X-ray source device

A technology of X-ray and source devices, applied in X-ray equipment, electrical components, etc., can solve problems such as complex design, weak signal, and difficult processing of vacuum tubes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

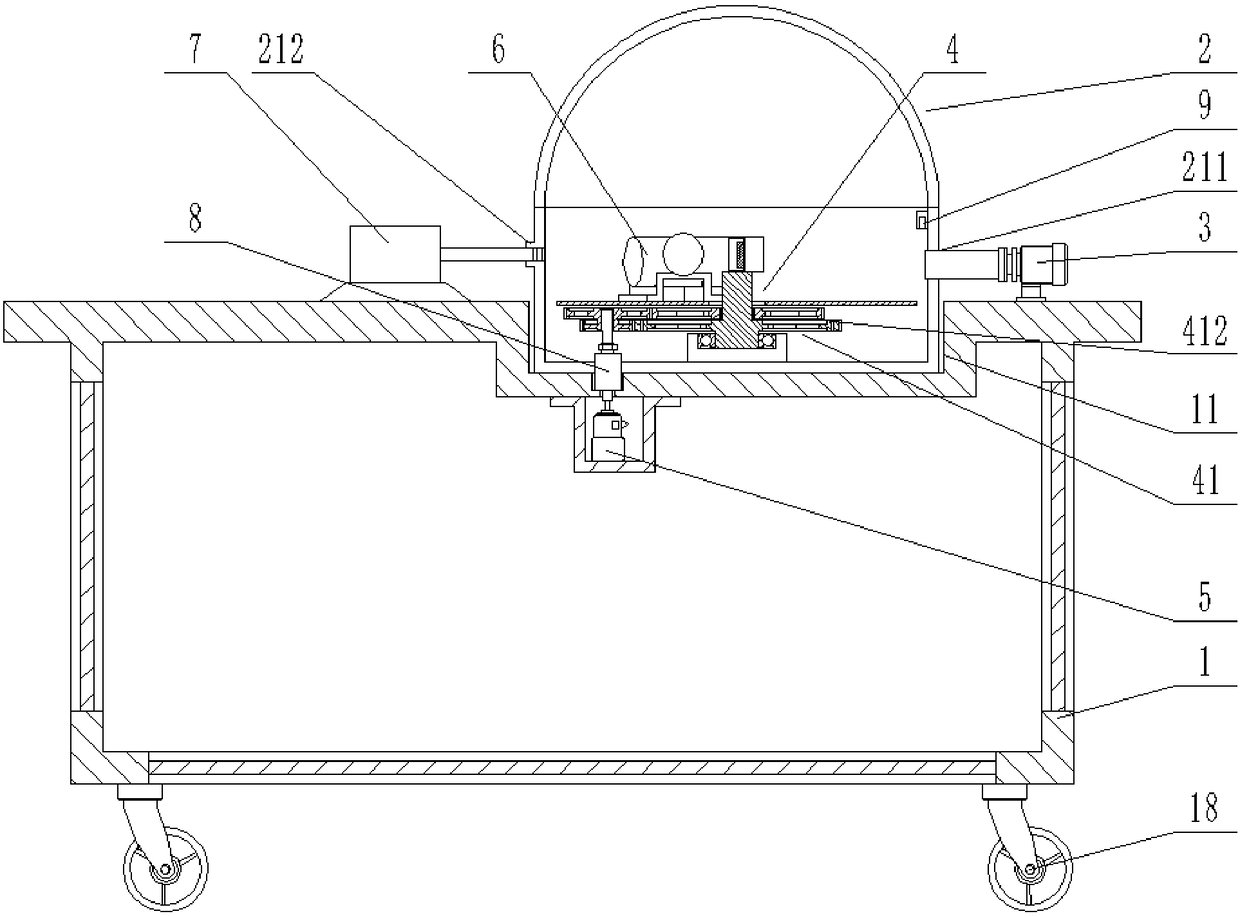

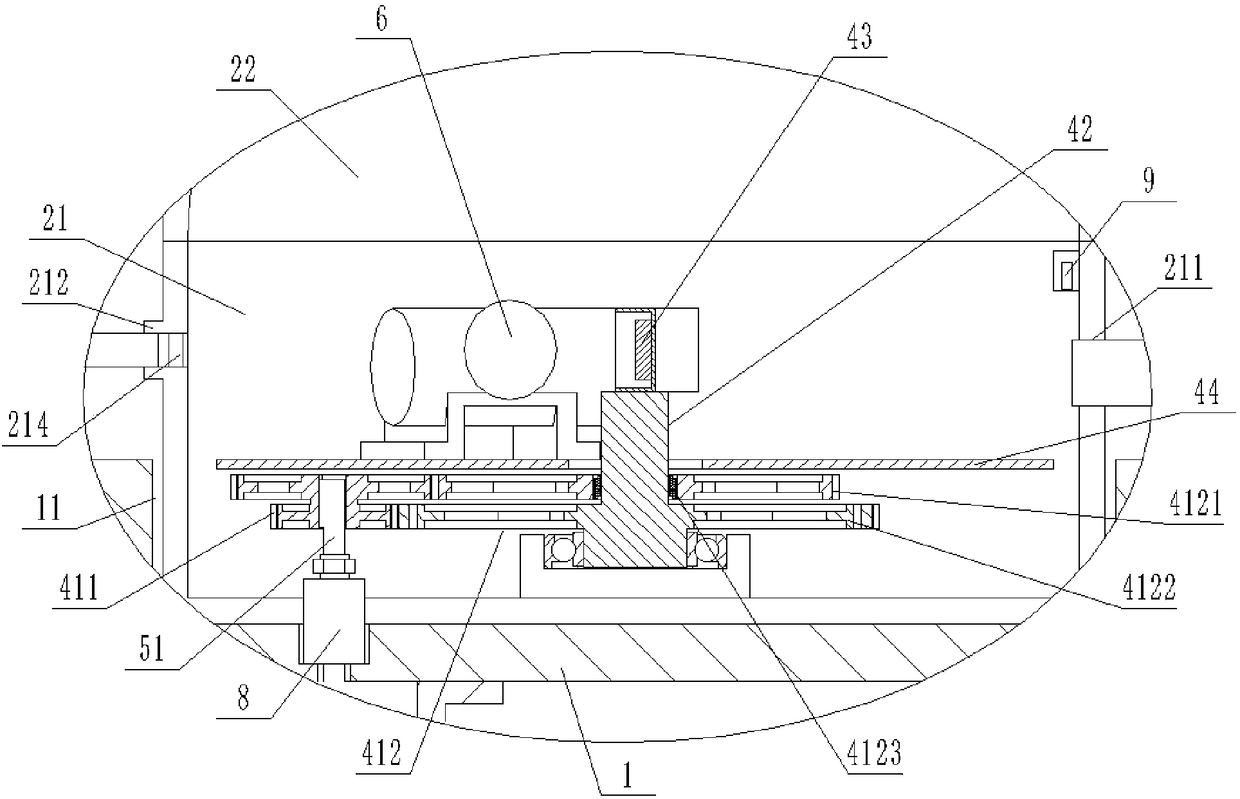

[0040] figure 1 , figure 2 They are respectively a structural schematic diagram and a partially enlarged view of the X-ray source device provided in Embodiment 1 of the present invention. combine figure 1 and figure 2 Shown:

[0041] The X-ray source device provided in Embodiment 1 of the present invention specifically includes: an installation base 1, a vacuum chamber 2, a dry pump 3, a single crystal monochromator 4, a drive motor 5, an open X-ray machine 6, an X-ray detector 7, Magnetic fluid seal 8, vacuum degree detector 9 and universal wheel 18.

[0042] Specifically, a fixing groove 11 is formed on the upper surface of the installation base 1 , and the vacuum chamber 2 is installed in the fixing groove 11 . Wherein, the vacuum chamber 2 includes a column cavity 21 and a hemispherical cavity 22, the column cavity 21 and the hemispherical cavity 22 are hermetically connected, and the column cavity 21 is provided with a connection port 211 and a window 212 in the ci...

Embodiment 2

[0059] Figure 5 , Figure 6 , Figure 7 and Figure 10 Respectively, the working state structural diagram and partial enlargement of the X-ray source device provided by Embodiment 2 of the present invention Figure 1 , partial enlargement Figure II And the schematic diagram of the top view of the non-working state. combine Figure 5 , Figure 6 , Figure 7 and Figure 10 Shown:

[0060] The X-ray source device provided in Embodiment 2 of the present invention specifically includes: a mounting base 1, a vacuum chamber 2, a plurality of outlet windows 212, a dry pump 3, a single crystal monochromator 4, a drive motor 5, an open X-ray machine 6, X-ray detector 7, arc track 12, driving trolley 13, placement plate 14, fixed frame 15, fixed ring 17, magnetic fluid seal 8, vacuum degree detector 9 and universal wheel 18.

[0061] Specifically, a fixing groove 11 is formed on the upper surface of the installation base 1 , and the vacuum chamber 2 is installed in the fixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com