Self-inspection method and system for sensors of industrial furnaces and boilers

A sensor and industrial furnace technology, which is applied to the structural details of instruments, scientific instruments, gas analyzers, etc., can solve the problem of high cost of installation and layout equipment, and achieve the effect of convenient self-inspection and improved accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

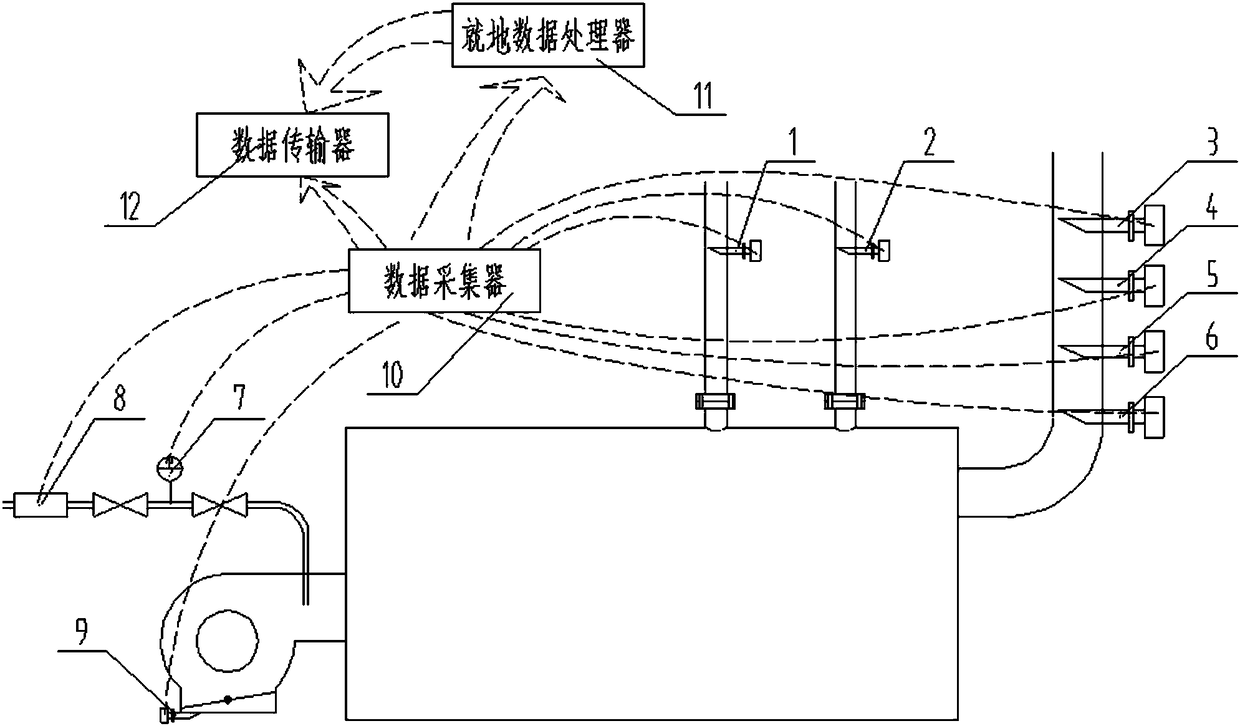

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0020] The present invention is used for the sensor self-inspection method of industrial furnaces and boilers, which is different from the prior art in which the detection values between sensors of the same type are used to verify each other, and is also different from the prior art in which paired sensors are set at the same detection point , but start from the whole sensor system to build a data relationship network. The data of different detection points are related to the operation status of the entire boiler and irrelevant, and there are data correlations and non-correlations between different detection points. The method of the present invention models the above-mentioned relationship network from the aspect of data relevance in a direction different from the conventional thinking, and mainly divides into the following four types of mathematical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com