Two-hole perforating device for food packaging box side wall paper board

A punching device and packaging box technology, applied in the field of punching machines, can solve the problems of uneven punching, unsightly, inconvenient use, etc., and achieve the effects of improving service life, quick and convenient use, and simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

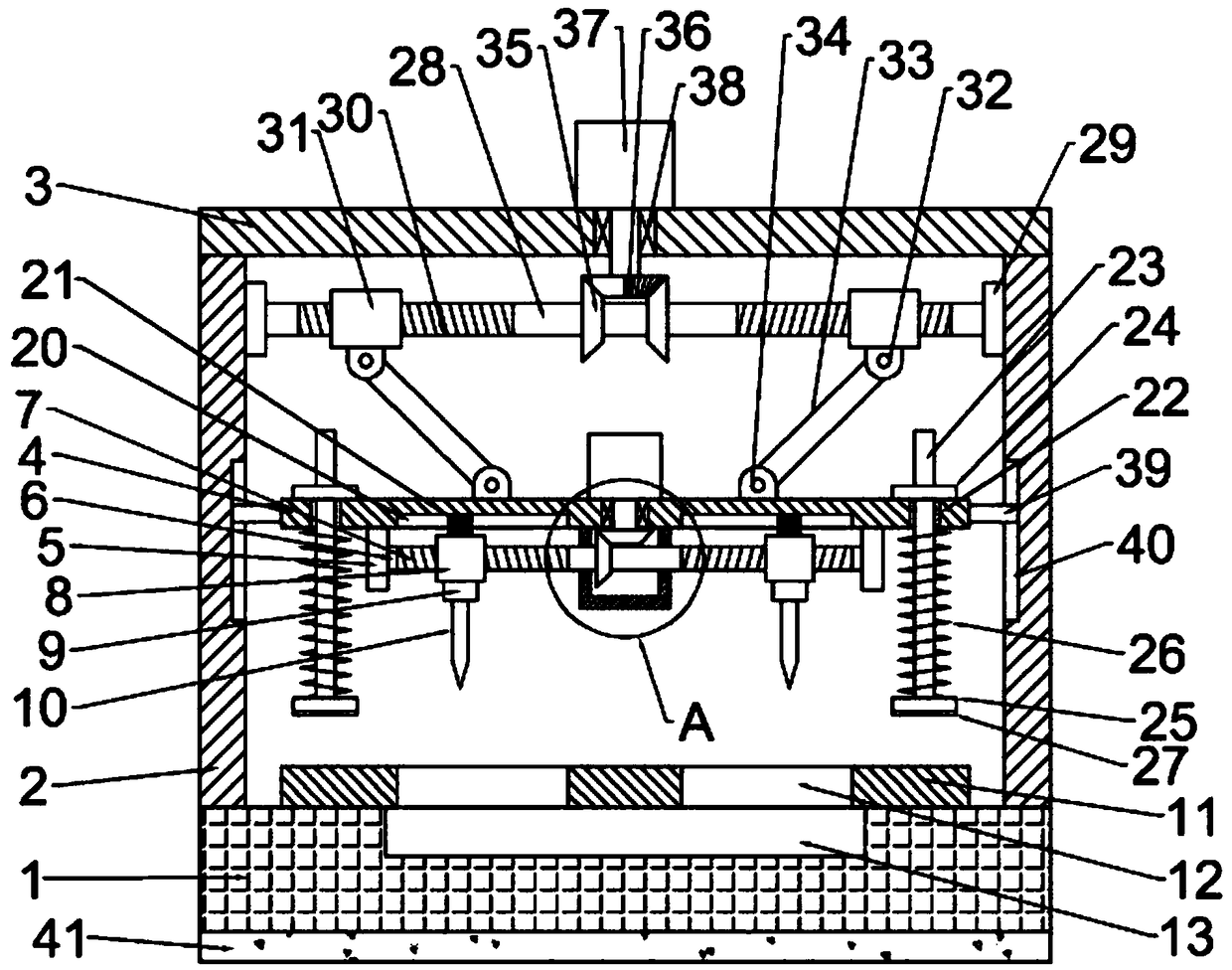

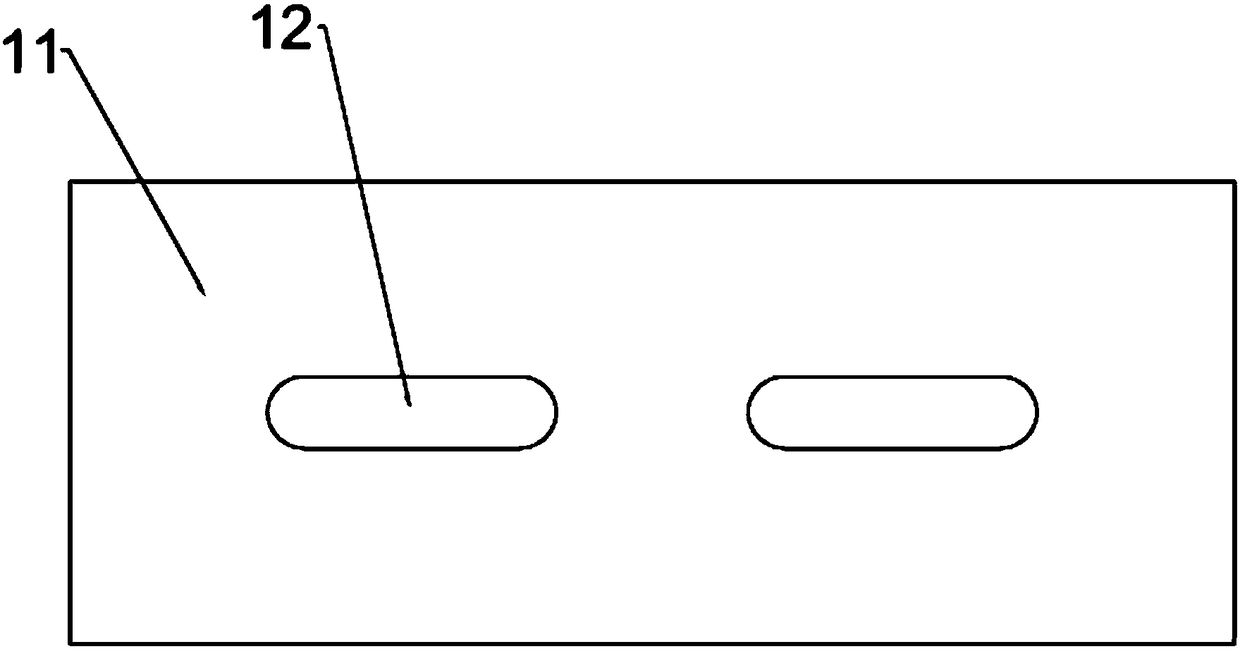

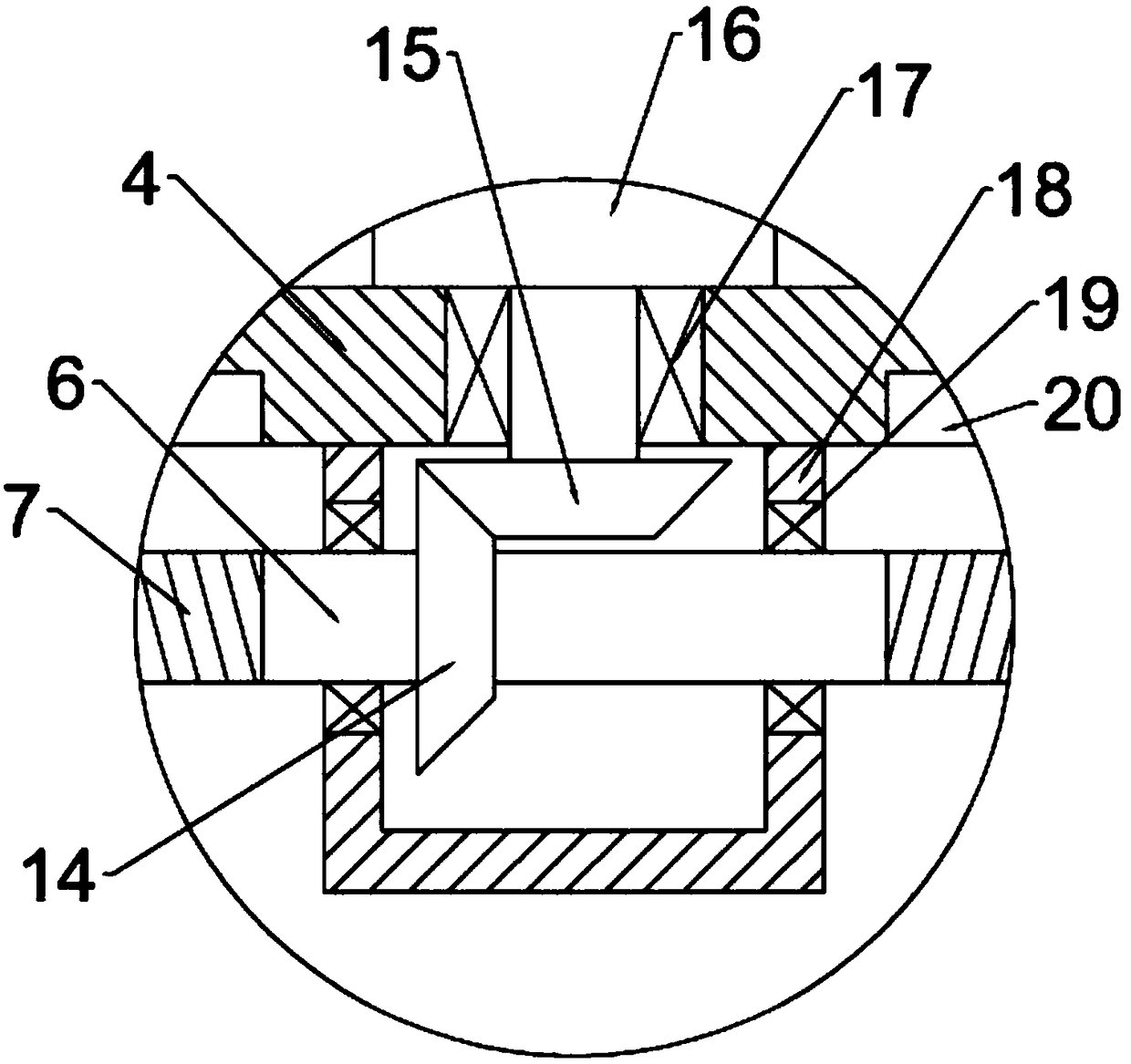

[0022] see Figure 1-3 , a double-hole punching device for side wall paper boards of food packaging boxes, including a base 1, support plates 2 are symmetrically installed on the left and right sides of the upper end of the base 1, the support plates 2 are perpendicular to the base 1, and the two support plates 2 are parallel to each other, a top plate 3 is installed on the upper end of the support plate 2, a lifting plate 4 is arranged between the top plate 3 and the base 1, the lifting plate 4 is parallel to the top plate 3, and the lower end surface of the lifting plate 4 is close to the left and right sides. Mounting blocks 5 are installed symmetrically, and a first adjustment shaft 6 is installed rotating between the two installation blocks 5. The two ends of the first adjustment shaft 6 are symmetrically provided with first threaded parts 7, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com