Concrete stirring equipment used for building and capable of obliquely stirring

A kind of mixing equipment and construction technology, applied in the field of concrete mixing equipment, can solve the problems of affecting the quality of building materials, limited mixing range, mixing dead angle, etc., and achieve the effect of improving building construction quality, improving mixing efficiency, and ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

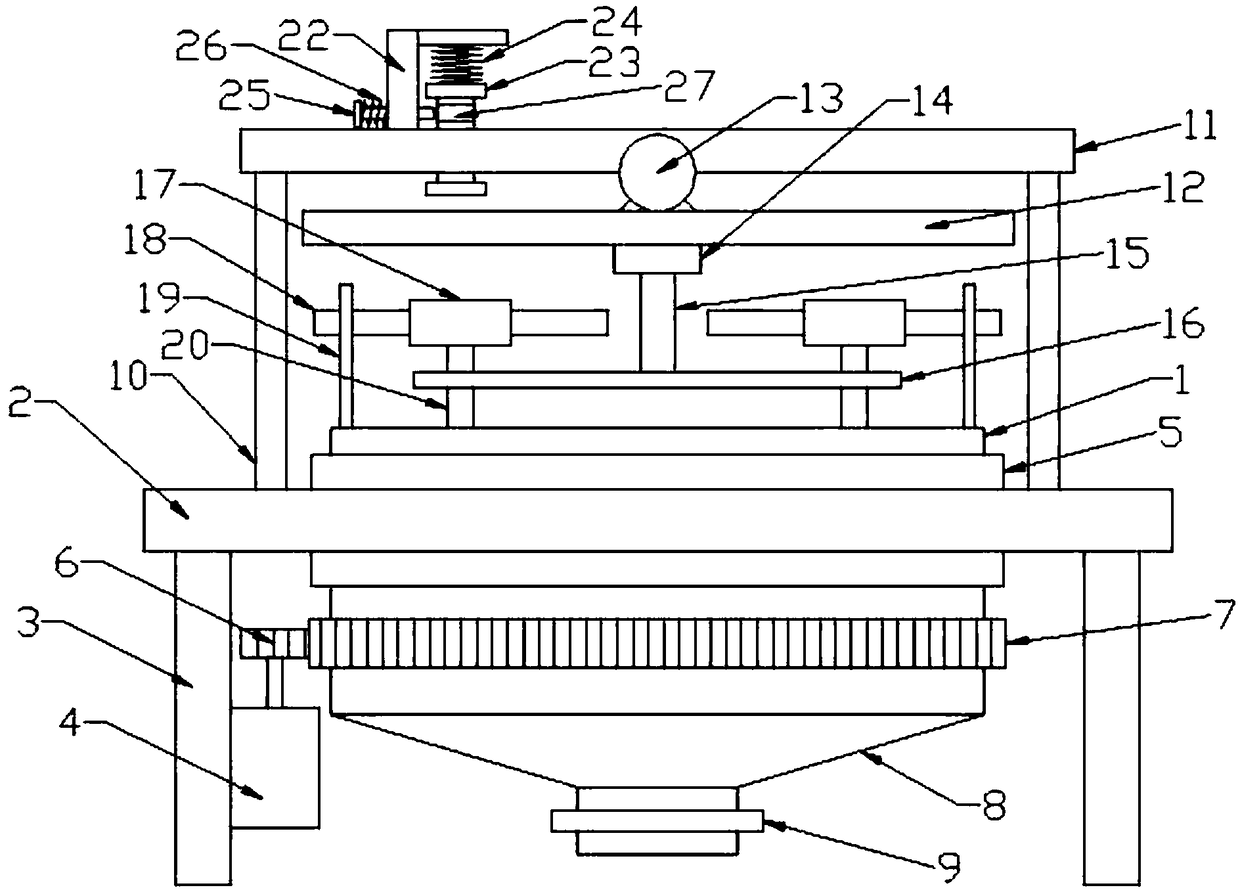

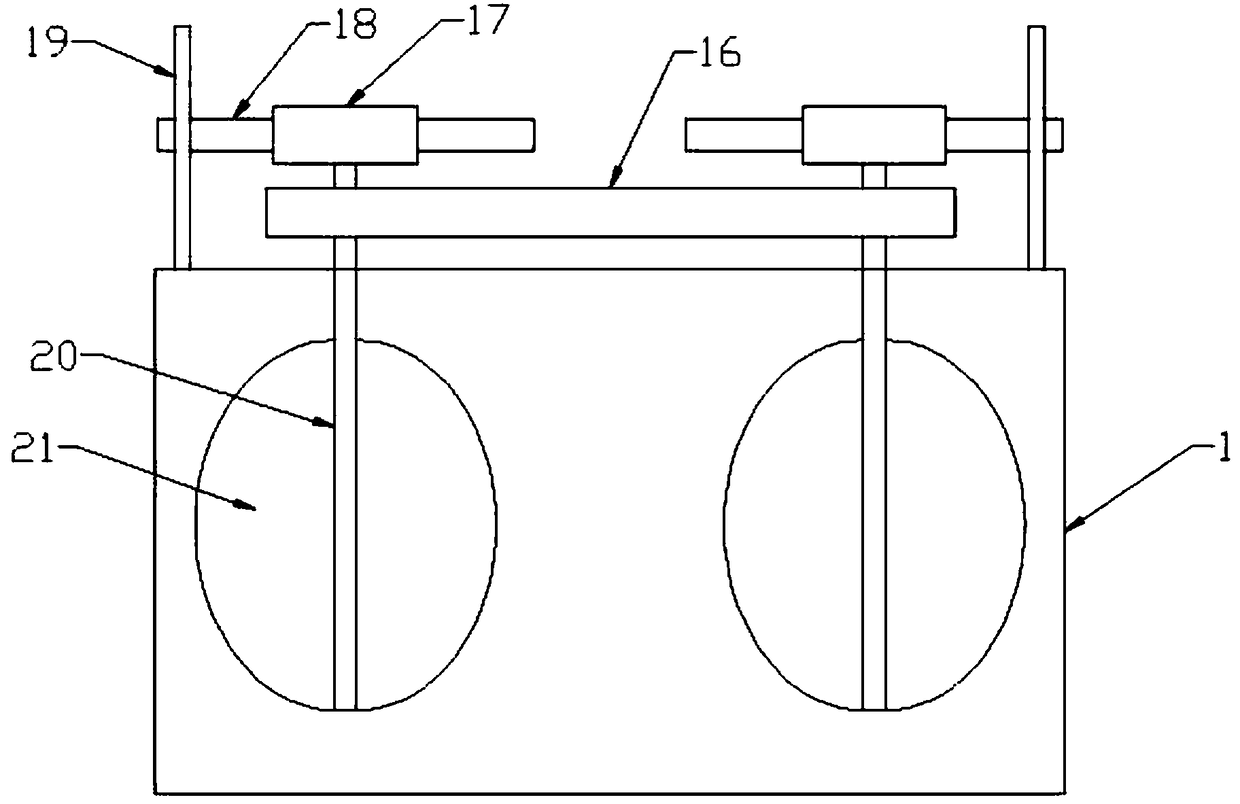

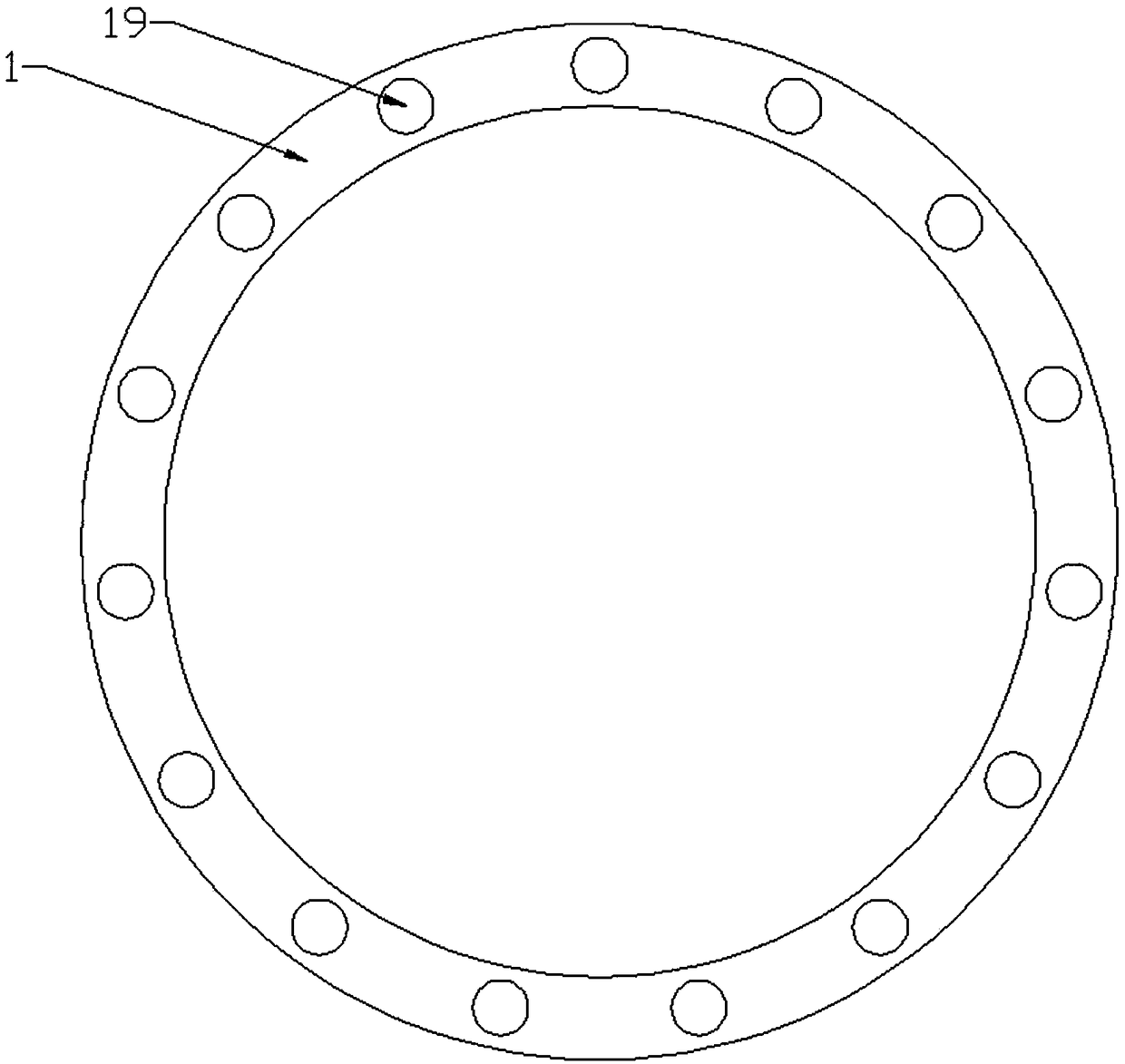

[0021] Referring to the drawings, in the embodiment of the present invention, a concrete mixing equipment that can be tilted and mixed for construction includes a barrel 1, an installation platform 2, a supporting leg 3, a motor 4, a rotating bearing 5 and a lower hopper 8; the supporting leg 3 is fixed on the lower side of the installation platform 2, supports the installation platform 2, the barrel body 1 is arranged in the installation platform 2, and the barrel body 1 is rotatably connected with the installation platform 2 through the rotating bearing 5, so that the barrel body 1 can be mounted on the installation platform 2. Rotating around the central axis, a lower hopper 8 is connected to the bottom of the barrel 1, the lower hopper 8 is a funnel-shaped structure, and the bottom screw of the lower hopper 8 is provided with a sealing cover 9, which is convenient for pouring out the mixed concrete; the motor 4 Fixed on the outrigger 3, the output shaft of the motor 4 is ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com