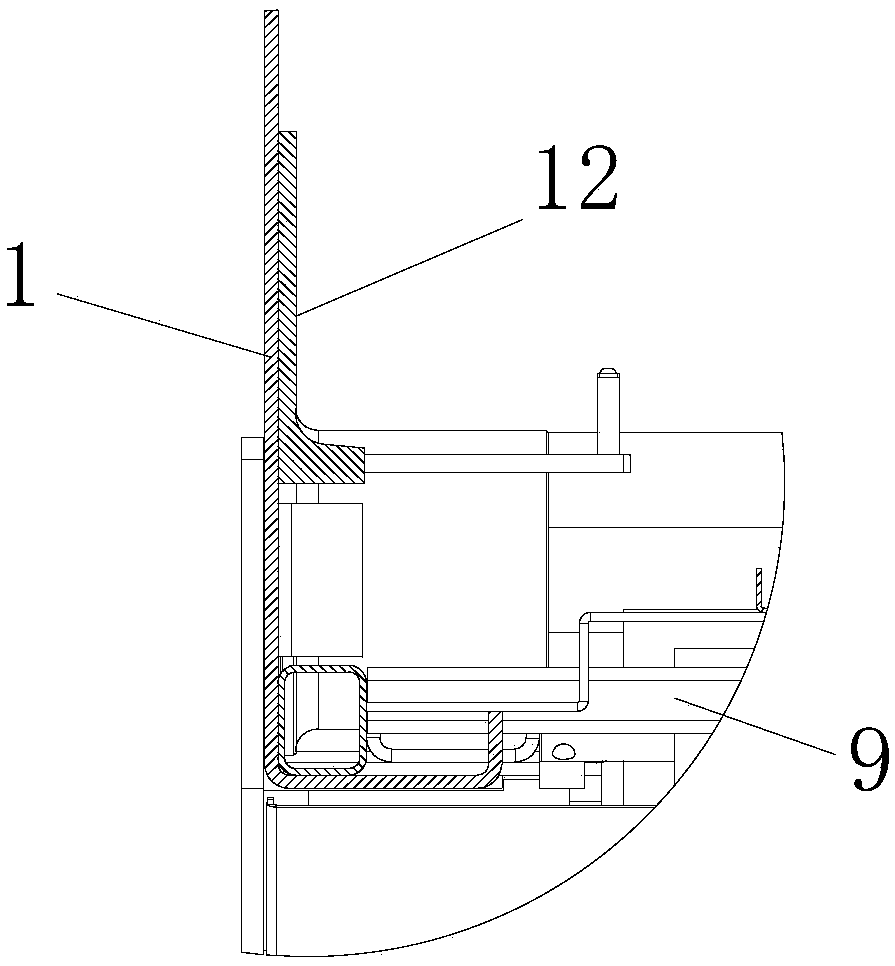

[0029] combined with figure 1 As shown, a five-section telescopic conveyor related to the present invention includes a first frame 1, a second frame 2, a third frame 3, a fourth frame 4 and a fifth frame 5, and the second frame is located at the first frame 2 1, the third frame 3 is set in the second frame 2, the fourth frame 4 is set in the third frame 3, the fifth frame 5 is set in the fourth frame 4, the above-mentioned first frame 1, second frame 2, The third frame 3 , the fourth frame 4 and the fifth frame 5 are equal in length, all of which are 5 m, wherein the rear end of the first frame 1 is fixed on the ground through a bracket 13 .

[0030] combined with Figure 1~2 As shown, the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com