Adjustable-angle stirring device for photocatalyst mixing and working method of stirring device

A stirring device and photocatalyst technology, applied in the field of photocatalyst, can solve the problems of uneven dispersion of mixture in the vertical direction, unsatisfactory stirring effect, and inability to meet vacuum sealing, etc., to achieve good sealing, good stirring effect, and uniform mixing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

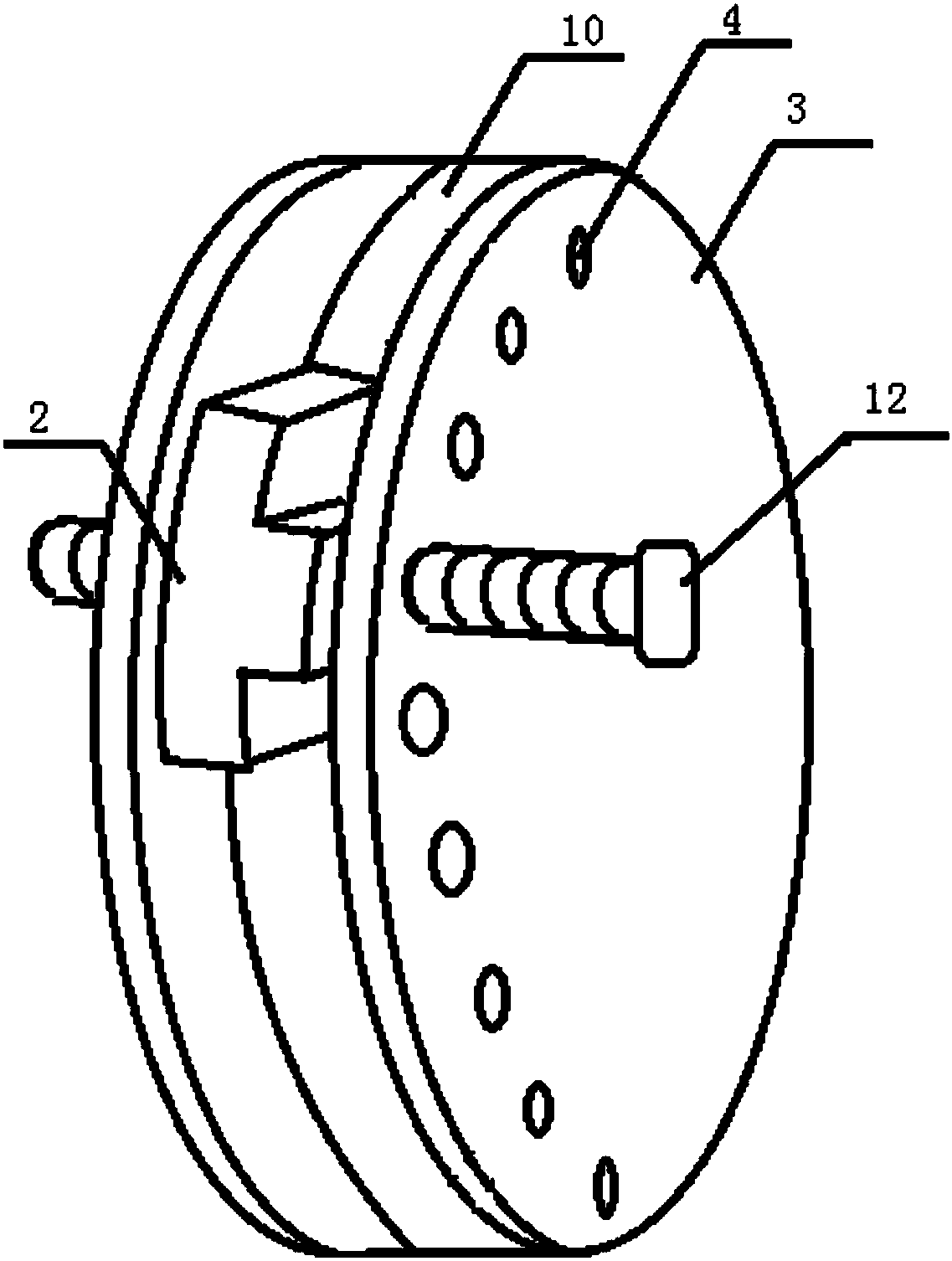

Embodiment 1

[0039] The above-mentioned stirring device is positioned at 30° to the horizontal plane through the through hole and the fixed hole pin on the support seat through the screw rod, Figure 6 It is a schematic diagram of the partial structure of the stirring paddle of the angle-adjustable stirring device in Embodiment 1. As shown in the figure, the angle α between the two blades of the long paddle is 0°. The edge of the paddle has a wave-shaped tooth plate, and a cross-shaped hole is opened in the middle of the paddle.

Embodiment 2

[0041] The above-mentioned stirring device is positioned at 45° to the horizontal plane through the through hole and the fixed hole pin on the support seat through the screw rod, Figure 7 It is a schematic diagram of the partial structure of the stirring paddle of the angle-adjustable stirring device in Embodiment 2. As shown in the figure, the angle α between the two blades of the long paddle is 30°. The edges of the paddles are provided with sawtooth-shaped tooth plates, and the middle of the paddles has a five-pointed star-shaped hole.

Embodiment 3

[0043] The above-mentioned stirring device is positioned at 60° to the horizontal plane through the through hole and the fixed hole pin on the support seat through the screw rod, Figure 8 It is a schematic diagram of the partial structure of the stirring paddle of the angle-adjustable stirring device in Embodiment 3. As shown in the figure, the angle α between the two blades of the long paddle is 45°. The edge of the paddle has a wavy tooth plate, and a triangular hole is opened in the middle of the paddle.

[0044] The angle-adjustable stirring device working method of above embodiment 1-3 is as follows:

[0045] (1) Select a suitable stirring paddle 8, insert it into the corresponding slot 15 of the stirring rod 7 according to the long paddle and the short paddle of the paddle, cover the end cover 17, and make the end cover 17 and the flange buckle 16 of the stirring rod 7 Fasten and fix;

[0046] (2) Insert the other end of the stirring rod 7 into the stirring part 6 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com