Threaded rod disassembling machine

A screw machine and screw technology, applied in the field of screw machine, can solve problems such as screw removal and scrapping work efficiency, save manpower and time, and solve the effect of plastic processors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

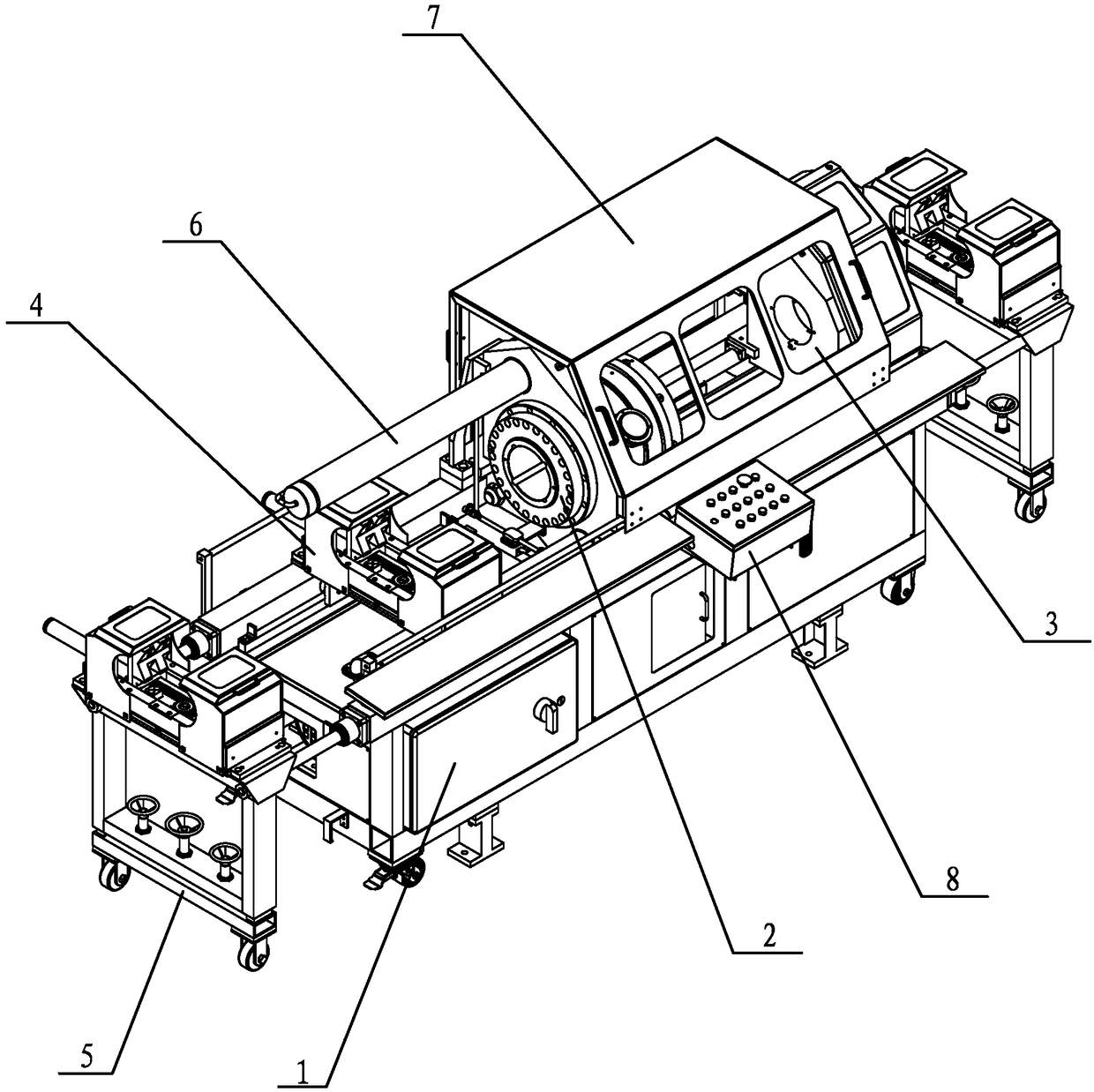

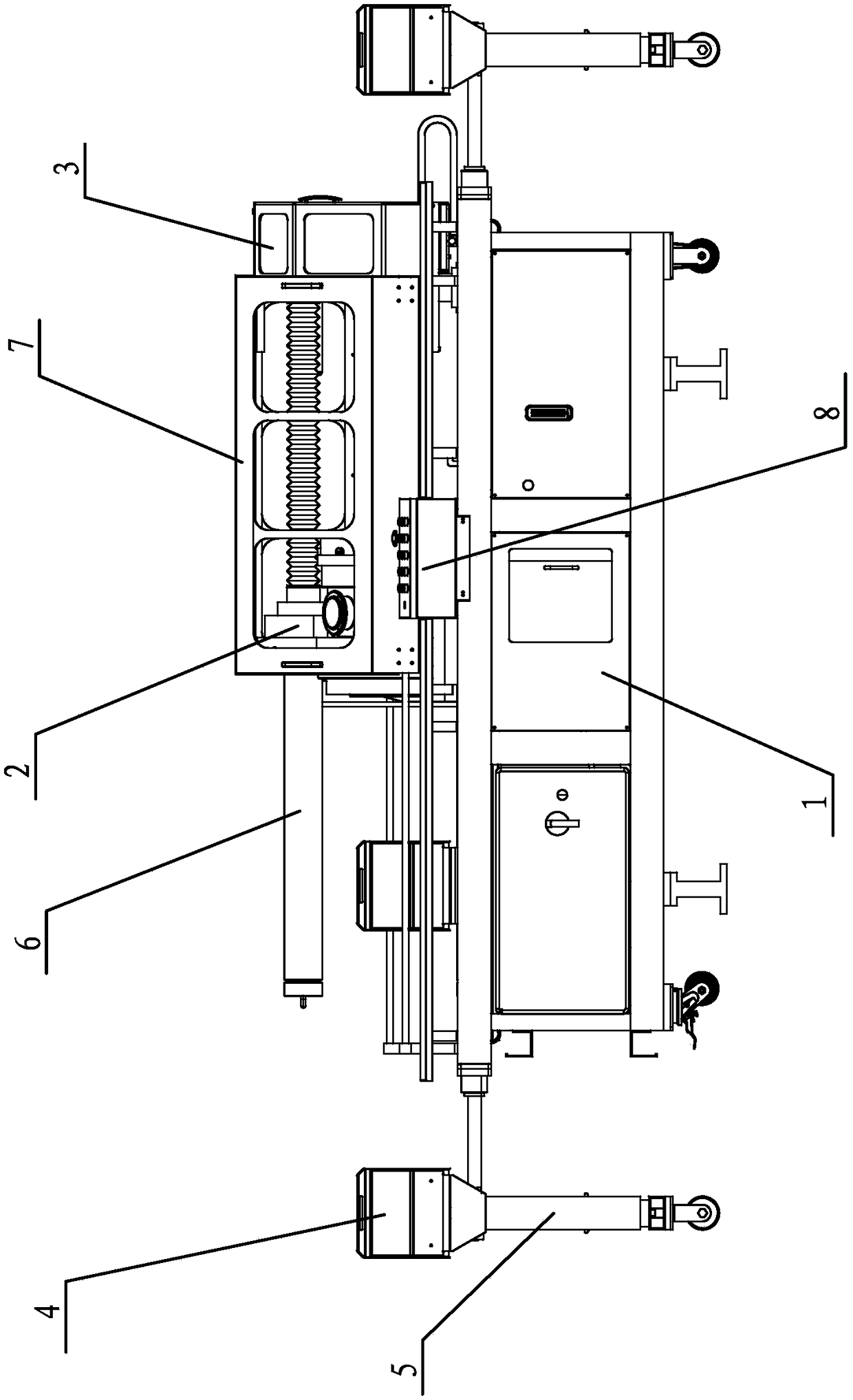

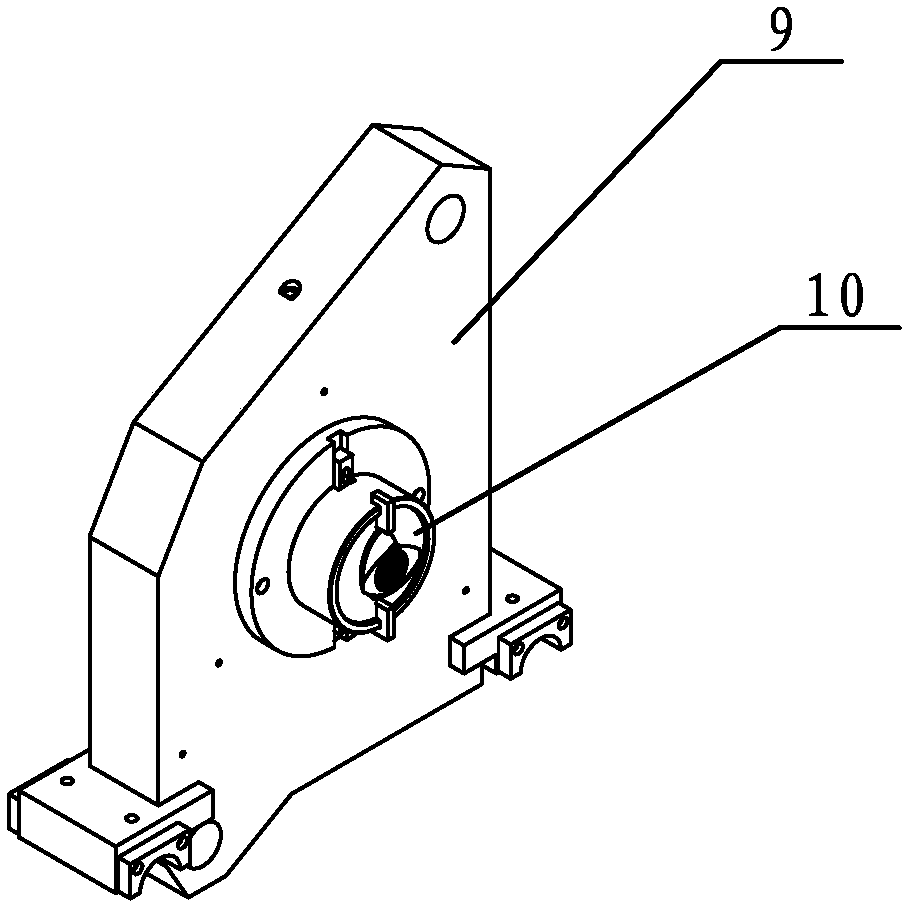

[0033] refer to figure 1 , figure 2 , the present invention provides a screw removal machine, comprising a fuselage 1, a slide rail is arranged on the fuselage 1, a first clamping device 2 and a second clamping device 3 are installed on the slide rail, and the fuselage 1 is also provided with There are a plurality of auxiliary clamping devices 4 .

[0034] The first clamping device 2 includes a hydraulic chuck, which is installed on the fuselage 1 through a screw rod, and its position can be adjusted by the screw rod. The hydraulic chuck is equipped with multiple jaws for clamping the screw. The jaws are concentrically linked and can clamp the screw from multiple directions at the same time, ensuring the balance of the applied force. The jaws are driven by hydraulic pressure and the action is stable. , to avoid damage to the screw. The first clamping device 2 is equipped with a propulsion cylinder 6 for pushing the second clamping device 3 , and the piston rod of the propu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com