A heating control method for a food processor

A food processing machine and heating control technology, applied in the direction of temperature control, control/regulation system, non-electric variable control, etc., can solve the problem of uneven temperature of the upper and lower parts of the slurry, long pulping cycle, too small selection of heating tube power, etc. It can shorten the pulping cycle, avoid the phenomenon of bottom paste, and improve the temperature measurement accuracy and pulping effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

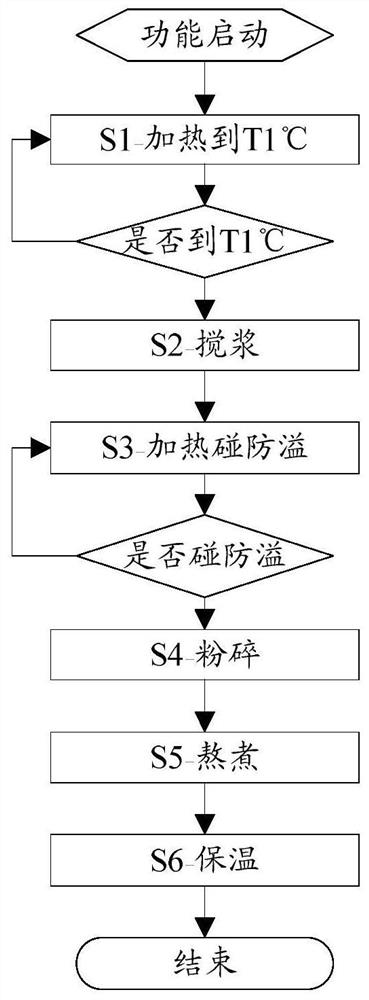

[0052] A heating control method of a food processor, the food processing process of the food processor is divided into a plurality of continuous processing stages, the food processor includes a plurality of heating devices, wherein at least one heating device is arranged on the cup of the food processor body bottom, at least one heating device is set on the side of the cup body of the food processor, such as figure 1 As shown, the method may include step S11:

[0053] S11. For different processing stages in the plurality of processing stages, use heating devices at different positions to heat in different heating methods.

[0054] In the embodiment of the present invention, based on the fact that a single heating device is used for heating in current food processors, it is easy to cause longer pulping cycle and pulp overflow phenomenon. And when the single heating device (such as a single heating tube) is installed on the bottom of the cup body, the temperature of the upper a...

Embodiment 2

[0065] On the basis of Example 1, the heating control modes of each processing stage were optimized.

[0066] Optionally, for different processing stages in multiple processing stages, using heating devices at different positions to heat in different heating methods may include:

[0067] In the full-power heating stage, use two heating devices to work in parallel, and / or use a heating device installed on the side of the cup body for separate heating for heating;

[0068] In the stirring stage and crushing stage, two heating devices work in series for heating, and / or use the heating device installed at the bottom of the cup body for separate heating;

[0069] In the heating and anti-overflow stage, the boiling stage and the heat preservation stage, two heating devices are used to work in series, and / or the heating device arranged on the side of the cup body is used to heat independently.

[0070] In the embodiment of the present invention, the full-power heating stage needs to...

Embodiment 3

[0074] On the basis of the second embodiment, the heating control mode in the full power heating stage is introduced in detail.

[0075] Optionally, the full-power heating phase includes: a water level detection sub-phase, a temperature judgment sub-phase and a formal heating sub-phase;

[0076] In the full-power heating stage, the method of using two heating devices to work in parallel, and / or using the heating device installed on the side of the cup body for separate heating, may include:

[0077] In the sub-stage of water level detection, two heating devices are used to work in parallel to continuously heat H1 for a period of time to detect whether there is water in the food processor;

[0078] In the temperature judgment sub-stage, stop heating H2 for a period of time to detect and judge the initial water temperature; and,

[0079] In the formal heating sub-stage, use two heating devices to work in parallel to heat the water to the preset first temperature; or use two hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com