Lead processing device and semiconductor device manufactured using the same

A technology for processing equipment and semiconductors, which is applied in the fields of semiconductor devices, semiconductor/solid-state device manufacturing, and semiconductor/solid-state device components, etc., and can solve the problems of inability to remove connecting rods and resin burrs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

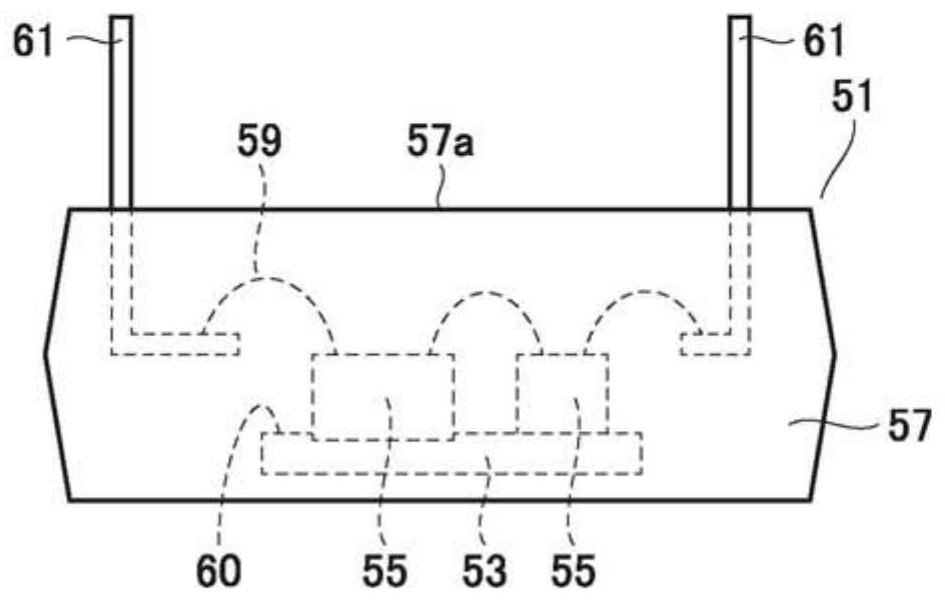

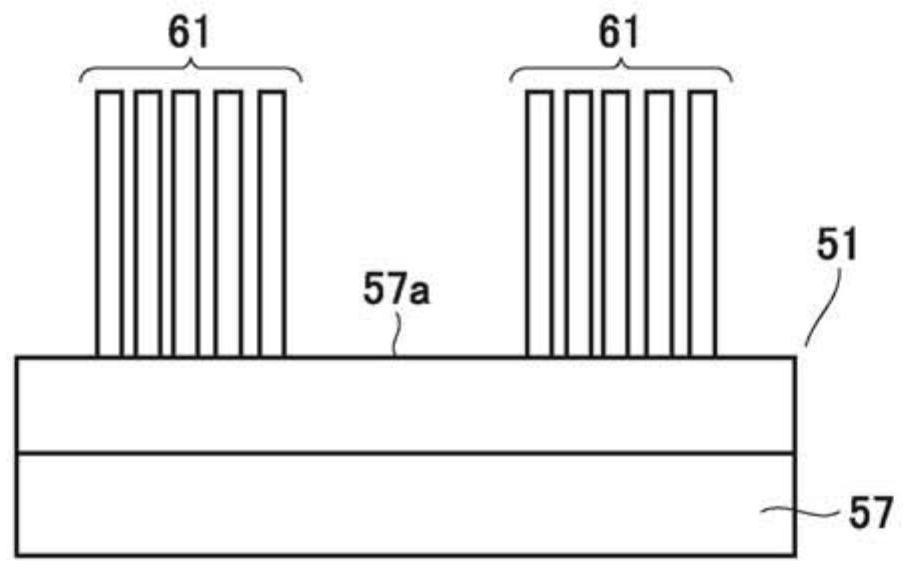

[0086] First, the basic concept of the lead processing device according to Embodiment 1 will be described using schematic diagrams. Such as Figure 14 As shown, in the lead processing device 1, the resin-molded semiconductor device 51 is arranged such that the surface 57a of the sealing resin body 57 faces upward, and the direction (first direction) in which the external terminal 61 protrudes from the surface 57a becomes upward ( Encapsulation resin body 57). The template 5 is inserted between the opposing external terminal 61 and the other external terminal 61 , and the template 5 is arranged to face the external terminal 61 on the side of the external terminal 61 .

[0087] Moreover, the release plate 7 is arrange|positioned so that it may oppose the plate|plate 5 with a distance from the external terminal 61. As shown in FIG. Here, the template 5 and the release plate 7 are arranged so that a gap is provided between the template 5 and the external terminal 61 , and a gap ...

Embodiment approach 2

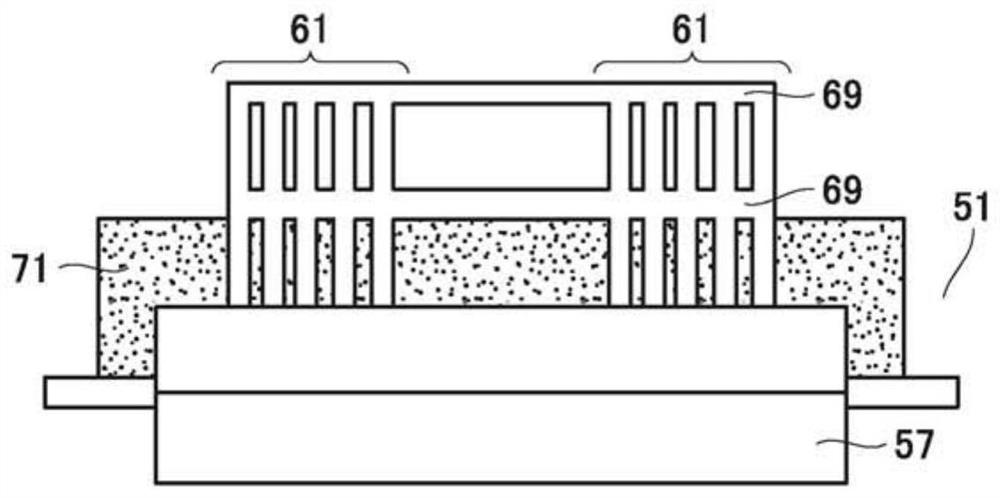

[0125] First, the basic concept of the lead processing device according to Embodiment 2 will be described using schematic diagrams. Such as Figure 29 As shown, in the lead processing device 1, the resin-molded semiconductor device 51 is arranged such that the surface 57a of the sealing resin body 57 faces upward, and the direction (first direction) in which the external terminal 61 protrudes from the surface 57a becomes upward ( Encapsulation resin body 57). The template 5 and the release plate 7 are arranged so that the external terminals 61 are sandwiched between the template 5 and the release plate 7 to pressurize the resin-molded semiconductor device 51 that has been placed.

[0126] In this state, the connecting rod 69 and the resin burr 71 are cut off by moving the punch 41 toward the template 5 in a direction intersecting with the protruding direction of the external terminal 61 (second direction). An insertion hole 5a through which the punch 41 is inserted to discha...

Embodiment approach 3

[0145] First, the basic concept of the lead processing device according to Embodiment 3 will be described using schematic diagrams. Such as Figure 35 As shown, in the lead wire processing device 1, the resin package is arranged such that the surface 57a of the package resin body 57 faces the lateral direction, and the direction (first direction) in which the external terminal 61 protrudes from the surface 57a becomes the lateral direction (X-axis negative direction). type semiconductor device 51 (encapsulating resin body 57). The template 5 is inserted between the opposing external terminal 61 and the other external terminal 61 , and the template 5 is arranged to face the external terminal 61 directly below or directly above the external terminal 61 . The release plate 7 is disposed so as to sandwich the external terminal 61 with the plate 5 .

[0146] In this state, the connecting rod 69 and the resin burr 71 are cut off by moving the punch 41 toward the die plate 5 in a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com