Vehicle-mounted integrated concrete stirring and pumping system

A technology for concrete and mixing pumps, which is applied in the direction of cement mixing devices, clay preparation devices, chemical instruments and methods, etc. It can solve the problems that the mixing efficiency cannot meet the requirements of concrete pumping efficiency, small capacity, small volume, etc., and achieve improved mixing and The effect of pumping efficiency, large capacity and high stirring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

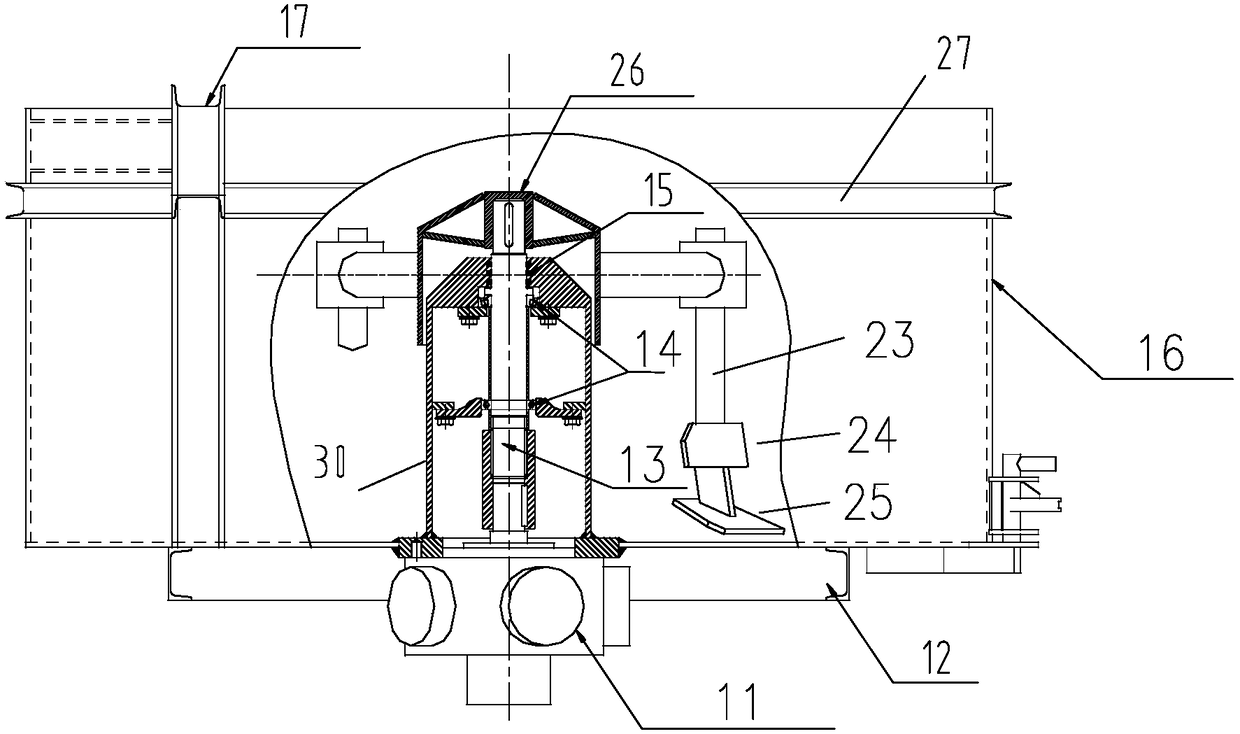

[0083] (1) Disc stirring device

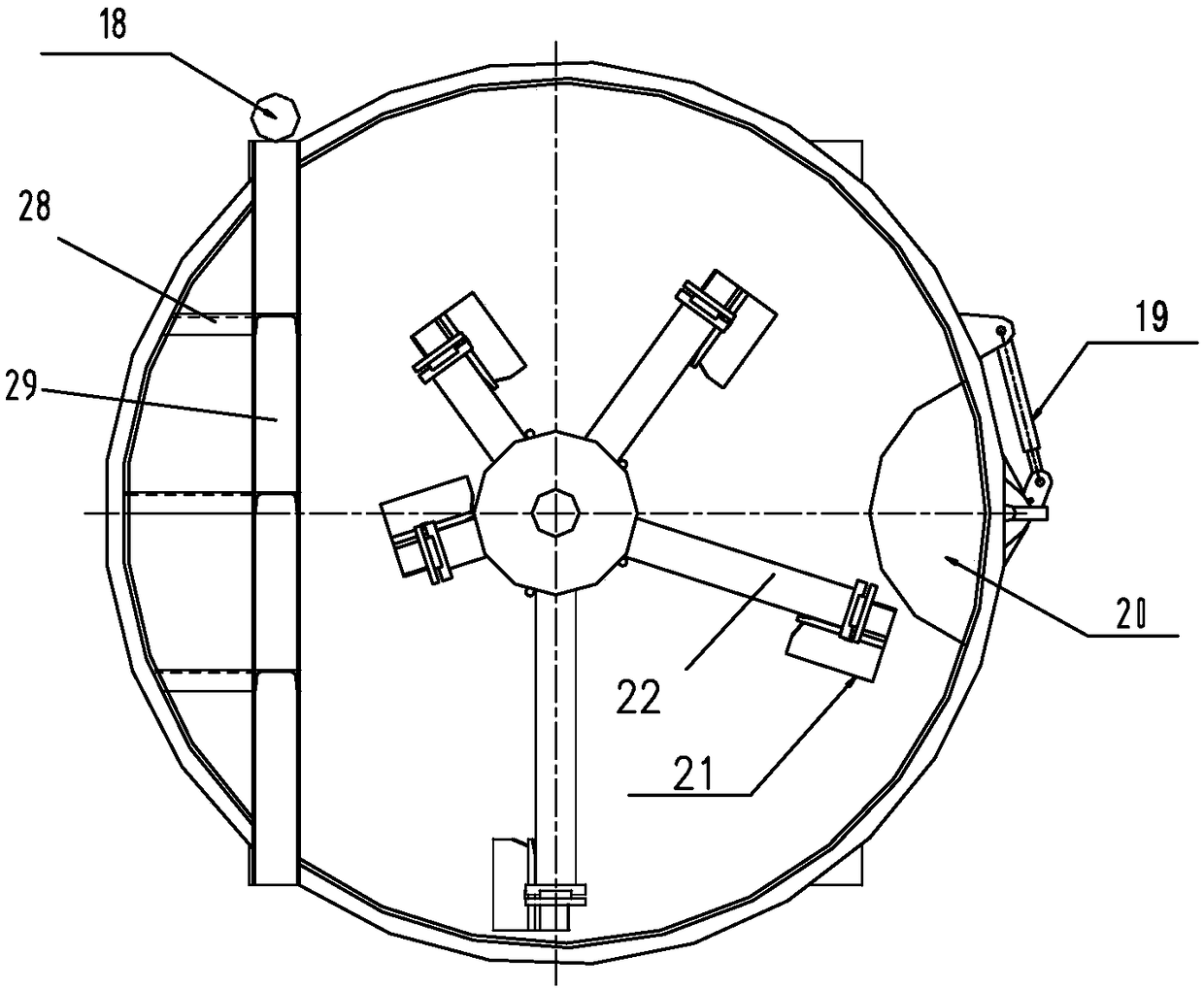

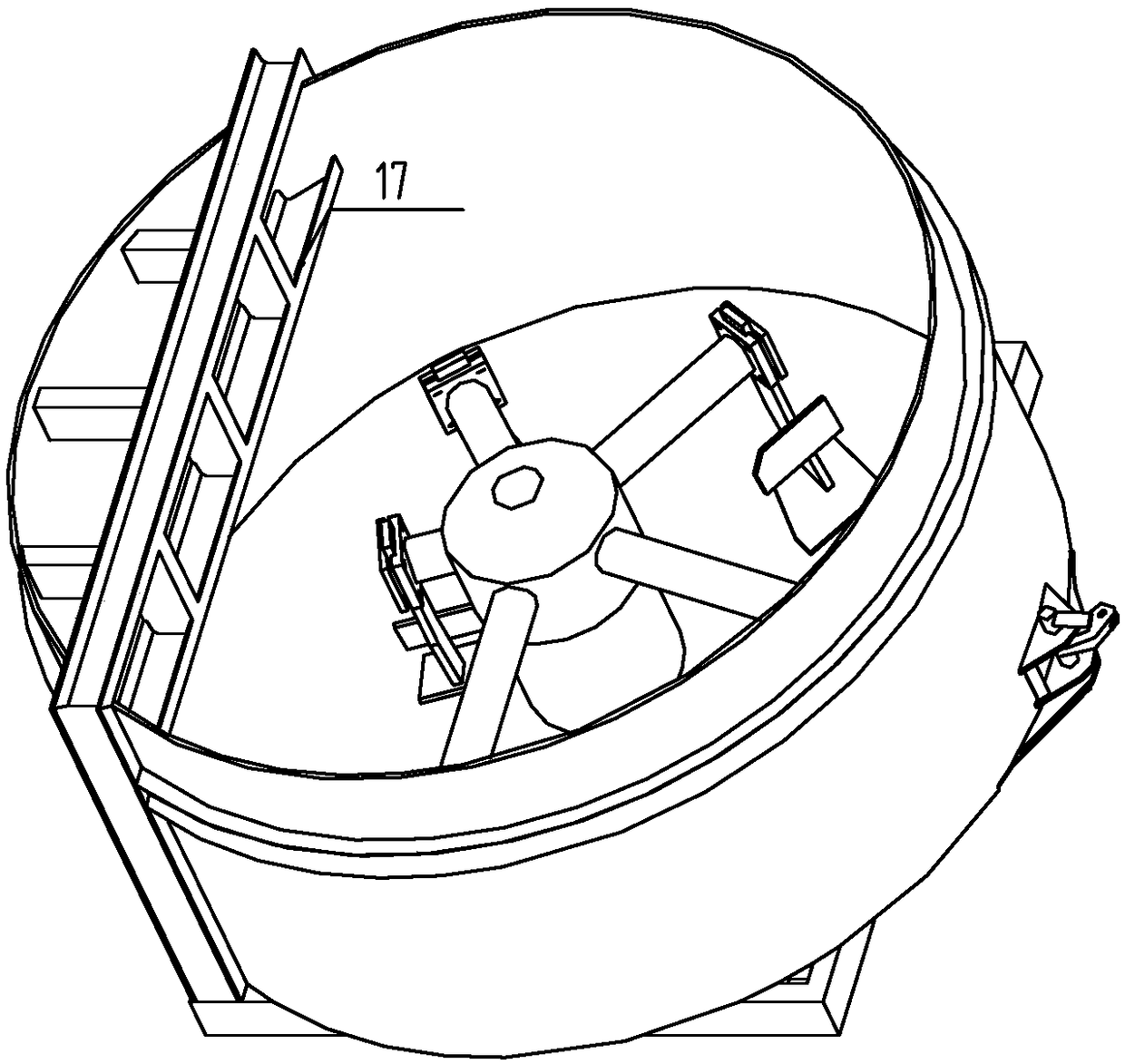

[0084] Such as Figure 1-3 , a disc type stirring device, comprising a stirring drum 16, a rotating shaft 13, a driving mechanism 11, a stirring arm 22 and a stirring assembly 21;

[0085] The mixing drum is cylindrical;

[0086] The rotating shaft is coaxial with the mixing drum; the rotating shaft is driven by the driving mechanism;

[0087] Five radial mixing arms 22 are arranged on the rotating shaft; the mixing knife assembly is installed on the mixing knife arm, and each mixing knife assembly is equipped with at least 2 pieces of mixing knives; the top of the rotating shaft can directly install the mixing knife arm, or the top of the rotating shaft There is a mixing knife arm mounting seat, which is fixedly connected with the rotating shaft and rotates synchronously, and the stirring knife arm is fixed on the stirring knife arm mounting seat;

[0088] There is a discharge mechanism at the bottom of the mixing drum;

[0089] The drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com